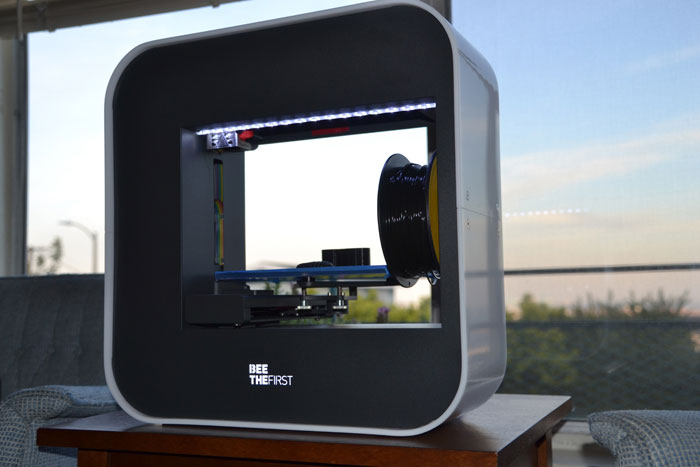

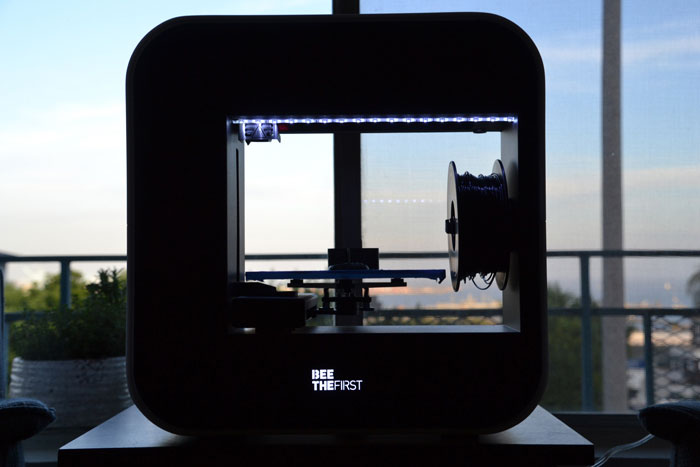

How apt that the first 3D printer that I’d have the opportunity to review would be titled BEETHEFIRST (BTF)! Manufactured by BEEVERYCREATIVE (BVC), out of Portugal, the BEETHEFIRST desktop 3D printer sprang out of the company’s initial business of producing low-cost microcontrollers, R2C2. After developing what they considered to be high quality boards, the engineers behind R2C2 decided that they could make a high quality 3D printer. And so, BEETHEFIRST was born!

I have to warn you that, due to a human-computer communication error, this may not be a typical unboxing and review. Unfortunately, as I was deleting photos from my computer, I accidentally deleted my Photo Booth Library, as well. There go a thousand pointless pictures of me making faces with different filters, in addition to the videos of my unboxing! Luckily, I have some footage of the BEESOFT software and my calibration of the machine recorded with another program and saved to a different folder. Plus, I’ve got a brief chat with the BVC customer service team that tried to help me through a jam.

I was so stoked to open up and try out the BTF 3D printer. Having seen pictures of it online, I knew that it was going to be really beautiful. And, the machine is a plug-n-play. Unlike my own Bukobot, I had a feeling that the BTF would both be easy on the eyes and easy to use. From the beginning, it seemed that the BVC team is all about a comfortable user experience. I opened up the box and found the printer expertly packaged, as demonstrated in the video above.

In addition, the printer comes with a kit of tools (a pair of tweezers, a metal spatula, blue painter’s tape, and an allen wrench), a manual, the magnetic print bed, and all of the necessary plugs (USB cable and power plug). I really do have to emphasize how well the BTF was packaged. Anticipating both the rough handling that may occur in shipping and the user experience, the printer itself is cushioned by several blocks of foam – beneath the printbed, next to the extruder, etc. – which are numbered so that you can remove them in the proper order. I felt the designer of the machine holding my hand through the printer’s unboxing, so as not to do any damage to his lil baby. I’m sad to say, however, that I’m really bad with babies.

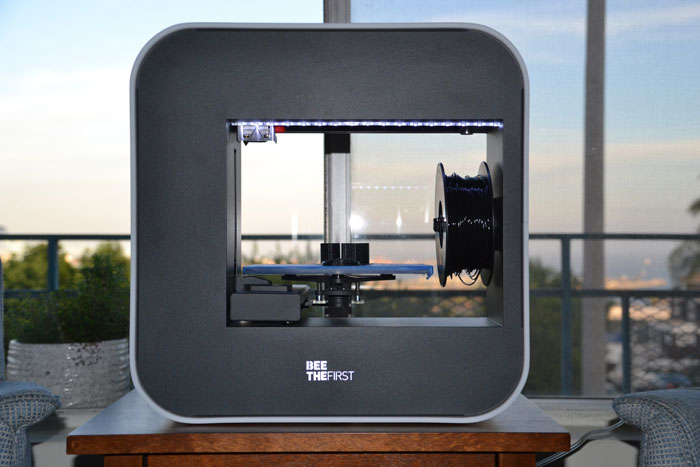

Plugging the printer in and setting it up was a charm. After attaching the magnetic buildplate, I plugged the printer in and, instantly, it began to whir with life. The print bed shifted to its home location and the machine began to glow with its lights lining the interior of the square printer and lights behind the BTF label. This was, indeed, a good looking product. My wife asked if the BVC people would just give me this one to replace my old RepRap eyesore.

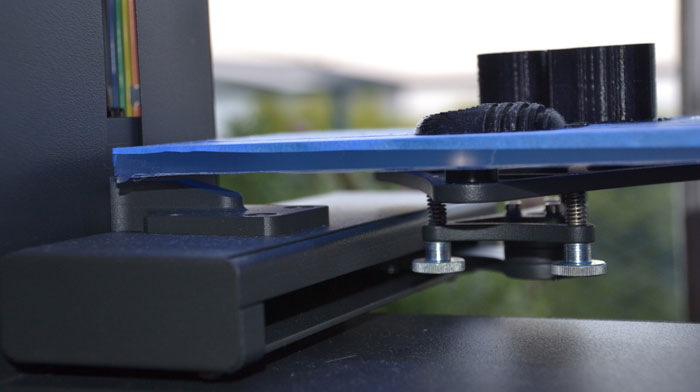

As the manual dictated, I downloaded the BEESOFT software for Mac. The software is still in beta, so there were a couple of bugs that I encountered, either relating to the software itself or some annoying features of OSX Mavericks. For instance, upon first startup, all of the program’s text was in wingdings that looked like this: ⌧ . After relaunching it, however, there was my good, ol’ mutt of a language, English. The software then led me through the bed calibration process, something I’d hoped would be fully-automated, but turned out to be semi-manual. You’re instructed to slip a piece of paper under the extruder, as is the case with most RepRaps, and, first, electronically adjust the bed until the paper is neither caught nor loose under the printhead. Then, the extruder moves to the front left and front right of the printbed, so that you can manually twist the adjusting screws until you’ve achieved the same effect at each point on the bed. For a video of me fumbling through the process, watch below. For a professionally shot tutorial on how to calibrate the bed, visit the BVC website.

After that, you’re able to start printing. Like the open source Repetier-Host software I’m familiar with, it’s easy to import .stl files to BEESOFT, as well as rotate and scale them. Unlike Repetier-Host, there’s not much more fine-tuning that you can perform. When you’re happy with your model and you click print, you’re greeted with a few different options: low or high detail, low or high density, rafting or no rafting, and support structures or no support structures. In this way, it seemed that the BTF was designed for entry-level consumers, who don’t want to be overwhelmed with a series of complicated options. I figured: if it prints, then this will certainly satisfy most people who don’t want to fuss over their appliances.

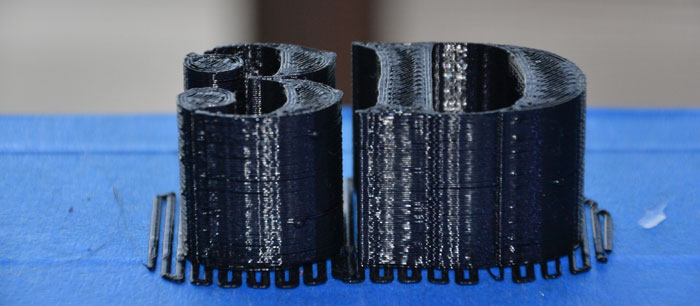

My first prints were actually pretty unsuccessful. I printed the 3DPI logo, but after one print, I kept experiencing the same problem as seen in the video below:

I sent the video to the BVC team, who responded with some helpful advice:

According to what you are telling us and from what we could see in the video, and without more information, we have identified two likely causes: the printing table may be well calibrated on the left and a bit away on the right side. With this, the printing process gets grabbed on one side and not on the other, and therefore the model gets dragged. Calibration is a small learning process ;). We are sure that with few attempts and errors, everything will be fine.

Carla from Customer Service was right! In order to calibrate the bed, you really do have to feel it out and ensure that each point during the calibration process has about the same level of tug on your piece of paper. If there were some way to make the printer’s calibration automatic or more exact, I don’t think I would have had issues with these initial prints at all. And, after getting it down, I was able to print a few different objects.

As Carla suggested, I started with the BVC bee logo, which came with BEESOFT. I was also able to print a series of conveyor belt gears for my wife’s boss that seemed to come out pretty well. Because I have no CAD skills, the gear model was made as a flat image in Illustrator and extruded in the latest edition of Adobe Photosho CC. I followed them up with the 3DPI logo and a couple of higher detail prints. The relatively small print volume (on paper) didn’t seem all that small to me at about 190mm x 135mm x 125mm. I couldn’t print an Iron Man helmet, but I could print a standard-sized mug. My more detailed CAD models were messed up; they came out looking good, with great 100 micron resolution, but not how I intended. So, I threw them in the recycling. I had no idea that those were going to be my last prints on the BTF.

Having printed a number of items in BVC’s provided black filament, I wanted to see what the feedstock changing process was like. I asked BVC if it was okay to experiment with materials from other manufacturers and speciality filaments, like Laywoo-D3, to which I received the following reply:

We do not recommend the use of other materials in BEETHEFIRST that are not completely validated by our team of R&D, because this may cause a decrease in the performance of the printer, or even jam the extruder.

Our goal is to provide the best possible experience and we only recommend materials that have been thoroughly tested by us. This does not mean it does not work . 😉 Anyway, we can tell you that we are testing new colours and new materials, and creating printing profiles. So, we will have news soon 🙂

Instead of starting off with something weird like Laywoo-D3, I figured I’d start with a pretty simple material like some translucent orange PLA, from Makerbot, that my wife had gotten me for Christmas. Switching out the filament was actually kind of fun because of BTF’s semi-automated process. You first unload the filament; the software automatically retracts it a bit from the extruder head and you manually reel it back through the windy tube hidden in the ceiling of the printer. You then load a new filament by inserting it through that same little hole you pulled the old feedstock out of, pushing it back through that windy tube and into the extruder. It’s just like a RepRap, except that your filament gets to have a fun trip that leads pretty flawlessly into the printhead. When you’re done, you can select a prewritten filament profile: PLA Black, PLA Yellow, etc. I chose what I thought would most match my Makerbot material: PLA Translucent.

As you may have already guessed, I should have heeded BVC’s warning. Printing started off okay, with a bit of translucent goop hitting the print bed, but, soon, it was jammed. I tried unloading and reloading the filament a few times. When that didn’t work, I tried to put the old BVC filament back in. Finally, I reported the problem to BVC, who scheduled a Skype call to troubleshoot. They led me through the process of taking the hood off the thing, removing that fun plastic tubing that carried the filament to the extruder, and feeding the filament in by hand. They had me unload and reload the BVC filament a few times and, even though we managed to get it to push through the print head manually, the printer no longer seemed to know how to drive the feedstock through the extruder on its own. At that point, the BVC team told me that they’d have to work on the machine in person. Though I was too busy futzing through their instructions to recording the troubleshooting process, you can meet the nice people who helped me out, Sandra and Marcelo, in the video below.

I definitely don’t blame what happened on the BTF machine or the BVC designers. I had been warned not to try untested filaments and I went ahead and did it anyway. On the Skype call, they had told me that this warning wasn’t because they wanted to force customers to rely on their own feedstock, but simply because they wanted to ensure a positive user experience. The BEESOFT’s filament profiles were specially calibrated to specific material types, colours, etc., with temperature settings made for each feedstock.

What is a drawback about the BTF, for people used to more flexible RepRap-type 3D printers, is that users are pretty limited in their ability to modify the printer’s settings. Had I been able to access an advanced settings menu, my experience with the BTF would have probably still culminated in an extruder jam, but it would still be a nice option. For consumers who don’t plan on getting too experimental with their machines and content with one filament supplier, however, they would probably be extremely happy with the product.

At the same time, my experience with the plug-in-play 3D printer taught me a couple of valuable lessons. An open source model to designing 3D printers and software opens up a printer to a much larger community. As users tinker with their machines, different filaments, etc., they’re able to offer up their knowledge to others using the same 3D printer. In the case of feedstock varieties, these users would be able to upload their own Slic3r profiles to the web. That way, someone like me could download a MakerBot Orange Translucent BEESOFT Filament Profile and print without much of a problem.

More importantly, having purchased my Bukobot from its local manufacturer, Deezmaker in Pasadena, gives me the ability to take it into the shop and have it looked at by its own manufacturers. This shouldn’t necessarily inhibit anyone from buying a 3D printer from abroad and, in particular, the BTF was a joy to work with until my little roadblock. But, in considering the purchase of a 3D printer, maintenance and assistance should be kept in mind, especially for the less mechanically inclined, like myself. It will be much easier to overcome problems and perform upgrades, if you can take your printer to someone knowledgeable, who doesn’t live so far away.

In the case of BVC, it’s possible that they’ll start growing substantially. After a great deal of interest at the 3D PrintShow in New York and an increased number of customers in Europe, the company is in the process of adding ten more team members to their already substantial office of 30 people. It’s considered one of Europe’s 50 most exciting startups and they’re planning to start shipping to North America and Latin America soon. As they ship more and more printers around the globe, they’ll be able to open retail shops where they can assist customers without the need for Skype. Or local resellers will become familiar with their BEEVERYCREATIVE product and help customers in the surrounding neighborhood. This seems to be a concern that may affect all 3D printer manufacturers. Until the technology becomes a bit more refined and foolproof, reliance on local manufacturers or resellers will likely be a necessity for average desktop 3D printer consumers. I can also envision the rise of a mobile Geek Squad-type — 3D printer repair services that can come to your door and fix any 3D printer you’ve got. [Ed: Now there’s a business model we haven’t seen yet! Wonder who’ll jump on that first.]

All in all, my experience with BEETHEFIRST was a good one. I had the chance to write my first review of a 3D printer, which was a beautiful and easy to operate machine. I also got the opportunity to learn some valuable lessons. For instance, when someone politely tells you not to mess up their 3D printer by putting untested filaments in it, you should listen.

All photos by Danielle Matich, unless otherwise specified.