Voting shortlists for the 2021 3D Printing Industry Awards are now open. Who do you think should receive top honors this year? Have your say now.

The battery 3D printing specialist Sakuu Corporation has announced the closure of a follow-on financing round that takes its total capital raised to $62 million.

Using its newfound investment, the company aims to fund the launch of its first-gen solid-state batteries (SSBs) in H2 2022, as well as the future release of its second iteration battery 3D printer. With twice the energy density and 30% less weight than existing Li-Ion cells, the firm’s second-gen batteries have potential residential and industrial applications, within energy storage, microreactors and electronics.

“I am incredibly grateful for our investor’s continued support,” said Robert Bagheri, CEO of the Sakuu Corporation. “This funding will allow us to execute on our key objectives: commercializing the world’s first true multi-material, multi-process additive manufacturing platform, expanding our R&D team and continuing to develop advanced materials and groundbreaking active devices.”

Battery 3D printing with Sakuu

Formerly known as KeraCel, Sakuu is a Musashi Seimitsu-backed manufacturer of SSBs that has consistently touted the electric vehicle (EV) applications of its technologies. After rebranding earlier this year, the company unveiled its Sakuu AM Platform, a multi-material system that’s able to combine binder jet and powder bed 3D printing, to process multiple ceramics and metals within the same part layer.

In doing so, the 3D printer is said to yield storage devices with improved interfacing and stronger ceramic layers than existing batteries, while incorporating monolithically-layered cells that are far easier to produce at scale.

Since announcing the ‘Alpha’ version of its 3D printer in May 2021, Sakuu has gained three new patents that could allow it to further improve the efficiency and flexibility of its SSB production process. These include a novel hybrid solid-state design with the potential to result in faster-charging cells, and an electrography-based 3D printer capable of ramping up the speed and precision of their manufacture.

The firm has also begun building a pilot battery 3D printing facility to exhibit the viability of its technologies, and use them to create samples for its Early Access partners. Once completed later in 2021, the complex is initially set to produce up to 2.5 MWh of SSBs per annum, with manufacturing to be expanded in 2022 via a fleet of Sakuu AM Platforms, which will produce up to 1 GWh of capacity each year.

Bringing ‘SSBs’ to market

Following the closure of its financing round, Sakuu has stated that it remains “on-track to transform the world of active device manufacturing” with its AM Platform. Over the past year, the company says it has raised the energy density of its first-gen battery from 40Wh/l to 600Wh/l, its cell count from 1 to 30, and its capacity from 2.3mAh to 3000mAh, making it “very competitive with current Li-Ion batteries.”

Sakuu has also 3D printed a marketable version of its first-gen battery as well as a demonstrator of its second iteration ‘ASSB,’ which it expects to accelerate the adoption of SSBs within EVs and elsewhere, when put into full production by 2023.

At its pilot facility, meanwhile, the firm has worked with Honeywell and Relevant Industries to develop first-gen samples, and ship them to undisclosed ‘key partners.’ Not only has this allowed it to secure ‘volume SSB commitments’ from EV and mobility clients, but Sakuu says that it’s now in a position to commercialize in a way that “leapfrogs competitive technologies,” and puts it “well ahead of its peers.”

“We are expanding our operations to support our pilot lines, and in preparation for the commercial launch of the Sakuu 1000 AM platform, which will enable our customers to unlock breakthrough products and achieve industry-leading performance metrics across multiple parameters,” added Bagheri.

“With the additional funding, we are excited to continue developing our AM platform in support of our strategic customers and early access partners.”

Juiced-up 3D printed cells

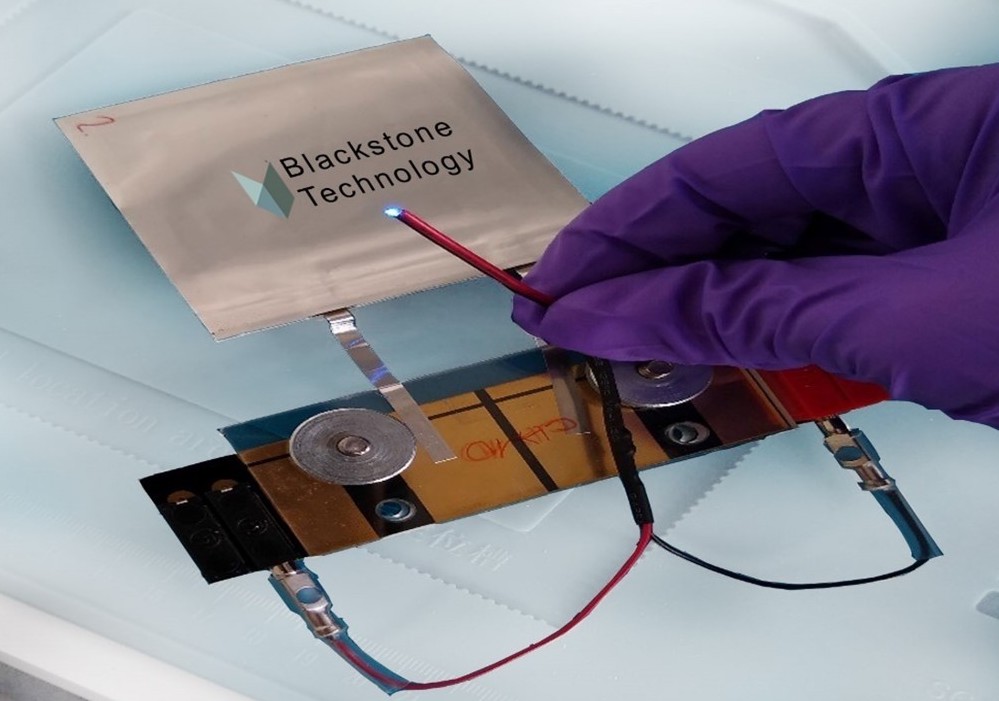

Although battery 3D printing largely remains an emerging technology, its development and commercialization have come on leaps and bounds over the last year. Back in June 2021, Blackstone Resources, whose subsidiary is said to be developing a means of 3D printing Li-Ion batteries, announced it was considering listing on the U.S. stock exchange.

UK-based 3D printer manufacturer Photocentric has also established a dedicated battery R&D division, in which it’s designing its own energy-efficient storage devices. By 3D printing electrodes that are smaller, lighter and better-suited to automotive applications, the firm reportedly aims to develop economical fuel cells for Tesla’s upcoming Giga plant.

Similarly, in the academic space, researchers at the California Institute of Technology (Caltech) have developed a method of DLP 3D printing Li-Ion electrodes that demonstrate enhanced battery performance. Using their novel technique, the team have been able to create complex polymeric structures that function as both stable anodes and cathodes.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the inside of Sakuu’s AM Platform. Photo via Sakuu.