The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Sakuu Corporation (formerly KeraCel), a specialist in 3D printed energy storage devices, has commenced the construction of a new pilot facility for the production of 3D printed solid-state batteries.

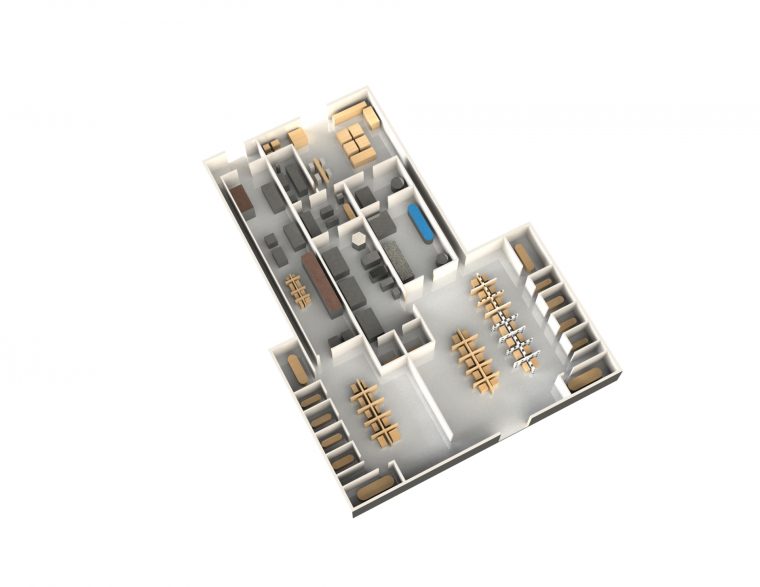

Expected to complete by the end of 2021, the pilot line will reportedly be able to produce up to 2.5 MWh of solid-state batteries every year. In future years, it will also be purposed as a customer learning center for the company’s multi-material 3D printing system, the ‘Sakuu AM Platform’. Engineering firms Relevant Industrial and Honeywell will aid in the establishment of the facility by providing engineering, process design, and systems integration support.

John Carte, CEO of Relevant Industrial, said, “Relevant is excited to be part of this groundbreaking project. Combining Sakuú’s advanced technology with our experience in engineering, design, and systems integration using Honeywell’s leading automation technologies provides a unique opportunity to shape the future of manufacturing. We appreciate Sakuú’s confidence in Relevant and look forward to a long and mutually beneficial partnership.”

Towards 3D printed solid-state batteries with Sakuu

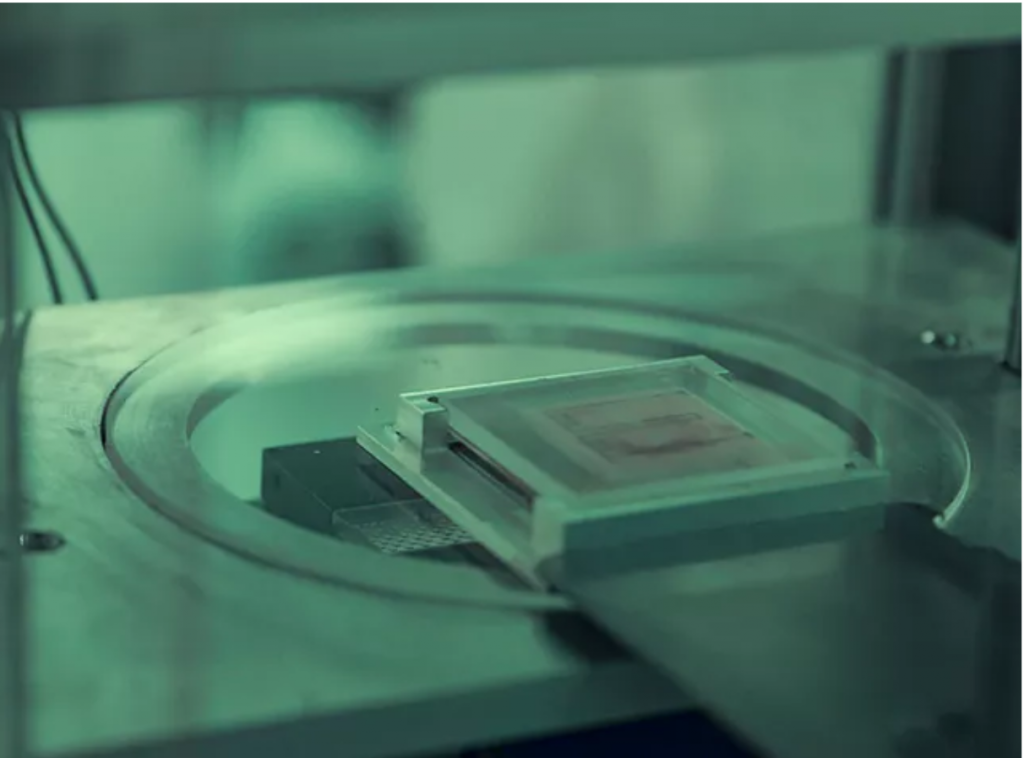

Since rebranding from KeraCel earlier this year, Sakuu has placed its focus on 3D printing solid-state batteries for applications such as electric vehicles. The company’s recently developed Sakuu AM Platform combines powder bed technologies with material jetting and is compatible with ceramics, metals, and the company’s own ‘Poralyte’ support material. According to the firm, the 3D printing technology is able to yield solid-state batteries with half the size and twice the capacity of traditional lithium-ion cells, all while being “much less” costly at high volumes.

Sakuu was also recently granted three new patents, each of which is intended to improve the efficiency and flexibility of the company’s multi-material additive manufacturing capabilities.

The pilot solid-state battery facility

The upcoming pilot line is set to demonstrate the viability of Sakuu’s battery production process while enabling the company to deliver sample battery products to its Early Access partners. Both Relevant and Honeywell will help in scaling Sakuu’s historically lab-based technology into a full-fledged manufacturing facility.

In 2022, the project will then move onto its second phase, where a fleet of Sakuu AM Platforms will be used to 3D print solid-state batteries totaling up to 1 GWh of capacity a year.

Robert Bagheri, CEO, and Founder of Sakuu Corporation adds, “This is an important milestone for Sakuú. Our SSB technology development has progressed to the level where we have decided to move ahead with our plan to construct and operate a pilot facility. With the assistance of our key development partners, Relevant Industrial and Honeywell Process Solutions, the facility will be operational by end of 2021. This facility will enable us to provide our strategic customers and early access partners with solid-state batteries for their own development and testing.”

The 3D printing of energy storage devices is still very much a niche field. Earlier this summer, Swiss mining and investment company Blackstone Resources announced that it was considering listing its Blackstone Technology division on the U.S. stock exchange. While details about the operations of its subsidiary are scarce, the firm says that it’s developing a 3D printing technology that’s capable of producing high-energy-density lithium-ion batteries.

Elsewhere, in the academic space, researchers from the California Institute of Technology (Caltech) recently developed a novel method of 3D printing electrodes for lithium-ion batteries. Using DLP 3D printing technology, a visible light-based form of vat photopolymerization, the researchers were able to fabricate complex polymer structures before converting them into useful electrode materials via a thermal post-processing treatment.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a rendering of Sakuu’s upcoming pilot line. Image via Sakuu Corporation.