Stratasys (NASDAQ: SSYS) has announced two new 3D printing demonstration models, 3D Infinite Build and Robotic Composite. As previously reported Stratasys, believe the 3D printing industry is “maturing and evolving”. The news provides more details about how the company will approach this next phase.

We take a look at the information and put some of the claims into context.

3D dimensional infinite build

The first technology is described as “3D dimensional infinite build”. This technology is designed to fabricate large format parts from thermoplastics. As can be seen in the video, the machine prints on a vertical plane. This is to enable an “infinite length” of FDM printed components.

Aerospace giant, Boeing were involved with many aspects of the project and are exploring the use of demonstration 3D printing machines to “reduce cost and weight” in aircraft structures according to Darryl Davis, President of Boeing Phantom Works.

Leo Christodoulou, Director of Engineering, Materials and Structure of the Boeing Company said the Infinite Build technique, “Enables products to be made much larger and potentially unlimited length.” Christodoulou continues to say, “We look forward to a large ecosystem that offers large production, stability of processes and a robust base of design, materials and structures.”

Stratasys are also working with automotive manufacturers, Ford. Ellen Lee, Technical Leader for Additive Manufacturing at Ford Motor Company, says the technology “opens up opportunities for large scale fixtures and some of the large parts we have”.

To put this in context, other companies such as China’s Shining 3D are also tackling the issue of larger build platforms. The Shining 3D iSLA-650-Pro stereolithography machine has a 650x400x400 mm build platform and is in use by the automotive industry for making rapid short production runs. These runs can also be completed quickly, and commonly SLA has a higher surface resolution than that offered by FDM. One application is in the mold making process for car bumpers, the final part is then completed using injection or reaction molding.

However rather than rapid prototyping, the new Stratasys machines appear to be targeting production. Ford’s Ellen Lee says, “In the mid term I think the materials development side has a lot of opportunity especially looking at automotive materials that meet all the requirements for automotive applications.”

Richard Garrity, President of Stratasys Americas says the company has, “flipped traditional FDM technology on its side and combining it with a tool changing capability.” This suggests that like other hybrid 3D/CNC machines post production finishing may be completed within the same machine. In other hybrid machines additive layers are polished by CNC milling tools. This can speed up the process, and also enable the finishing of hard to reach areas of a component.

Large format 3D printing

Garrity says the Infinite-Build machine is ten times faster than current FDM technology and, “produces parts measured in feet versus inches.” As previously reported by 3DPI, Norsk Titanium is using Rapid Plasma Deposition (RPD) to produce large format titanium components. The RPD 3D printing technique is designed to be a high throughput additive manufacturing method that can deposit 10 kilo’s of metal every hour. Norsk Titanium machines will be used to produce aerospace components such as brackets and the company has already shipped several test pieces to begin the qualification process.

At the micro scale and for more detailed components, Optomec’s Aerosol Jet 3D printing technology is already in use for the mass production of electronics. Using nano-particle inks the company’s machines print electronics inside millions of smartphones for a major cell phone manufacturer.

Furthermore, the Voxeljet VXC800 is a binder jetting 3D printer with a build platform of 850x500mm with the length dimension composed of a conveyer belt. The Voxeljet machine is designed to offer users the ability to create sand molds for foundry casting. The company targets the automotive industry and also offers a larger format machine with a build platform of 4000x2000x1000 mm.

Additive + Subtractive = Hybrid 3D printing

The hybrid approach, or combining subtractive techniques with additive is an area that the America Makes working group CAM-IT is exploring. Given the widespread use of CNC tools and the increased axis options available this approach is likely to be pivotal in the integration of 3D printing with mass manufacturing.

Companies such as Optomec are active in this area and have designed their LENS printing system for integration with CNC machines. In an interview with 3DPI, Optomec’s Ken Vartanian explained,

“From our vantage point LENS directed energy deposition is a more flexible metal additive manufacturing approach that has not, in my opinion, been fully recognized or exploited by industry”

Additionally in 2014, the German Company DMG MORI demonstrated the integration of a 5-axis CNC milling machine with a directed energy deposition 3D printing technique. The Lasertec 65 3D machine uses a 2 kW diode laser and a powder nozzle to reach speeds the company claim are ten times faster than powder bed machines.

Robotic Composite 3D demonstrator

Scott Crump says, “The second technology allows us to use a robot to get into areas in a 3 or 5 axis way that has never been done before.”

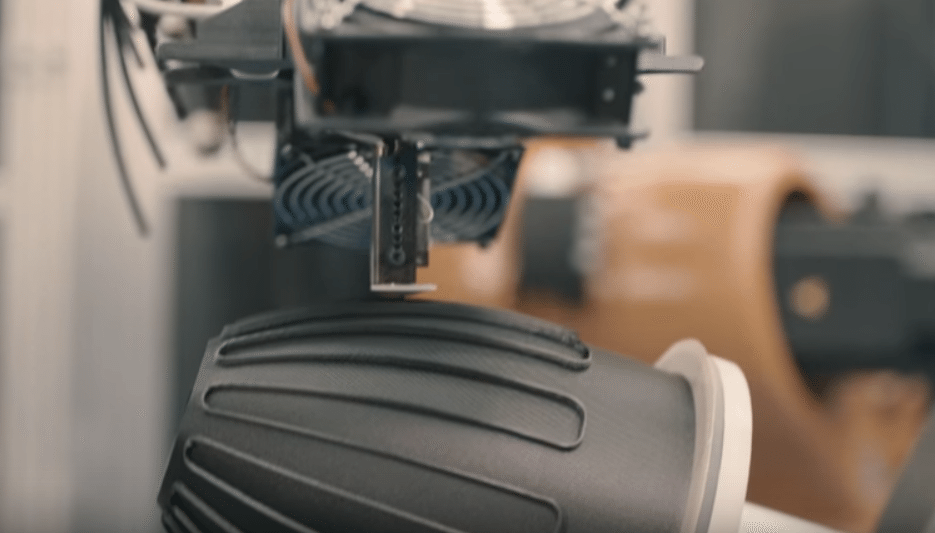

The Stratasys video shows an extrusion head, surrounded by four fans and mounted on a KUKA robot arm. To control the device Stratasys have partnered with Siemens. Arun Jain, Vice President of Motion Control at Siemens said, “It is a very exciting time for additive manufacturing.”

Roger Hart, R&D Engineering Manager at Siemens, said,

“With this project we bring the strengths of Siemens in CNC and CNC controlled robots with the strengths of Stratasys in FDM and elevate it by adding our CAD CAM and simulation tools so we produce a truly unique platform.”

Hart also gives some further detail, “One of the truly unique applications this brings to industry is the 8 axis kinematics of the robot and the tables.”

The demonstration models show how Stratasys will join other 3D printing companies engaged in the industrialization of 3D printing. Incorporating additive manufacturing into the factories of the future will certainly be a part of Industry 4.0 and Hart explains,

“This project enables a whole list of vertical integrations that haven’t been possible until now. From material feeders, to automation equipment, to robot loaders and unloaders, we can now span the whole vertical automation framework that is necessary in factories.”

Stratasys will demonstrate the new machines at the IMTS event in Chicago next month. The financial markets responded favorably to the announcement and in early trading the share price had increased by almost 5%.