Russian space corporation Roscosmos has confirmed plans to support long-term lunar missions by 3D printing structures made from on-site material. Seemingly the best option for such directives, the declaration adds to plans made by NASA and the European Space Agency (ESA) that also intend to use Lunar or Martian regolith as source material for 3D printers on the Moon and Mars.

Currently, according to Roscosmos Chief Dmitry Rogozin, Russian cosmonauts will land on the Moon for the first time in 2030. By that time, the corporation should also be expected to share company with NASA which is currently targeting a Moon landing by 2024 as part of its Moon to Mars approach. Numerous 3D printing technologies are expected to help the administration achieve this goal.

3D printing to Mars

Practically every business in space exploration currently has its sights set on Mars. Doing so will extend humanity’s physical reach into the solar system further than ever before, furthering our search for life beyond plant Earth and potentially adding to our understanding of how it all started billions of years ago. To get there, and to stay there for extended periods of research, the parties involved in the exploration will however need a more substantial infrastructure than they have now.

One of the first steps in this plan if for humans to return to the Moon. Here, parties intend to build a base that will then facilitate travel to further afield, i.e. Mars and beyond.

3D printing has great potential in in-space construction as it facilitates the fabrication of virtually anything using limited feedstock, locally-sourced materials, or even waste. The first experimentation of the technology in space has been done through Made In Space’s Additive Manufacturing Facility (AMF) aboard the International Space Station (ISS). As partners of the ISS Roscosmos, alongside NASA, ESA, JAXA, and CSA, will share in the knowledge gained from AMF experimentation. At present, it has only been used to make small tools using plastic that was part of a payload. More development has since been undertaken to expand 3D printing to other materials, including high performance thermoplastics, ceramics and metals.

Zero-gravity construction

Roscosmos’ future plans for its domestic lunar program will reportedly see “the launch of construction of large-scale structures with the use of additive technologies and local resources.” Exactly how this will be done though is still subject to speculation. Russia’s Lavochkin Scientific and Production Association, which has a number of space-related contracts with the International Science and Technology Center, has previously suggested that construction on the Moon could be undertaken by a solar-powered, regolith sourcing 3D printer.

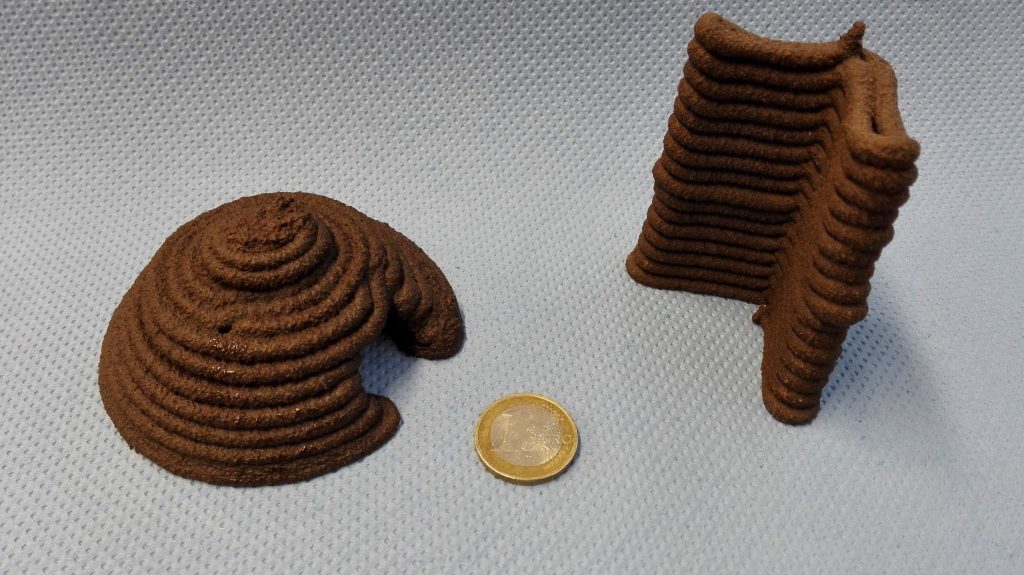

At ESA, and other research institutes, similar rudimentary efforts using regolith simulant materials have been undertaken to prove their 3D printability. Speaking with Dr. Advenit Makaya, ESA Advanced Manufacturing Engineer in Materials and Processes, current efforts in on-site space fabrication may be more conservative than the agencies would have us believe. “In the distant future, I’m not as optimistic as Elon Musk,” Dr. Makaya comments, “[…] But a foot on Mars, I think so, I hope so […] having a colony on Mars, honestly no.”

In addition, he believes that autonomy will be key to 3D printing’s success in space. “One thing about printing on a planet, is you are not going to have an [astronaut] standing next to machine pressing the buttons […],” said Dr. Makaya, “Most probably we will send the machines before we send the humans so they can print the ground for us.”

For all of the latest aerospace news from 3D Printing Industry subscribe to our newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows a view from the ISS taken by Russian cosmonaut Aleksandr Samokutyaev. Photo by Aleksandr Samokutyaev/Roscosmos