The Canadian Space Agency (CSA) has turned to AON3D’s 3D printing solutions to develop biomedical R&D equipment in time for its launch to the International Space Station (ISS).

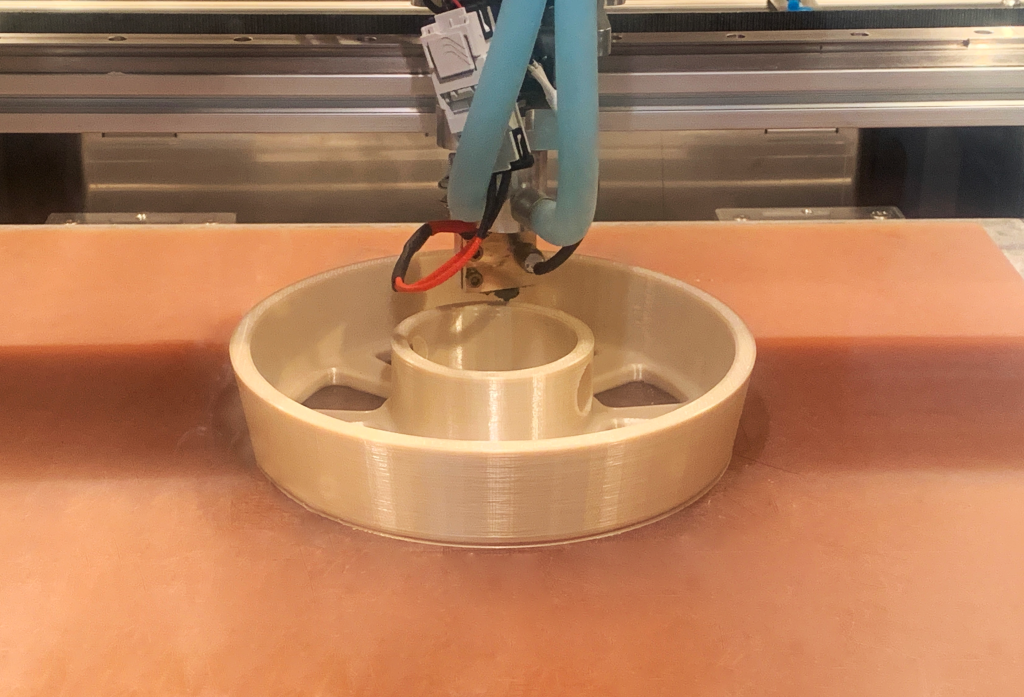

Specifically, the CSA has adopted the AON3D M2+ 3D printer to produce the centrifuges needed for blood sample preparation as part of ISS research into the impact of living in space on the human body. Adopting the system is said to have enabled the agency to reduce the part’s lead time from weeks down to just 16 hours while facilitating design iteration by drastically simplifying its production.

IDEX 3D printing with AON3D

Launched in June 2021, the AON M2+ is Montreal-based Fused Filament Fabrication (FFF) 3D printer manufacturer AON3D’s flagship system. The machine features an independent dual extrusion (IDEX) architecture, meaning that the unit’s printheads share the same Y-axis but move independently on the X-axis. In practice, this allows the 3D printer to produce two parts at once, effectively doubling its throughput.

At 450 x 450 x 640mm, the AON M2+ also sports one of the industry’s largest sub-$100,000 actively-heated build chambers and a maximum nozzle temperature of 500°C. As a result, the open-material machine is compatible with hundreds of high-performance filaments, including those with higher strength-to-weight ratios than aluminum, ESD-safe thermoplastics, and biocompatible polymers.

Since the machine’s release, AON3D has pledged to continue supporting users with an AON M2+ 3D printer firmware update and three new materials. Set to launch later this year, the upgrade will bring mirror and duplication mode capabilities to the system. The firm’s material launch, meanwhile, has seen it add Zymergen Z2 Polyimide, VICTREX AM 200 LMPAEK, and Braskem FL900PP-CF compatibility.

Due to its high-temperature 3D printing capabilities, the AON M2+ has previously been adopted by the likes of Astrobotic within aerospace applications. Using AON3D’s technology, the firm has developed 3D printed Peregrine Lander parts from materials that prevent ‘outgassing,’ or the build-up of condensation in the cold vacuum of space, an issue that can lead to component weakness and failure.

Facilitating biomedical R&D in-orbit

Having been tasked with producing a flight-ready centrifuge for the ISS, the CSA’s engineers initially considered manufacturing it via traditional technologies. However, the team quickly realized that developing the part using CNC machining or injection molding would bring lofty prototyping costs and extend its lead time beyond its launch window.

Another aspect the engineers had to consider was NASA’s outgassing standards. To remain compliant with these safety specifications, something the CSA labeled a ‘primary design consideration,’ material compatibility was critical. As such, the agency didn’t consider traditional technologies to be up to the task and turned to the M2+ system and Stratasys’ ULTEM 9085 resin instead.

In particular, the latter was chosen due to its flame retardancy, non-toxicity, and low Total Mass Loss (TML) when used in a vacuum, which enabled it to meet NASA’s stringent specifications. Once the CSA had identified the ideal machinery for the job, it was then deployed to create a centrifuge for blood fractionation on the ISS, i.e., its separation into red or white cells, platelets, and plasma.

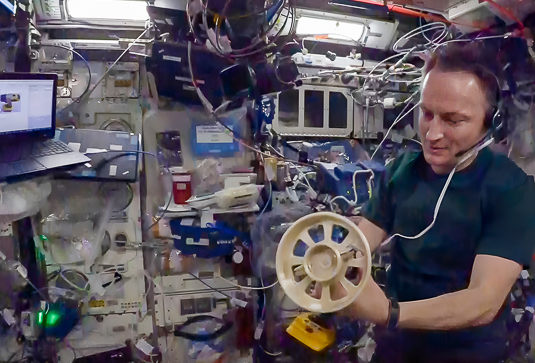

Leveraging the part, ISS scientists have now begun experimenting with astronauts’ blood samples to develop diagnostic information on the impact of long-term exposure to Low Earth Orbit (LEO) conditions. The project’s success is also said to have inspired other 3D printing programs onboard the station, including the NSERC-backed ‘PEEKbot project.’ The initiative will reportedly see the R&D of a rover capable of withstanding the lunar night, which can get as cold as -250° C.

Advancing 3D printing on the ISS

The ISS has become something of a hub for advanced 3D printing research in recent years, with the facility playing host to various zero-gravity R&D projects. In August last year, a Redwire lunar regolith 3D printing study was unveiled, which has seen the firm assess the technology’s Moonbase-building potential onboard the ISS.

In the past, the station’s facilities have also benefited from upgrades developed using additive manufacturing. February 2020, for example, saw the ISS 3D bioprinting facility fitted with ceramic manifolds, which were 3D printed by Lithoz and Techshot, and designed to improve the number of usable tissues grown inside its onboard bioreactors.

Likewise, Italy’s National Institute for Nuclear physics (INFN) has previously used Stratasys’ technologies to develop the 3D printed Mini-EUSO telescope. Now featuring a 3D printed mechanical structure, the device is being used to analyze UV emissions from the ISS and help scientists better understand cosmic rays.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows AON3D’s 3D printed centrifuge onboard the ISS. Photo via AON3D.