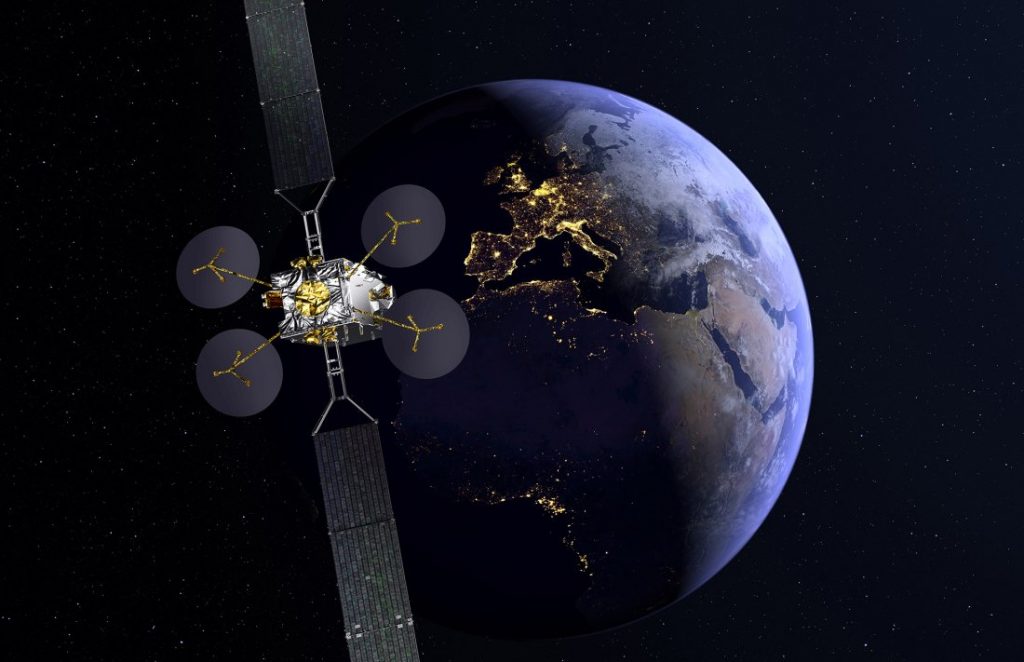

Aerospace manufacturer Thales Alenia Space has teamed up with Italian start-up MIPRONS to develop a new water-fuelled satellite propulsion system.

Set to be built using a combination of MIPRONS’ proprietary technology and 3D printing, the tiny, eco-friendly thruster is designed to only use water as a propellant. As such, once ready, the system is expected to enable the faster, cleaner maneuvering of satellites, while being small and scalable enough to launch devices of varying shapes and sizes.

“This agreement confirms Thales Alenia Space’s strategy to play a pivotal role in new space initiatives, reflected in synergies generated with exciting new start-ups that catalyze the entire space ecosystem,” said Massimo Claudio Comparini, SVP of Observation, Exploration and Navigation at Thales Alenia Space. “We are always willing to tackle new challenges that emphasize the growing strategic importance of the space sector.”

“We are very proud to team up with MIPRONS, which is gaining increasing international recognition, since our collaboration could well change the paradigm for space missions.”

Multinational aerospace collaboration

Essentially a joint venture, owned 67% by French Multinational Thales and 33% by Italian defense contractor Leonardo, Thales Alenia Space markets defense, travel and aerospace manufacturing services to commercial and state-level entities alike. With FY 2021 revenue of €2.15 billion, 8,900 employees and a presence in ten countries, the firm has also established itself as Europe’s largest satellite builder.

In its push for satellite manufacturing supremacy, the business has often turned to 3D printing. Since partnering with Poly-Shape SAS to develop what was then the largest-ever metal 3D printed satellite part in 2016, Thales Alenia Space has fired hundreds of polymer 3D printed tubes into space, and used the technology to support the launches of the Telkom 3S, SGDC and KOREASAT-7 satellites.

More recently, the company has begun utilizing 3D printing in series satellite production, by integrating the technology into its Spacebus NEO platform production process. The first run of these additively manufactured components was developed as part of a project with Eutelsat Communications. But the firm continues to innovate with the technology, reportedly partnering with 3D Systems last year to 3D print upgraded mechanisms for controlling the satellite’s steering.

MIPRONS’ satellite-thrusting plans

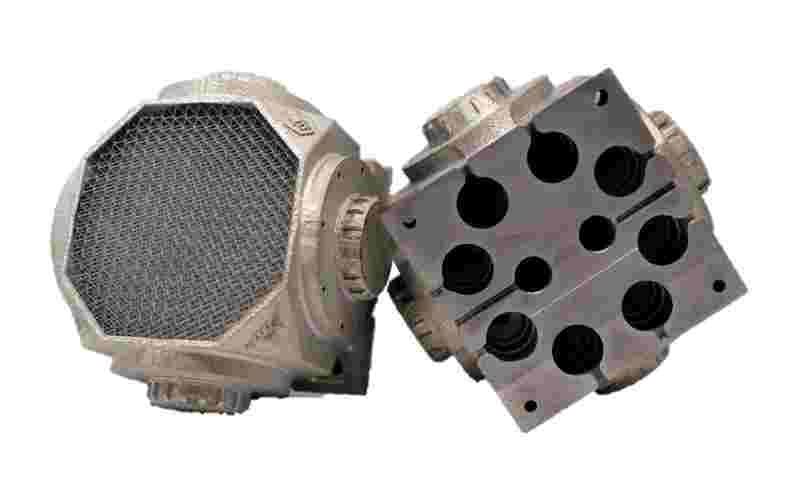

Based in the town of Colleferro, MIPRONS has spent the last three years developing propulsion systems for microsatellites. In that time, the firm has sought to come up with the tiniest, most powerful and versatile propulsion system possible, and so far its efforts have yielded two satellite-thrusting solutions: ALEXIUS and ALBIREO.

Despite being less than a third of the size of a nanosatellite, the company’s inaugural ALEXIUS device is capable of delivering up to 20N of thrust at a specific impulse for more than 350 seconds. The thruster is therefore small and powerful enough to allow tiny satellites to rapidly carry out high-thrust maneuvers, as part of commercial, scientific, intelligence, defense or security missions.

MIPRONS’ follow-up, the ALBIREO, is essentially being developed as an ALEXIUS upgrade that lowers its weight, while enabling it to facilitate low and high-thrust maneuvers in a single system. The former remains at the lab-testing stage, but the firm aims to have it flight-ready by Q4 2023, and both are said to be enabled by a ‘proprietary technology’ it has developed.

While many existing satellites are propelled by chemical thrusters, in which a fuel tends to be burned as a means of providing thrust, electric thrusters are increasingly gaining traction as a lower mass, more efficient means of propulsion.

In a similar vein, the company has now announced its own plans, to build on its technology, and develop a new system that uses electrolysis to break down water into hydrogen and oxygen, before feeding them into a combustion chamber. The thruster is reportedly set to feature several 3D printed components, with MIPRONS leading its R&D, and Thales Alenia Space supporting its environmental testing.

When flight-ready, the system is expected to facilitate the orbit-raising, de-orbiting and collision avoidance of satellites. Following the project’s unveiling, MIPRONS CEO Angelo Minotti said that even though the program is still in its early stages, it was “a privilege to earn the trust of one of the world’s largest space companies.” As such, the firm aims to have the system operational “as soon as possible.”

MIPRONS is one of many aerospace firms currently experimenting with using 3D printing to produce more efficient satellite propulsion systems. In April 2022, for instance, it was announced that Aerojet Rocketdyne’s 3D printed quad thruster had been optimized, in a way that could unlock faster, lower-cost and more sustainable lunar exploration.

Back in 2021, researchers at the Massachusetts Institute of Technology (MIT) also revealed that they’d designed and tested a 3D printed ion-powered satellite thruster. Believed at the time to be the first fully-printed device of its kind, the tiny propulsion system fires charged ionic particles from its outer shell, giving it a few micronewtons of propulsion.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows some of the tiny combustion chambers incorporated into MIPRON’s existing satellite thruster. Photo via MIPRON.