The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

6K Additive, a producer of industrial materials for the 3D printing sector, has bolstered its metal alloy portfolio with the acquisition of Specialty Metallurgical Products (SMP).

SMP specializes in titanium and zirconium tablets that are used as a grain refinery for the metal alloys market, which will expand 6K Additive’s metal alloy product portfolio for the aerospace, automotive, and medical industries.

“We have over 20 years of experience supplying our Ty-Gem grain refining products to the aluminum industry,” said Frank Roberts, President of 6K Additive. “Adding SMP’s titanium products to our portfolio will complement our existing offering while enhancing our expertise in the process.

“The acquisition will also add an entire new product line to our current portfolio in zirconium tablets.”

6K’s growth trajectory

6K has made several recent announcements regarding funding, facility expansions and new product launches. Just last month, the firm raised $51 million in a Series C financing round that will facilitate the completion of its Battery Development Center of Excellence, double its 6K Energy team, and triple its production capacity for 3D printing metal powders.

The company also announced the commercial launch of a new set of refractory metal powders for 3D printing, including high-value metals such as tungsten, rhenium, and niobium-based alloys. 6K hopes to target the defense, aerospace, and medical sectors with the new range, due to their requirements for materials to handle high-temperature and high-strength applications.

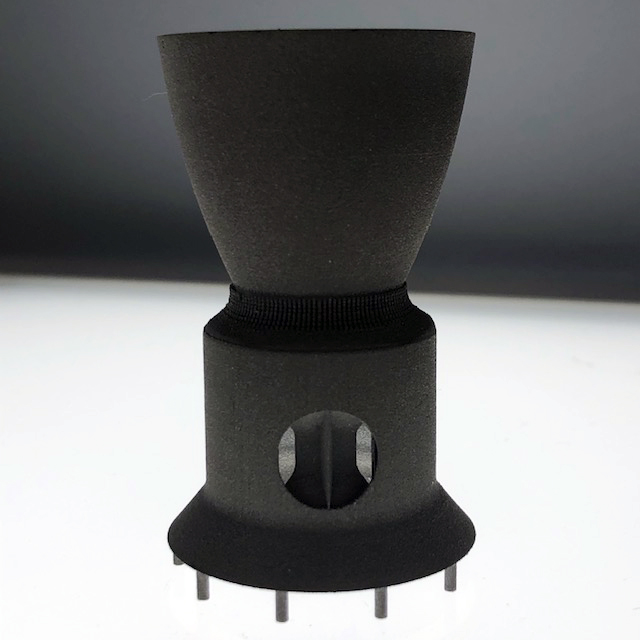

The firm’s patented UniMelt system is based on a microwave plasma process that converts recycled feedstock such as millings and turnings into 3D printable metal powders. The process reportedly delivers an improved level of sustainability over methods such as gas and plasma atomization regarding efficiency and cost.

Bringing SMP onboard

Based in Red Lion, Pennsylvania, SMP is reportedly the first company to produce and offer a 100 percent titanium tablet to aluminum alloy producers which was free from binders and salts. According to SMP, today nearly all aluminum smelters use 100 percent titanium tablets or pucks to make their alloys.

In addition to titanium tablets, the company also specializes in zirconium tablets, with both widely used as a grain refinery within the metal alloys market.

“We have a long history of supplying the top end of titanium additives to the industry and have established SMP as the leading supplier of zirconium,” said Jim Clark, Former President of SMP and now a Strategic Advisor of 6K Additive. “Becoming part of the 6K Additive team ensures our customers are provided with the same quality product, but backed by a larger organization that has the logistics and operational infrastructure to support our rapid growth.”

While the full terms of the acquisition have not been disclosed, the deal will see SMP’s products elevate 6K Additive’s existing line of Ty-Gem compacts used in similar applications and markets. The new products will enable the company to expand its commercial relationships into new and existing companies for titanium customers, while also facilitating the development of new applications and customers for zirconium.

According to 6K Additive, the move will further strengthen its position as a leading supplier of metal alloying additives to both primary and secondary aluminum producers across the globe. The deal also expands the firm’s product portfolio for metal alloys for the aerospace, automotive and medical industries.

“The quality products SMP brings to 6K Additive enables us to go broader and deeper with our customers providing a quality, sustainable alloying solution no other company in the world can offer,” added Roberts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows 6K’s Battery Center of Excellence in North Andover, MA. Photo via 6K.