In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments and partnerships in the wider 3D printing sector.

Today’s edition features a number of investments, awards, software updates, automotive updates, and even novel applications such as a 3D printed razor and a wheelchair built specifically for dogs.

Read on for the most recent updates from ORNL, ASTM International, FormFutura, University of Delaware, America Makes, Auburn University, Boeing and more.

New partnerships and investments in 3D printing

Oak Ridge National Laboratory recently announced an investment in a 3DCeram Sinto C900-Flex 3D printer. The ceramic printing system will be used to make oxides and nitrides for the production of surrogate fuels and leading edges, and was the first instance of Oak Ridge purchasing capital from the company.

Corson Cramer, a researcher at Oak Ridge, stated, “3DCeram had the most innovative technology with paste and laser from the top. We were excited about the accuracy and resolution the machine provided as well as the size. Before learning about the C900, we were having issues with the size of our parts.”

Elsewhere, 3D printing software developer Link3D announced a successful customer launch with Nordic logistics company PostNord, whereby Link3D provided software for PostNord to scale up its medical device 3D printing operations. This push into the Nordic region is reportedly in line with Link’s wider vision of global penetration, and focused specifically on delivering a secure platform for physicians to produce 3D printable models from patient X-rays.

Jim Carlson, Link3D’s EVP Customer Operations, added, “The commitment to Additive Manufacturing and the confidence PostNord has placed in Link3D, as they drive their innovation is not only exciting for Link3D, but showcases the impact digital transformation has when scaling operations within the additive industry.”

Materials suppliers FormFutura and 3D Printlife recently announced a strategic reseller partnership to bring FormFutura’s 3D printing materials to a European customer base. 3D Printlife’s initial offering will comprise five of FormFutura’s filaments, including ApolloX, Centaur PP, TitanX, Galaxy PLA, and Silk Gloss PLA.

Finally, the University of Delaware recently purchased a six-axis “Factory in a Tool” manufacturing system from microdispensing specialist nScrypt. The University’s Electrical and Computer department has already stated plans to use the machine, which features a SmartPump toolhead, to 3D print functional devices with integrated electronics, sensors and radio frequency communication functionality.

Mark Mirotznik, Professor of Electrical and Computer Engineering at the University, stated: “We selected nScrypt’s Factory in a Tool system because it is honestly the only commercial tool that meets all of our requirements for multi-material and multifunctional AM. nScrypt is unique in the number and quality of the various printing technologies that can be combined within a single integrated platform.”

Funding news from Amaero and America Makes

3D printer manufacturer Amaero announced that it had received firm binding commitments to raise a total of $9M via a share placement, following an announcement that the firm had entered a trading halt. The company is set to issue 16.36M ordinary shares to institutional and sophisticated investors at 55 cents a share, which represents a 19.9% discount when compared to the five-day volume weighted average price. Amaero has stated that it will use the capital to fund equipment purchases, capital expenses, research and development, and working capital.

The news comes following a purchase order, the week prior, from aerospace manufacturer Boeing for the production of metal evaluation components. Although the order was a one-off, Boeing has stated that it may close more deals with Amaero if the products are of a certain standard.

Barrie Finnin, CEO of Amaero, stated, “The purpose of Boeing’s Global Supply Chain program is to provide access to companies like Amaero to identify opportunities to support global programs within Boeing. We have worked closely with Boeing’s Global Supply Chain people to unearth a multitude of opportunities within several Boeing programs for Amaero to supply prototypes and production. We look forward to working on the evaluation parts in our facilities in Melbourne and El Segundo and continuing to build our relationship.”

Elsewhere, America Makes recently awarded regulatory firm ASTM International and Auburn University with more than $260,000 to develop a comprehensive additive manufacturing cybersecurity training program. The partners will work closely with cybersecurity experts to address one of the key issues associated with digitized supply chains, with the ultimate aim of accelerating the adoption of additive manufacturing.

Paul Bates, a Lead Project Engineer at ASTM International, explained: “As additive manufacturing technologies are being broadly adopted, the need to counter cyber threats is becoming more prevalent. This award will help ASTM International’s Additive Manufacturing Center of Excellence (AM CoE) offer training programs to train the workforce and prepare it to combat cybersecurity threats.”

Automotive updates from Rolls Royce and Wevolver

Automotive manufacturer Rolls Royce recently showcased a large batch of metal 3D printed series components that had been given the DfAM treatment and topologically optimized. Many of the parts are end-use ready, and are intended to be welded onto the chassis of one of the firm’s models. The company, which operates under BMW, is already known for its use of additive manufacturing, although the recent showcase suggests a push towards full series production.

Elsewhere, engineering knowledge provider Wevolver, together with materials company polySpectra, recently announced the winner of the Make it Real 3D printing challenge. The founder of Evol Components, Heath Townsend, is set to receive $25,000 worth of 3D printing services and realize his concept of a bracket that clips onto the forks of a motorbike to secure an indicator light. The organic design is intended to mimic biological geometries, and will be fabricated in a new rugged 3D printing material, COR Alpha.

Raymond Weitekamp, CEO of PolySpectra, stated, “All of the finalists had amazing ideas, but Heath stood out for two reasons. First, he had been actively designing his products for additive manufacturing from their very inception. Second, he was ready to sell the final product within weeks of us demonstrating a functional prototype. Heath was ready for us to make his idea real!”

Novel 3D printing applications

Consumer product manufacturer Gillette, in collaboration with New York Giants star Saquon Barkley, recently launched a limited edition 3D printed Gillette x Saquon razor. The shaving device features an entirely 3D printed handle, the number 26 (Saquon’s signature number), and a football-inspired design. The company is currently giving the product away for free, with the competition set to run until December 31.

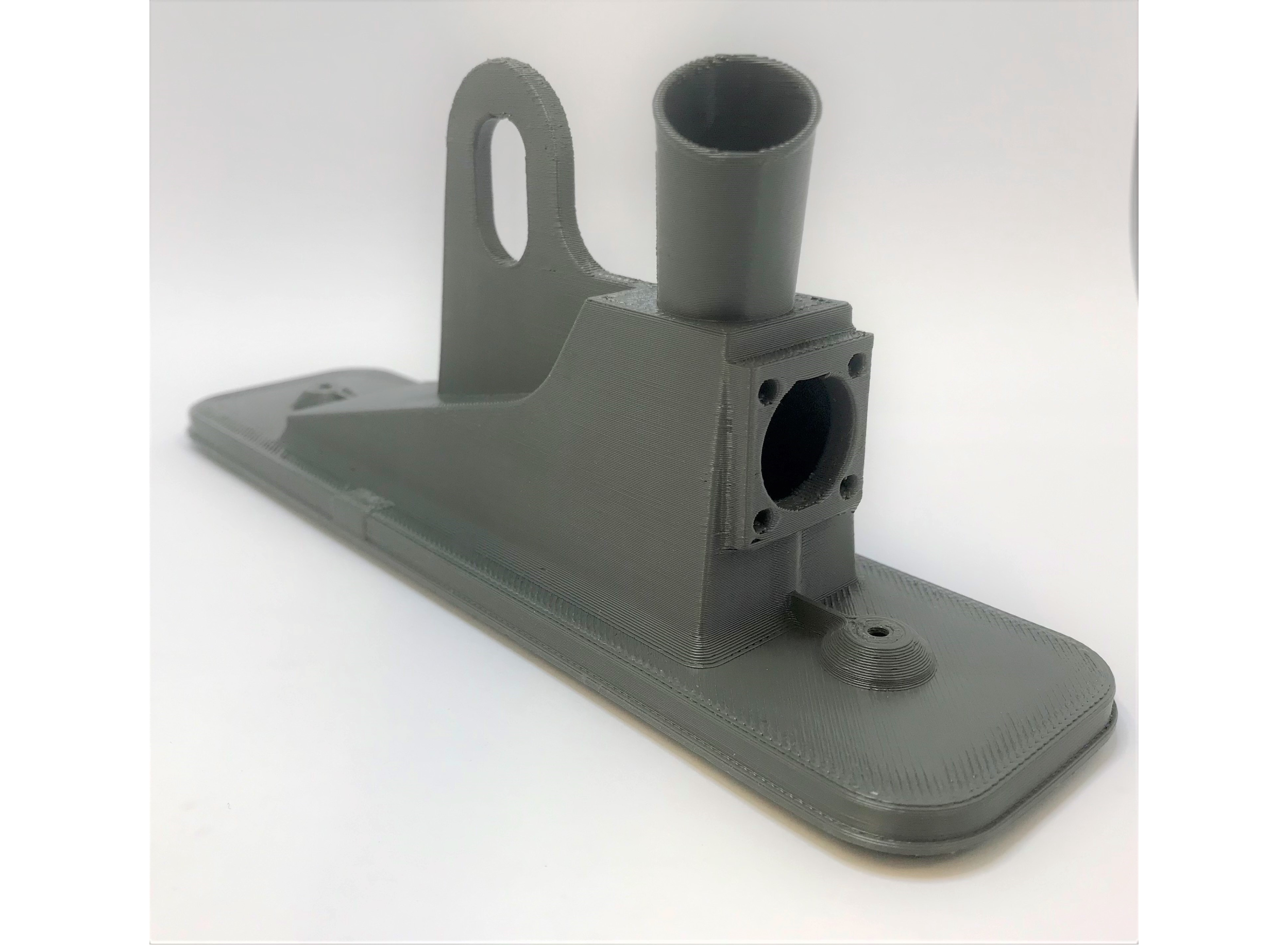

Elsewhere, in the Czech Republic, mobility start-up AnyoneGo is using 3D printing to produce custom wheelchairs for dogs that are unable to walk. The company’s lead designer, Jan Jiránek, uses a wheelchair himself, and uses Prusa 3D printers to manufacture 90% of the components in the novel devices. The wheelchairs are currently available in four sizes: Nano (dwarf breeds), Micro (Dachshunds), Small (French Bulldogs), and Middle (Border Collies).

Jiránek adds, “Using 3D printing allows us to create wheelchairs for individual customers and make any necessary changes. We can also quickly adapt to any new improvements in 3D printing technology.”

Software and material updates from Materialise and LEHVOSS

3D printing software developer Materialise recently launched its new SurgiCase software, a cloud-based case management system for the production of personalized 3D printed medical devices. The software serves as a central location for medical device companies and medical professionals to exchange data, communicate about surgical planning, and check case statuses, reducing administrative overhead.

Sebastian De Boodt, Market Manager Medical Software at Materialise, adds, “Now personalized medical devices are moving from novel to mainstream, medical device companies are confronted with new operational challenges. From the need for an image upload platform, to a way to keep their customers informed on the status of their order. For years, we’ve developed and perfected the SurgiCase software to increase the efficiency in our internal operations. By bringing it to the market as a software product, we want to empower other medical device companies to help even more patients with a personalized device.”

Finally, materials specialist LEHVOSS Group recently tested its LUVOCOM 3F 3D printing materials range in accordance with the EN 45545 standard, which comprises a number of fire-related safety tests. Having completed the tests, the company has proven the fire-resistance of its PEI, PPS, and PA filaments, meaning the materials can now be used to 3D print parts for railway vehicles in Europe.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on the wheelchair for dogs. Photo via AnyoneGo.