The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Scientists at the South China University of Technology and University of Warwick have developed novel fruit labels that are capable of keeping fresh produce edible for longer.

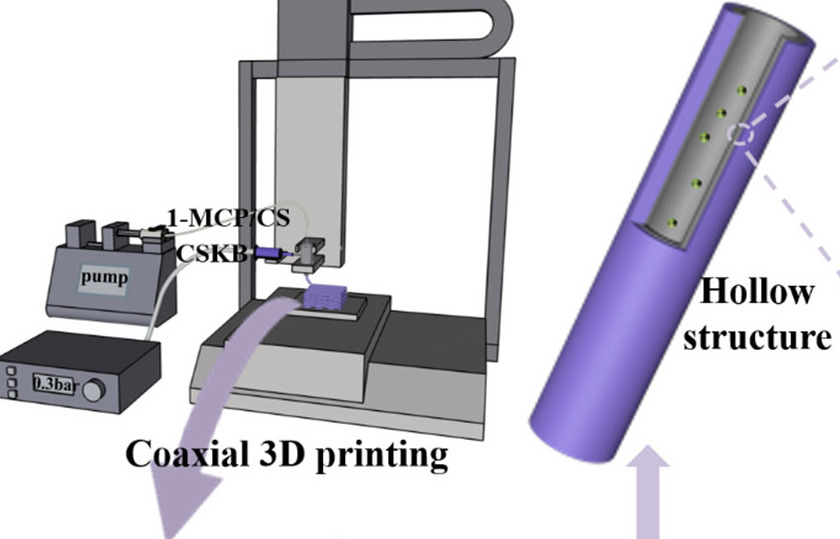

Produced via coaxial 3D printing, the team’s tags feature cellulose nanofibers loaded with shellfish extracts and growth regulators, which can be pre-programmed to release steadily into the pores of fresh foods.

When used to treat lychees, the researchers say that their labels not only extended the shelf-life of the fruit, but allowed them to monitor its freshness with precision, making the devices a promising basis for the “intelligent packaging” of the future.

“[Our] cellulose nanofiber (CNF)-based labels with dual functions of fruit freshness keeping and visual monitoring, prolonged the shelf life of lychees for six days.” said the researchers in their paper. “The CNF-integrated labels developed in this work, provide a new idea for the development of ‘intelligent food packaging.’”

Real-time food monitoring

Due to growing challenges like global warming, COVID-induced shipping disruption and Brexit-related red tape, it’s never been more important to keep produce fresh for the long haul. To meet this demand, as well as rising consumer food standards, so-called ‘intelligent packaging systems,’ are therefore increasingly being used to track the condition and quality of packaged food and prevent it from going off.

Largely, such smart wrappers monitor any changes in pH within produce containers using chemically-sensitive dyes, such as anthocyanins, which change color to indicate that fruit is beginning to degrade. However, these natural water-soluble pigments are only capable of monitoring freshness, and they aren’t able to make fruits or vegetables last any longer.

To get around this, the researchers say that the synthetic plant growth regulator ‘1-MCP’ can be paired with organic dyes like the shellfish-extract chitosan, to delay produce from ripening. In its normal form though, 1-MCP is too volatile for mixing, thus the team has decided to 3D print a ‘core shell structure,’ capable of releasing chitosan in a controlled way and preventing foods from spoiling early.

3D printing “intelligent packaging”

Before they began 3D printing their CNF-based labels, the scientists first integrated sodium alginate (SA) and κ-carrageenan (KC) matrix materials into their bio-ink, which would allow it to be processed without compromising on food safety, as well as a pH-sensitive blueberry anthocyanin, due to its distinctive color, that could later be used to monitor freshness.

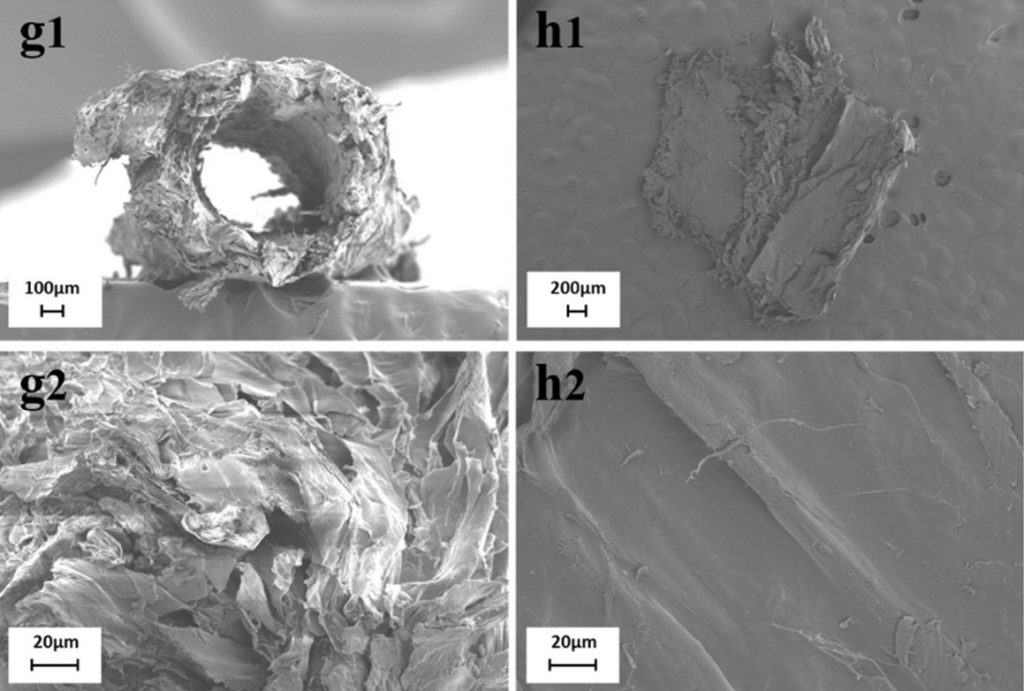

Once ready, the team’s formula was then loaded into a Y&D 7300N coaxial 3D printer and deposited into layers, before being spray-cured and freeze-dried to form hollow fibers. In theory, these nanotubes would be able to balance the electrostatic effect of chitosan against the device’s CNF shell, allowing them to ‘trap’ 1-MCP and release it on-demand.

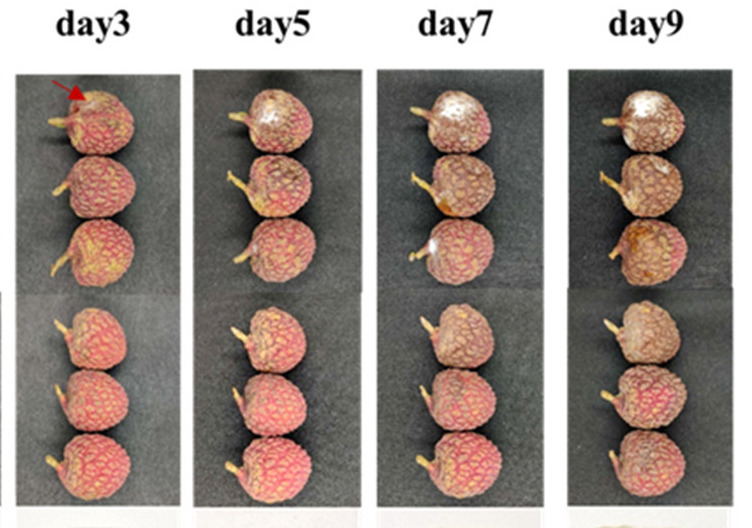

Putting this idea to the test, the team eventually applied their labels to lychees, managing to prevent mildew spots from appearing on them until nine days after picking, and making them last six days longer overall. During testing, the packaging also gradually changed color from purple to pink, making the fruit’s spoilage much easier to spot with the naked eye.

Even though these evaluations were carried out at room temperature, when such fruits would normally be refrigerated, and the team didn’t factor in the impact of fish allergies on their devices’ application, they did find that their labels functioned as expected in controlled settings, thus they now intend to apply them to other fruits and vegetables in future.

“Results proved the high sensitivity and accuracy of the label’s freshness visual monitoring [capabilities],” concluded the team in their paper. “Our label addresses the shortcomings of single-function packaging systems, [by] employing coaxial 3D printing to construct integrated devices, with both fruit freshness keeping and monitoring functions.”

AM advances in food safety

Thanks to 3D printing’s inherent precision and flexibility, the technology has often been utilized to create food safety sensors, capable of ensuring that both produce and livestock remain safe to eat after shipping. Just last year, U.S. researchers deployed Optomec’s Aerosol Jet Printing (AJP) technology to create novel graphene food-testing electrochemical sensors.

Similarly, researchers at Nanyang Technological University, University of Chemistry and Technology Prague and King Saud University, have 3D printed mycotoxin-detecting electrodes. If deployed in practise, the team believe that their devices could pave the way for a new method of keeping products in food storage safe to eat until they reach the shelf.

In Switzerland, meanwhile, scientists at EMPA have taken a completely different approach to food monitoring, by developing a 3D printed fruit simulator. Designed to mimic the shape and texture of organic produce, the team’s apple substitute is said to be capable of tracking freight temperatures, and ensuring that food arrives at peak ripeness for customers.

The researchers’ findings are detailed in their paper titled “3D printed nanocellulose-based label for fruit freshness keeping and visual monitoring,” which was co-authored by Wei Zhou, Zhengguo Wu, Fengwei Xie, Shuwei Tang, Jiawei Fang and Xiaoying Wang.

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the coaxial 3D printing process behind the researchers’ fruit freshness labels. Image via the Carbohydrate Polymers Journal.