Global mining and metals group Rio Tinto has entered into an agreement with metal additive manufacturing specialist Amaero to provide a high-performance aluminum-scandium alloy that can be processed into powder for 3D printing and deployed for high-temperature applications.

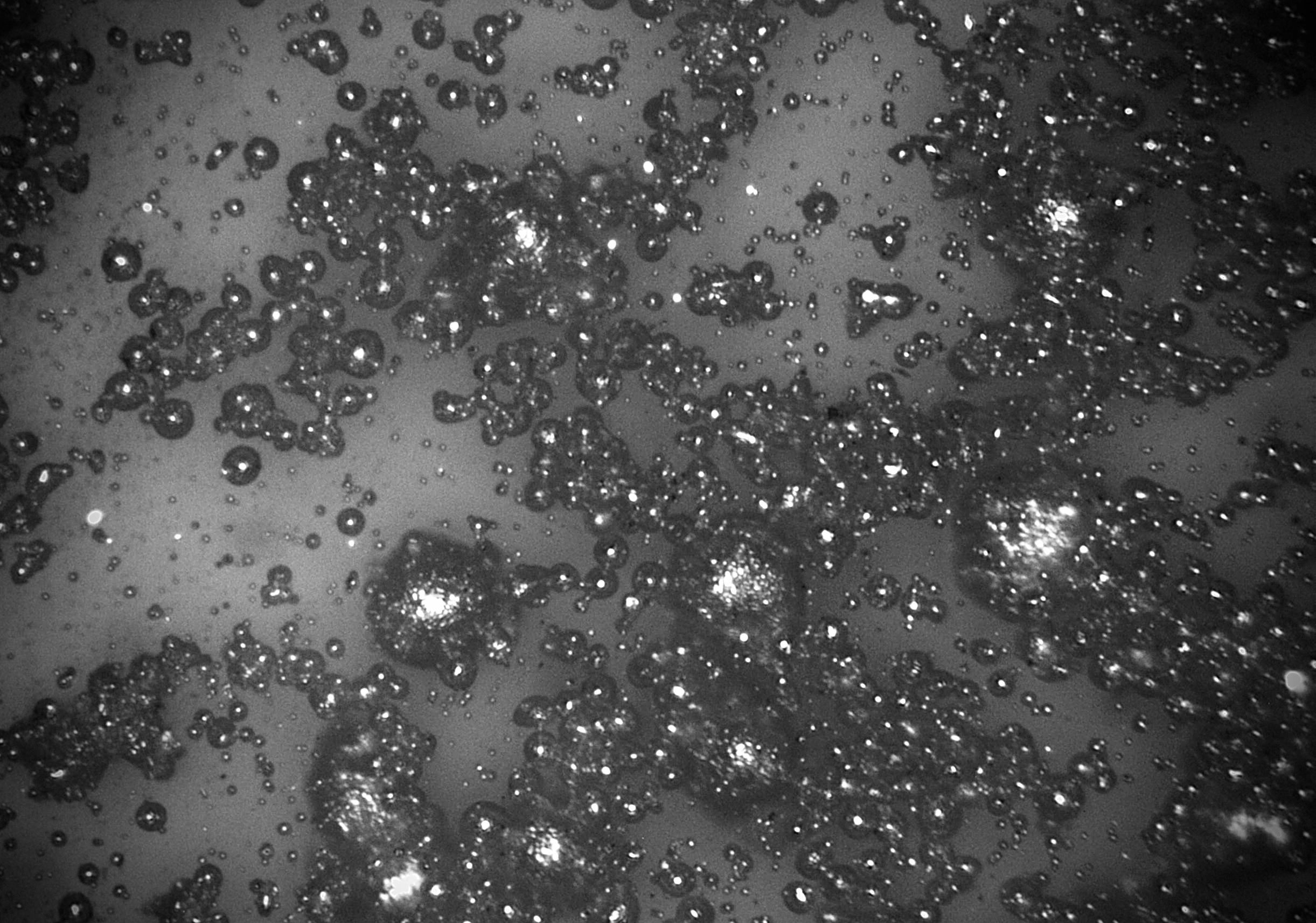

Through its new plant in Quebec, Canada, Rio Tinto will provide the first North American supply source of scandium oxide worldwide, which it will combine with low-carbon aluminum to create a specialized aluminum-scandium alloy. Rio Tinto will provide the first commercial batch of the alloy to Amaero to be processed into powder for 3D printing.

The deal will also see the companies work together to develop the supply chain for Amaero’s own Hot Operating Temperature Aluminum Alloy, Amaero HOT Al, and commercialize it for additive manufactured applications within the aerospace and defense sectors, among others.

“As a global leader in aluminum and the first producer of high-quality scandium oxide in North America, Rio Tinto is uniquely positioned to provide a secure source of aluminum-scandium alloy to the market,” said Tolga Egrilmezer, Rio Tinto Aluminum Vice President Sales and Marketing. “Aluminum-scandium alloy is the material of choice where lightweight, high-strength material with thermal resistance and good welding properties is needed, such as for defense and aerospace applications.

“This first sale demonstrates our ability to develop products that meet our customers’ needs, drawing on our technical expertise and world class assets.”

Responsibly produced aluminum-scandium

Scandium is a silvery-white, rare earth metallic element that can be utilized to improve the performance of aluminum alloys for 3D printing. Rio Tinto has been developing a process to extract high purity scandium oxide since 2019, and has since been perfecting the material to meet market specifications.

The process involves extracting scandium oxide from by-products generated in the production of titanium dioxide at the firm’s Rio Tinto Fer et Titane (RTFT) metallurgical complex in Sorel-Tracy, Quebec. By using the waste streams of titanium oxide production, the method removes the need for additional mining and also has the potential to lower production costs.

Under the deal with Amaero, Rio Tinto will supply billets comprised of high purity scandium oxide and responsibly produced, low carbon aluminum from its hydro-powered smelters. Amaero will then process the billets into powder suitable for metal 3D printing, and offer the material to the market for use in various high temperature applications.

“We are very pleased to enter this agreement with Rio Tinto to purchase the first commercial batch of aluminum scandium alloy from a North American source,” said Barrie Finnin, Amaero’s CEO. “This is an important step in the commercialization of this high performance alloy that will be used in our breakthrough 3D metal printing technology. We look forward to working with Rio Tinto to progress the production of the alloy so we can commence the qualification process with key customers in the aerospace sector and other industries.”

Developing Amaero’s HOT Al alloy

As part of the newly-announced agreement, Rio Tinto and Amaero will work together to develop the supply chain for Amaero’s HOT Al alloy and will seek to commercialize it for use within the aerospace and defense sectors.

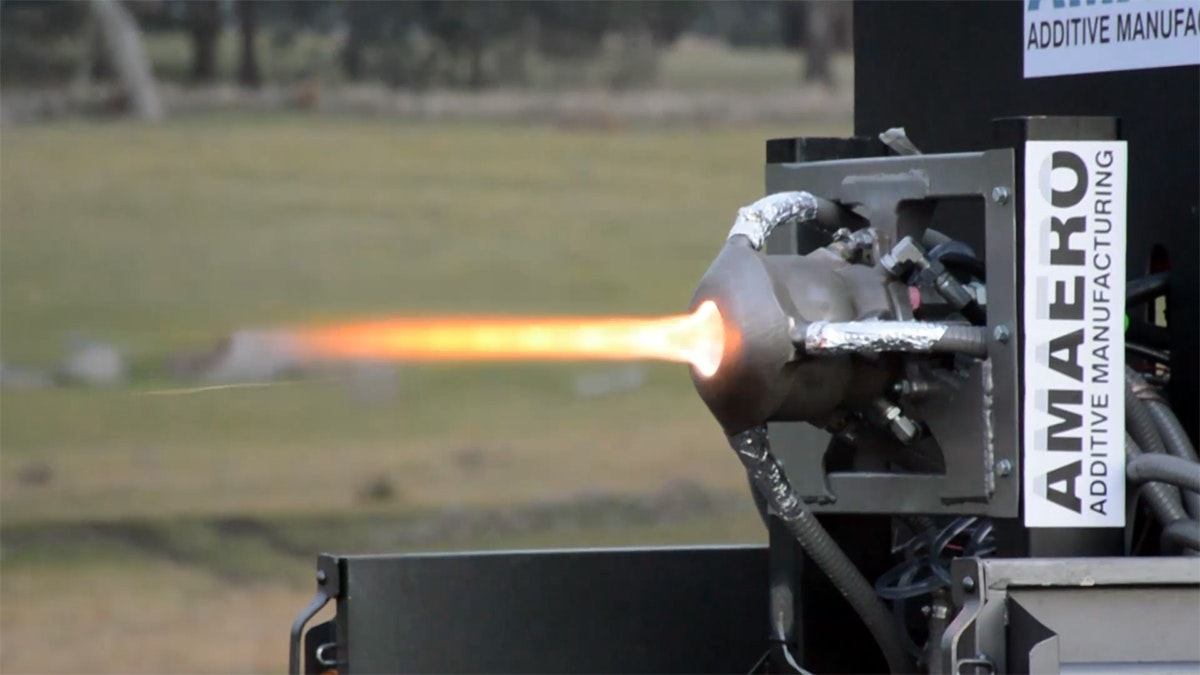

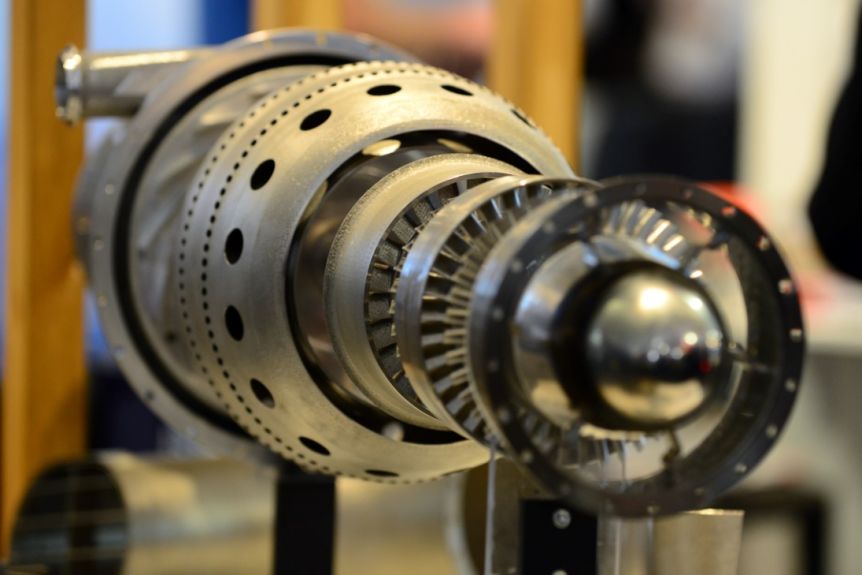

Amaero was founded in 2013 as a spinout of the Monash University Centre for Additive Manufacturing (MCAM) in Melbourne, Australia, before going public on the Australian Securities Exchange (ASX) at the end of 2019 in an IPO that raised $8 million. It was at Monash that the firm’s HOT Al aluminum-scandium alloy was originally developed, with Amaero now holding exclusive global license rights to the alloy.

HOT Al is an aluminum alloy with a high scandium content that can be heat treated and age hardened after 3D printing to increase its strength and durability. The scandium provides the material with high tensile strength and stability up to temperatures in the region of 260°C.

In June last year, Amaero announced HOT Al had entered the fourth and final stage of international patent approval. Later in the year, the company received a purchase order from aerospace manufacturer Boeing for the production of metal evaluation components.

Aluminum 3D printing developments

Aluminum for metal 3D printing is seeing an increasing stream of alloy development, as companies seek to develop metals with enhanced mechanical performance for wider applications in the automotive and aerospace sectors, among others.

In 2019, California-based HRL Laboratories developed a powder format aluminum 3D printing material which it claimed was “the strongest additive manufacturing aluminum to date.” Soon after, materials manufacturer QuesTek Innovations LLC began developing a new aluminum alloy 3D printer feedstock in collaboration with the German Aerospace Center (DLR), designed to exhibit high strength and temperatures between 200 and 300°C.

Last year, German metal 3D printer manufacturer SLM Solutions collaborated with manufacturing conglomerate Honeywell to qualify parameters for 3D printing thicker aluminum aerospace parts. Meanwhile, DED manufacturer Optomec advanced the material capabilities of its LENS 3D printers to enable them to deposit any aluminum alloy, and aluminum specialist Fehrmann ALLOYS launched its latest high-performance aluminum alloy for 3D printing, AlMgty 90, at Formnext Connect 2020.

More recently, Aluminium Materials Technologies (AMT) has partnered with the University of Birmingham to enhance understanding of the metallurgy of its 3D printed A20X aluminum alloy, and Desktop Metal has teamed up with Uniformity Labs to launch a new sinterable aluminum powder for use with its binder jet 3D printing technology, Uniformity 6061.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Amaero and Monash University’s 3D printed jet engine. Photo via Amaero.