In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features an update on 3D printing appointments and job opportunities, as well as additive facility openings, aerospace acquisitions, advanced raceboat parts and a rather festive fabricated bauble.

Read on for the most recent updates from Uniformity Labs, Morf3D, GoEngineer, AMCM, Siemens, Fraunhofer ILT and more.

Sartorius hiring for an Additive Manufacturing Designer

Starting this week with vacancies, biotech firm Sartorius Stedim is hiring for an Additive Manufacturing Designer to work at its UK-based Stonehouse facility. The company is recruiting to aid its expansion into additive production, and the successful applicant will be responsible for designing optimized 3D printed parts.

Duties are set to include working with Sartorius’ engineering teams to turn concepts into designs, as well as developing ideal processing set-ups for its machines. Closely managing design documentation will also be important to the role, as candidates will be expected to support others during the commissioning process.

While being a strong problem solver would be helpful, candidates will also need relevant experience and to be proficient with CAD design software packages to be considered. The full job description for the role of Additive Manufacturing Designer at Sartorius can be found here.

$2 million high-tech maker space opens

Private engineering college, The Cooper Union, has opened a new state of the art maker space thanks to $2 million worth of funding from the New-York based non-profit IDC Foundation. The ‘AACE’ facility is designed to provide students with access to advanced fabrication equipment such as 3D printers, robotics and VR gear.

During a pilot phase in February the complex was opened to the public, and even though it has been forced to close due to the pandemic, the equipment has proved conducive to remote learning. In March, the faculty staff even managed to utilize the new resources to 3D print 1,500 protective face shields for local health workers.

“Students can submit a file online, a lab technician sends the file to the machine, and it’ll turn out more or less exactly the same as if a student was doing it in person,” said the lab’s Director, Harrison Tyler. “I think it ends up working really well both for what we’re dealing with right now, and hopefully where we’ll be in future.”

Uniformity Labs, ARBURG make appointments

Californian software and material producer Uniformity Labs has appointed former General Motors (GM) executive Alan S. Batey as an advisor to its senior management team. Batey, who joined the board in January 2020, boasts over 40 years’ experience, and was most recently GM’s Global Brand Chief for Chevrolet.

“As a leader in the global automotive industry, Alan’s knowledge is invaluable to us,” said Adam Hopkins, CEO and Founder of Uniformity Labs. “His commercial expertise is proven, and we are benefiting greatly from his unique perspective not only in the auto industry, but from his experience scaling businesses globally.”

German 3D printer and injection molding system manufacturer ARBURG has hired Jerome Berger as the new Managing Director of its Austrian subsidiary. Berger, who takes over from the firm’s German and Austrian Sales Director Oliver Giesen, will be tasked with growing its business, and optimizing its level of service there.

In Berger, ARBURG has appointed someone with technical and economic expertise, as well as experience in machine construction and the field of automation. Over the last few months, Berger has undergone extensive training, and now that he’s ready, he will work in-between ARBURG’s Lossburg HQ and Inzersdorf facility.

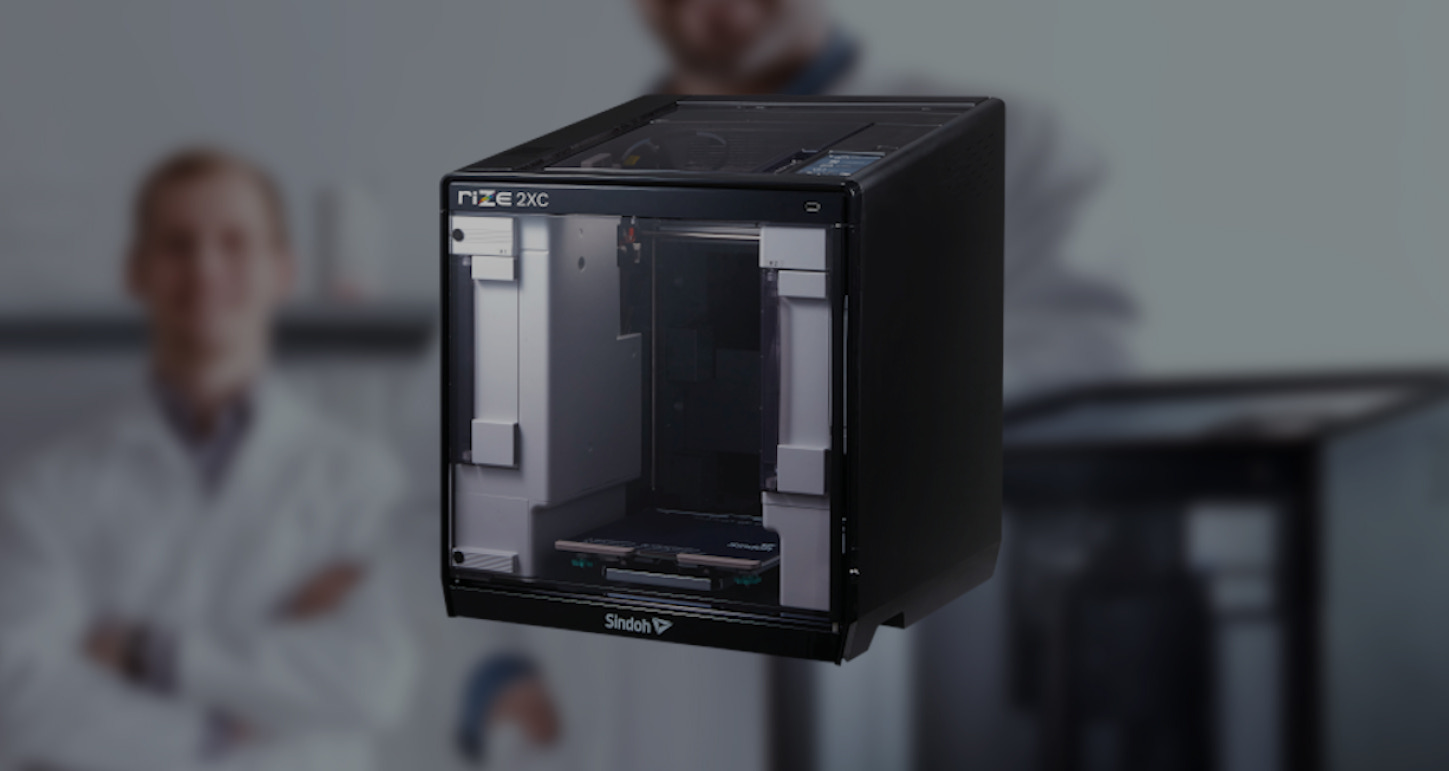

RIZE gains eco-friendly certification

3D printer manufacturer RIZE has announced that its 2XC desktop system and RIZIUM carbon filament have been granted GREENGUARD certification. The award is based on minimizing the chemical emissions of its machines and materials, and GREENGUARD products have to pass rigorous standards to become certified.

The announcement marks the firm’s fifth verified product, and makes it the number one provider of GREENGUARD-safe printers in the industry. “We congratulate RIZE on yet another milestone, and its commitment to the UL GREENGUARD certification,” said Alberto Uggetti, VP and GM of UL’s environment and sustainability division.

“Organizations can’t afford to compromise team safety when 3D printers are on desktops or in remote workers’ homes,” added Andy Kalambi, CEO of RIZE. “At RIZE we’re proud that the RIZIUM Alliance will lead the industry in UL GREENGUARD compliance, and have committed ourselves to adhering to the highest standards.”

VELO3D, Redwire and Morf3D business updates

Mission critical space systems specialist Redwire has announced the acquisition of payload structure developer LoadPath. Although the exact terms of the transaction weren’t disclosed, Redwire did confirm that LoadPath’s Co-founders Greg Sanford and Adam Biskner would remain part of the newly-merged company.

Based in Mexico, LoadPath’s technology has supported over 20 space flights, including both commercial clients and government contractors such as NASA and the Department of Defense. The deal also marks Redwire’s fifth purchase this year, following the acquisitions of Made In Space and Adcole Space, among others.

“LoadPath brings market-leading capabilities to augment Redwire’s space infrastructure portfolio,” said Peter Cannito, CEO of Redwire. “We are excited to work with Adam and Greg and the LoadPath team, to leverage their impressive technology flight heritage and advance their capabilities as a part of Redwire.”

3D printer manufacturer VELO3D has formed an exclusive U.S distribution partnership with the software developer and reseller GoEngineer. As part of the deal, GoEngineer will market VELO3D’s SupportFree portfolio and provide support for its Flow software, Sapphire machines and Assure quality assurance system.

“We are pleased to partner with VELO3D to help manufacturing companies across the U.S. produce mission-critical parts,” said Ken Clayton, CEO of GoEngineer. “Metal additive manufacturing is an important piece to GoEngineer’s portfolio, and we are excited to help our customers differentiate themselves even more.”

Finally in business news, 3D printing service provider Morf3D has acquired four AMCM M4K-4 systems from modified printer manufacturer AMCM GmbH, taking its total number to eleven. The customized machines, which are based on the EOS M400, have been optimized to print large-volume parts up to one meter in height.

“AMCM is pleased to support Morf3D in their clear and targeted market approach,” said Martin Bullemer, Managing Director of AMCM. “Together with Morf3D, we’ll be able to demonstrate the stability of our technology, and support their growth in the aerospace, defence, and space markets.”

Siemens updates Parasolid software

Industrial manufacturing firm Siemens has released an update for its Parasolid geometric modelling program. The new version integrates previously incompatible facet and B-rep data formats, as well as providing greater support for mixed models, that could reduce the need for time-intensive conversion.

Additionally, Parsolid users now benefit from the introduction of face editing and rendering tools, while B-rep enhancements also provide flexibility when blending and sweeping. The updated software, which is part of the firm’s broader Xcelerator platform, has been officially launched and is available for download.

Fraunhofer ILT in EU laser initiative

Fraunhofer ILT has revealed that it will be coordinating one of the eight technology platforms participating in the upcoming EU-backed Photonics Digital Innovation Hub. The €19 million project has been set up to support SMEs in the adoption of photonic technologies, and aims to create 1000 new high-tech jobs by 2025.

During the program, which starts in 2021, 53 research centers are set to collaborate, providing SMEs with access to photonics expertise, with Fraunhofer focusing on laser-based production. Although the initiative is due to start imminently, its organizers have stated that all EU-based photonics firms are invited to participate.

“The laser-based Manufacturing platform offers SMEs central access to numerous European colleagues,” said Ulrich Thombansen, a scientist at Fraunhofer ILT. “We’ve shown many companies how to use laser-based manufacturing technologies profitably with digital thinking. We have taught SMEs to think additive.”

3D printing’s latest applications

Global engineering firm Renishaw has revealed that it is supporting Sir Ben Ainslie’s INEOS TEAM UK in the PRADA America’s Cup World Series. As the team’s official ‘precision measurement and AM partner,’ the company has contributed its engineering expertise to help build the highly-advanced racecraft.

Specifically, Renishaw has supplied products and support with position encoders, manufacturing process control, raman spectroscopies, and bespoke structural components. The additive-boosted INEOS AC75 ‘BRITANNIA’ boat, which can reach speeds of over 60 mph, is scheduled to race from December 17th-19th 2020.

“Renishaw is proud to contribute its expertise to INEOS TEAM UK to help it develop an incredibly technologically advanced boat,” said Chris Pockett, Head of Communications at Renishaw. “The UK’s bid showcases the best of British engineering and we hope the team can make history by being the first British team to win.”

Rapid Product Manufacturing (RPM) GmbH, meanwhile, has agreed to become part of the Smart Breast Prosthesis Project. The program, which is run by Victor Portes of the Figura Nova Foundation, has brought together a group of companies that are attempting to 3D scan and print enhanced breast prosthetics for cancer survivors.

One of the organization’s goals is to combine the expertise of healthcare and technology professionals, and working with its partners Materialise and Solo Lattices, the group has made recent progress. Figura Nova now aims to make the devices into a low-cost service, with a 300-patient roll-out planned for 2022.

Finishing this week’s edition with a festive flourish, James Sargent of the insurance firm Neos, has 3D printed a bauble that’s able to hold the company’s smart camera. The decorative device is both designed to help parents prevent their children from opening presents before Christmas, and to capture their favorite moments.

“I found myself inspired by our Neos customers, who are always using their smart cameras to capture wonderful things,” said Sargent. “Last Christmas, we saw so many people reenacting Father Christmas through their smart cameras to add an extra layer of magic for their children. I’ll be able to take it a step further this year!”

“During a year that’s seen so many families apart we’ve seen our customers turn to their Neos SmartCams for all kinds of things” he added. “As long as family members have access to the camera through the Neos app, they’re able to stay connected, even if they can’t be there physically.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of the Neos team’s 3D printed bauble. Photo via Neos.