ScanLAB, a German manufacturer of scanning equipment, is set to release a new metal additive manufacturing scan head, the fiberSYS, at Formnext 2019 in Frankfurt from November 19-22.

This scan head is designed as an all-in-one system to efficiently optimize laser systems and machine building systems. The company states, “The 3D printing sector has been utilizing multi-head machines for many years. Productivity for large-area workpieces, in particular, can be significantly enhanced by combining multiple scan systems with high-overlap image fields.”

“The new system was developed with this key relationship in mind. Its exterior dimensions and beam exit location are optimized to facilitate maximum overlap between adjacent scanners.”

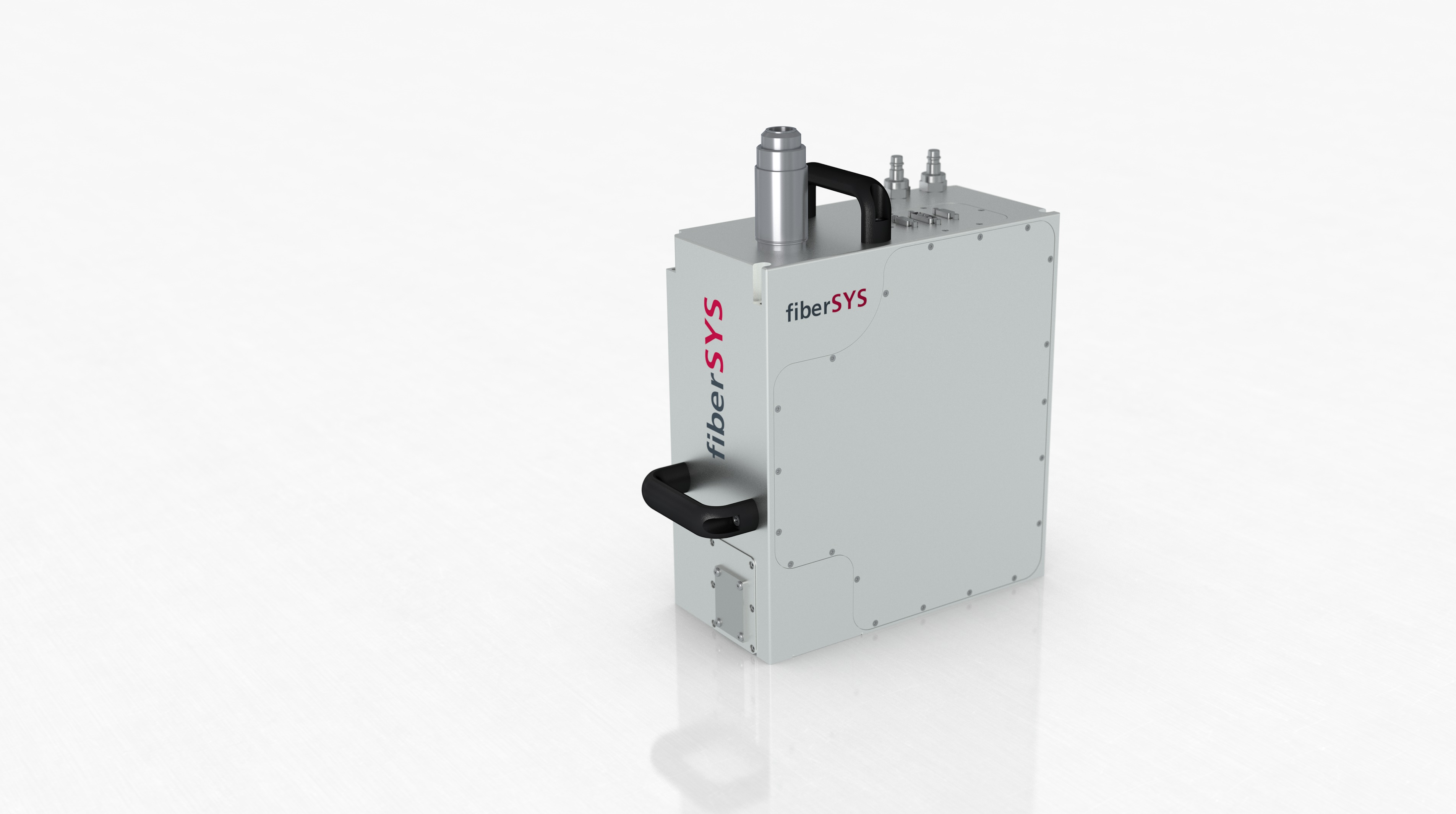

The ScanLAB fiberSYS

ScanLAB has over 25 years of experience in laser beam positioning for additive manufacturing. Earlier this year, the company expanded its range of entry-level scan heads with the basiCube 14. As its latest scanning system, the modular fiberSYS aims to simplify machine construction as it eliminates optomechanical design complexities.

It is configured for control via an RTC board and features a fiber adapter for the direct connection of a laser, as well as a process monitoring interface. The system is said to deliver exceptional imaging quality and high dynamic performance due to the pre-focus configuration.

As stated by Scan LAB, machine builders can now concentrate completely on laser processes, without other tool burdens. The fiberSYS will be available in Q2

2020 with design recommendations.

Laser beam and positioning systems

In June 2019, ScanLAB introduced a new product in its excelliSCAN line, known as the excelliSCAN 20 scan system. This utilizes an RTC6 PCI Express control board and has a 14 mm aperture for improved accuracy in micromachining and 3D printing.

Upon its release, Georg Hofner, CEO of SCANLAB, said, “With the excelliSCAN 20, we’re serving demand from customers who want to break through their previous processing limitations. Initial application tests have been very promising.”

Formnext visitors can find ScanLAB’s latest solutions at hall 12.0, booth B41.

For the latest news about additive manufacturing, subscribe to our 3D printing newsletter and join us on Facebook and Twitter. We also have jobs in the industry, visit our 3D Printing Jobs page to learn more.

Featured image shows the fiberSYS additive manufacturing scan head. Photo via ScanLAB.