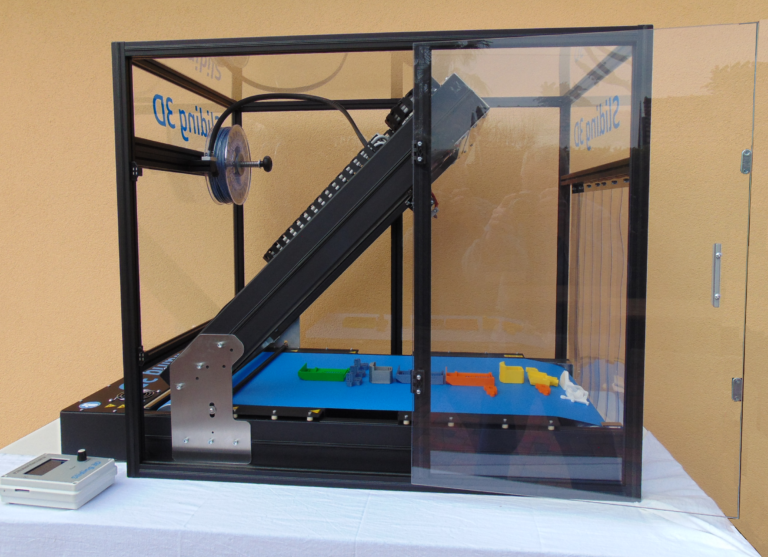

From October 12 through 14 2018 Robot Factory, an Italian 3D printer manufacturer showcased its Sliding-3D printer at Maker Faire Rome.

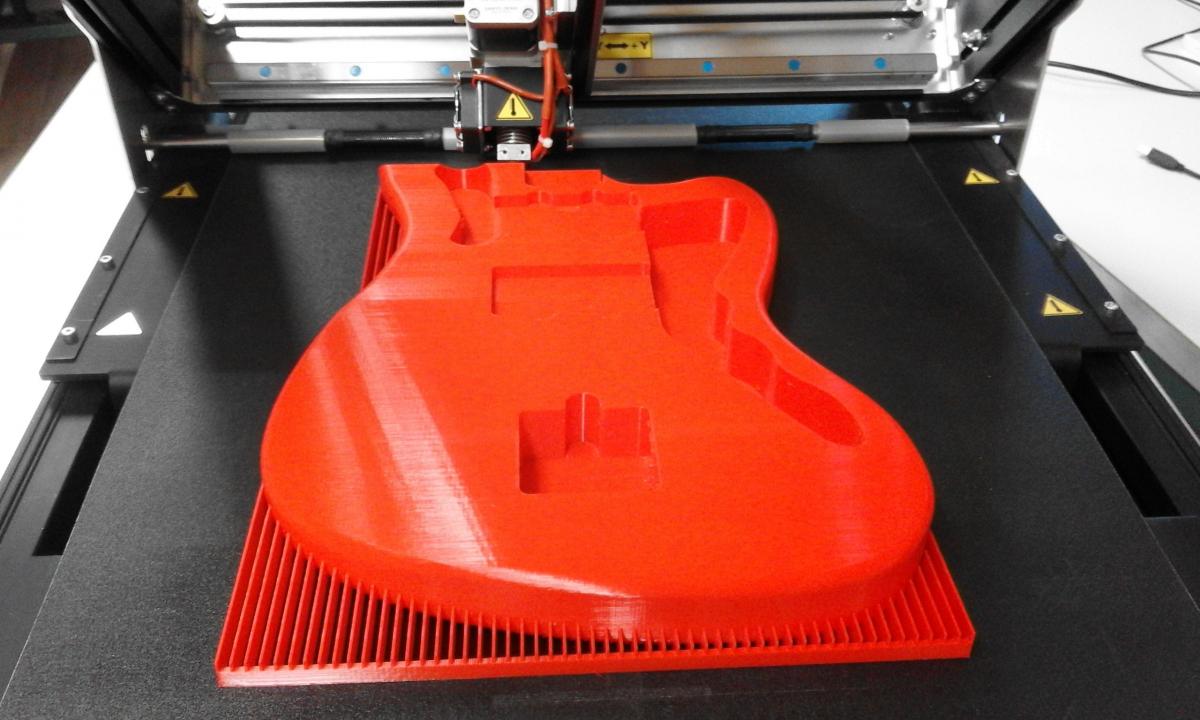

A so-called ‘infinite’ build 3D printer, the Sliding-3D uses a 45° angle extruder and a conveyor belt as a build platform. Robot Factory calls its Sliding-3D printer “a sort of “desktop factory.” With its continuous 3D printing feature, the company also says that the 3D printer is more time and cost-efficient compared to traditional fixed-build FDM printers.

Continuous 3D printing

Though a novel concept, the Sliding-3D is not an entirely new concept. AMy other manufacturers have been seeking similar solutions to ramp up 3D printing for production-scale output.

In 2017, Brooklyn-based 3D print bureau Voodoo Manufacturing introduced a robotic arm in its workspace. The automated arm collects finished models from a stack of 3D printers and places them on a conveyor belt. Without stopping the 3D printer begins the next task in the queue. And the process continues. According to Voodoo, this has reduced the cost of production by 90%.

Stratasys has its solution in the Infinite Build System, a continuous production FDM printer.

And Dutch research institute TNO is working on the nicknamed “Sushi printer” with BigRep.

In appearance, Robot Factory’s Sliding-3D printer is most similar to the Printrbelt which was in development at the now-defunct Printrbot. Printrbot founder Brook Drumm, however, has hinted that more 3D printer experiments could be yet to come from him.

Environmentally friendly infinite 3D printing

Weighing 36 kg, Sliding-3D is an FDM/FFF printer with a conveyor belt build platform. Due to its forward-moving build platform, there are no limitations as to how long in length the Sliding-3D can print. The size of a print can range from 41 cm x 38 cm to ∞infinite.

Finished objects keep moving down the conveyor belt until they drop into an attached basket. This process can go on endlessly without interruptions and without a need for a machine operator.

Robot Factory also boasts of the environmental-friendly side of the Sliding-3D. It prints horizontal overhangs which require no support structure. Due to this, postprocessing takes less time and leaves less plastic residue.

The Sliding-3D extruder can handle temperatures of up to 280°C. Compatible materials include PLA, ABS, PETG, and other composites such as nylon, fiberglass, carbon fiber.

For high-temperature printing and protection against environmental effects, the 3D printer can be insulated with the Sliding-3D Box, a protective glass cell measuring 94 x 67 x 81 cm.

Technical specifications and pricing

Pricing of the Sliding-3D system is available on request. Full technical specifications can be found below.

3D printing technology: FDM/FFF

Printer measurements: 1.100mm x 570mm x 770mm

Build size: 41 cm x 38 cm x ∞ (infinite)

Layer resolution: 0.15 – 1.0 mm

Extrusion temperature: 280 °C

Supported filament materials: PLA, ABS, PETG, and other composites such as Nylon, High Impact Polystyrene (HIPS), Fiberglass, Carbon fiber

Recommended filament diameter: 1.75 mm

Extruder: A 45° angle single extruder

Weight: 36 kg

Connectivity: USB, SD card

Control device: PAD Esterno

For all of the latest 3D printer releases, subscribe to our 3D printing newsletter. You can also join us on social media: Facebook and Twitter.

Visit our 3D Printing Jobs to start a new career.

Featured image shows Robot Factory’s Sliding-3D printing. Image via Robot Factory