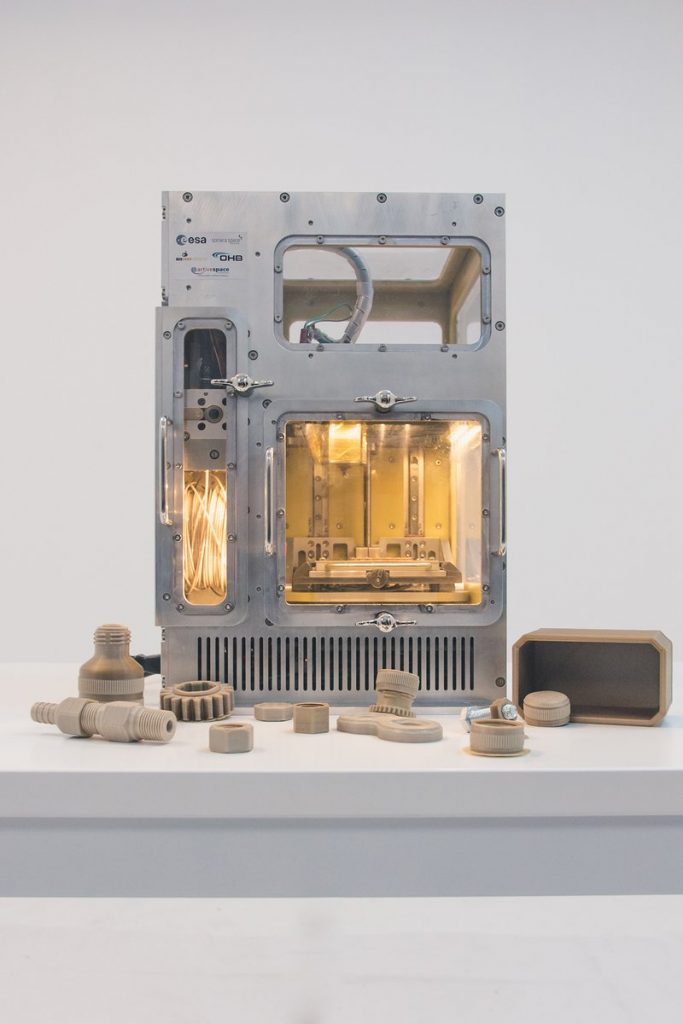

After two years in development, Project MELT (Manufacturing of Experimental Layer Technology) has resurfaced with a prototype microgravity 3D printer.

Made for the European Space Agency (ESA) the Additive Layer Manufacturing (ALM) breadboard machine is designed to 3D print high performance polymers aboard the International Space Station (ISS) and other off-world locations.

The collaborative behind Project MELT

ESA’s Project MELT has been undertaken by a consortium of 5 European technology companies.

A member of the ESA Brokers network, the Portugese non-profit organization Instituto Pedro Nunes is working to establish a connection between the sci-tech development environment of the ALM machine, and its potential commercial applications.

SonacaSpace is contributing its structural, thermal and mechanical engineering expertise to the project from a foundation of more than 30 years in the business.

Bringing gravity to the collective, OHB System AG adds its specialism as a developer of low-orbiting and geostationary satellites.

Active Space, is the fourth member of project MELT offering “bespoke electro-mechanical systems for extreme harsh environments” qualified for high gravity and high temperature radiation environments.

The final member of the team is Portuguese 3D printing technology startup BEEVERYCREATIVE, that has been responsible for the overall design and development of the 3D printer prototype and its operating software.

Microgravity Additive Layer Manufacturing machine specifications

At present, exact specifications of ESA’s ALM is unknown. Out of necessity, it is compact and robust by design. Materials that can be 3D printed in the process are defined as “engineering polymers with high end mechanical and thermal properties.” From the photos, sample objects appear to be made from a PEEK or PEKK like filament, and the machine clearly uses FDM/FFF based technology 9 see spool in section on left and print bed).

FDM/FFF is also BEEVERYCREATIVE’s expertise, as evident in its BEETHEFIRST 3D printer.

Made in Space

As 3D Printing Industry followers will know, American in-space manufacturing company Made In Space has had a 3D printer (the Additive Manufacturing Facility/AMF) aboard the ISS since 2014.

The AMF has a print volume of 140 x 100 x 100 mm (L x W x H) and works on an open materials platform. The grade of materials available for this system are “space-friendly” and include ABS, Green PE and PEI/PC.

Recently, the company has also been awarded a NASA Phase 2 Small Business Innovation Research (SBIR) for development of a microgravity metal 3D printer.

3D printing at ESA

At ESA, a great deal of investment has been made into companies using 3D printing to build next generation rocket engines.

In December 2017, the Ariane Group signed a $75 million contract with ESA for the development of engine tipped for release in 2030.

With the UK Space Agency, ESA has also contributed £60 million (approx. $85.1 million) to SABRE engine development.

Also in development is ESA’s 3D printed Lunar and Martian regolith project.

For updates on Project MELT and news from ESA, NASA and more, subscribe to our industry-leading newsletter, follow us on Twitter and like us on Facebook.

Looking for a new project? Sign up to 3D Printing Jobs here.

Featured image shows ESA’s Microgravity 3D printer. Photo via BEEVERYCREATIVE