Researchers at the Massachusetts Institute of Technology (MIT) have used 3D printing to create unique plasma sensors with the potential to help scientists better understand the impact of climate change.

Compared to traditional weather-monitoring sensors, the team’s laser cut and 3D printed alternative can be produced outside of cleanroom conditions, reducing its lead time from weeks down to just a few days. This, alongside their relatively low manufacturing cost, could make the devices ideal for fitting to CubeSats, where they can monitor temperature fluctuations in Low Earth Orbit (LEO).

“Additive manufacturing can make a big difference in the future of space hardware,” says MIT Principal Scientist, Luis Fernando Velásquez-García. “Some people think that when you 3D print something, you have to concede less performance. “But we’ve shown that is not always the case. Sometimes there is nothing to trade off.”

Making monitoring more accessible

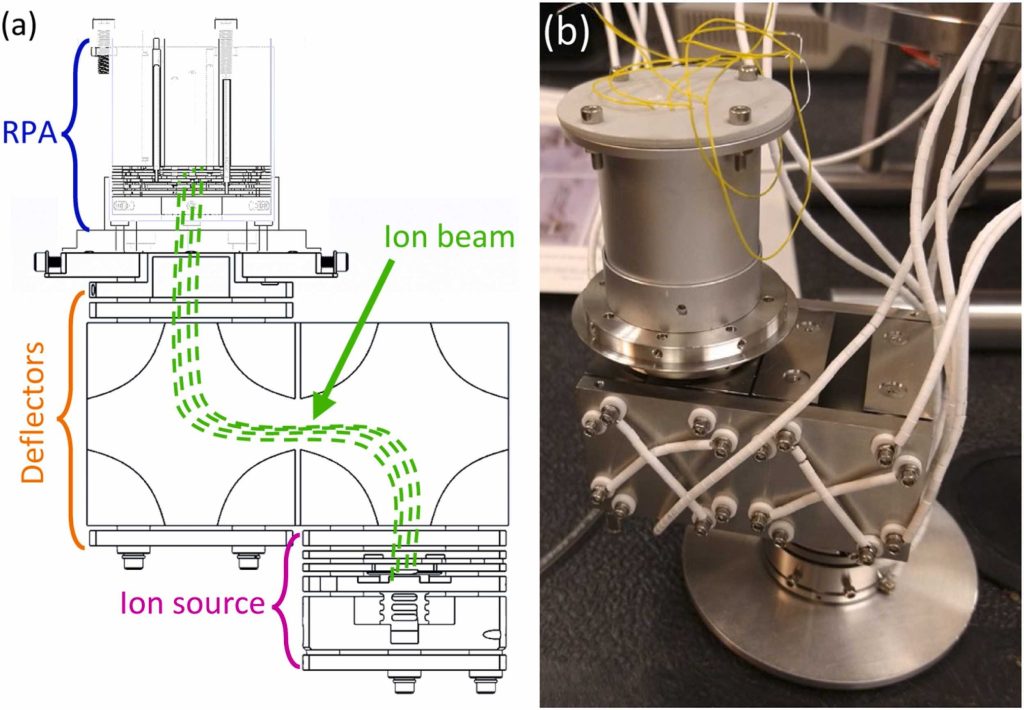

When it comes to monitoring changing weather patterns in LEO, retarding potential analyzers (RPAs) are a vital piece of equipment. First deployed in a space mission in 1959, these multi-electrode instruments essentially detect the energy in the ions that float in the plasma molecules present in the Earth’s upper atmosphere. Also applied as in-orbit mass spectrometers, the versatile sensors are capable of measuring energy and analyzing chemicals to inform weather predictions.

RPAs themselves work by using a series of electrically-charged meshes with tiny holes to strip electrons and other particles away from ions, which in turn, create a current that can be measured and analyzed. According to the MIT team, making such devices effective depends on ensuring their housing structure and meshes align, as well as their insularity and ability to withstand drastic temperature swings.

However, the scientists also point out that current plasma sensors tend to be made from silicon in cleanroom conditions, via a process that requires weeks of intricate fabrication. As such, RPAs can be very expensive, limiting their potential to be fitted to the CubeSats that are increasingly making LEO-based R&D more accessible. With this in mind, the MIT team have developed a means of 3D printing them from glass-ceramic instead, that could help advance in-situ ionospheric studies.

“If you want to innovate, you need to be able to fail and afford the risk. Additive manufacturing is a very different way to make space hardware,” explains Velásquez-García. “I can make space hardware and if it fails, it doesn’t matter because I can make a new version very quickly and inexpensively, and really iterate on the design. It is an ideal sandbox for researchers.”

“When you make this sensor in the cleanroom, you don’t have the same degree of freedom to define materials and structures and how they interact together. What made this possible is the latest developments in additive manufacturing.”

Introducing a 3D printed ‘RPA’ sensor

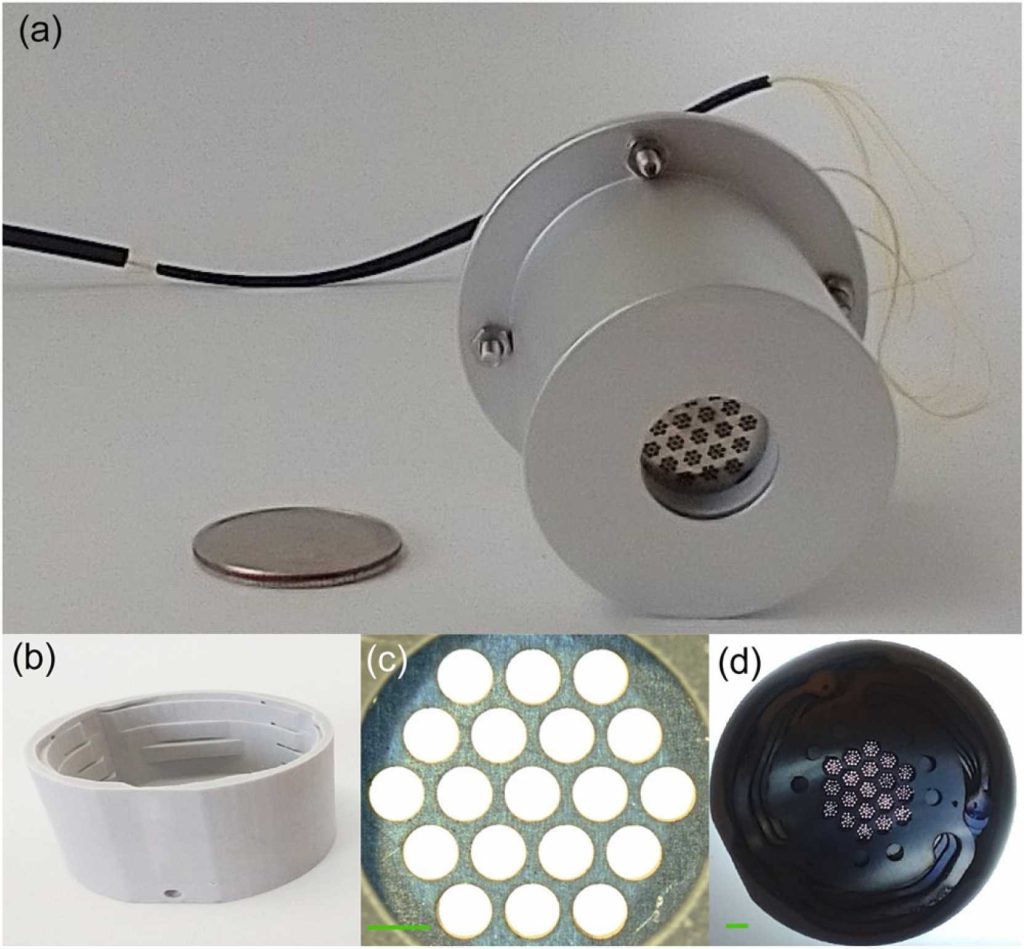

At the core of the team’s redesigned sensor is a laser-cut, five-electrode stack, inside a 3D printed glass-ceramic electrode housing and CNC-machined shroud. In practice, the housing is designed to spatially distribute electrodes using a set of grooves that interact with a set of deflection springs. That said, the researchers actually explored two different stack designs, one in which all apertures were the same size, and another, where clusters were matched to a single aperture in a ‘floating grid’ formation.

Both were made using a Tethon 3D Bison 1000 system and Vitrolite, a durable pigmented glass capable of withstanding temperatures of up to 800°C, and designed with hexagonally-packed apertures, to maximize the number that could be fitted in. For each RPA design, the aperture size was also optimized via finite element analyses, in an attempt to achieve optimal ion transmission across the device’s grid.

Once ready, the team subjected their prototypes to ion energy distribution simulations and practical testing via electron impact ionizer and helicon plasma testing. In the former, both designs proved able to accurately estimate the average energy of ions, but in practical evaluations the devices showed potential in different application areas.

In practice, the uniform grid design was especially effective at measuring a wide range of plasmas, similar to those that a satellite would ordinarily encounter in orbit. However, the other, featuring a floating grid alignment, proved better-suited to sensing dense and cold plasmas, at an accuracy of just 50 µm, the likes of which are usually only measurable using ultra-precise semiconductor devices.

Given that testing had revealed their devices could “perform on par with the state of the art,” the researchers concluded them to have significant potential as a means of facilitating accessible weather monitoring. Moving forwards, the team even believe that binder jet 3D printing could be used to produce even more of the RPA’s parts, in a way that could reduce its mass and improve its performance.

Entering an era of 3D printed CubeSats

Additive manufacturing continues to find widespread satellite applications, not just in the creation of ancillaries, but of the casings of the devices themselves. ROBOZE, for instance, has partnered with the University of Colorado Boulder to 3D print a weather-monitoring CubeSat designed to analyze the electromagnetic waves caused by lightning strikes.

Alongside Alba Orbital and Mini-Cubes, CRP Technology has also continually used its Windform XT 2.0 material to 3D print pocket satellites and deployers. Working with the former, the firm previously deployed the technology and its carbon fiber composite to reduce the weight of the ‘Alba 2’ PocketQube deployers by 60%.

On a more commercial level, Franco-Italian aerospace manufacturer Thales Alenia Space continues to use 3D printing in the series production of satellites. In fact, just last month, the firm announced plans to work with start-up MIPRONS to develop a novel 3D printed water-fuelled satellite thruster with enhanced maneuverability.

The researchers’ findings are detailed in their paper titled “Compact Retarding Potential Analyzers Enabled by Glass-Ceramic Vat Polymerization for CubeSat and Laboratory Plasma Diagnostics,” which was co-authored by Javier Izquierdo-Reyes, Zoey Bigelow, Nicholas K. Lubinsky and Luis Fernando Velásquez-García.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the researchers’ 3D printed plasma sensor. Photos via MIT.