In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a range of reseller deals as well as factory acquisitions, additive awards, experimental materials, far-reaching 3D printing reports and a fully-fabricated flight-ready model plane.

Read on for the most recent updates from GoProto, ORNL, EVOK3D, 3D Systems, Creaform, Markforged and more.

Farsoon and Nexa3D expand reseller networks

Starting this week with business updates, Chinese SLS and SLM 3D printer manufacturer Farsoon has signed a distribution agreement with industrial solution reseller Maha Chemicals. The deal will see Maha market Farsoon’s metal and plastic 3D printers, both in Singapore, and the rest of the Southeast Asian market.

“We highly value Maha’s solid know-how in industrial manufacturing and open attitude towards technology innovation.” says Vince Zhao, Global Channel Manager (AMEA) of Farsoon. “We are confident of offering high-quality, cost-performance, truly open Farsoon AM solutions for extended industrial customer bases in the Singapore market.”

SLA printer manufacturer Nexa3D has unveiled a spate of new reseller deals in the U.S, Mexico, Finland, Estonia, Lithuania, Latvia, and Turkey. The distributors, which include Product Development Inc, AXIOMATEK, Vossi Group Oy and Promakim, will market Nexa’s NXE400 and QLS 350 systems to clients in their respective regions.

“We are thrilled to work with these esteemed additive manufacturing companies,” said Avi Reichental, Co-founder, Chairman & CEO of Nexa3D. “I am confident that they will help us realize fast and impressive results as we approach the end of the pandemic, and refocus our efforts to digitizing the world’s supply chain in the years to come.”

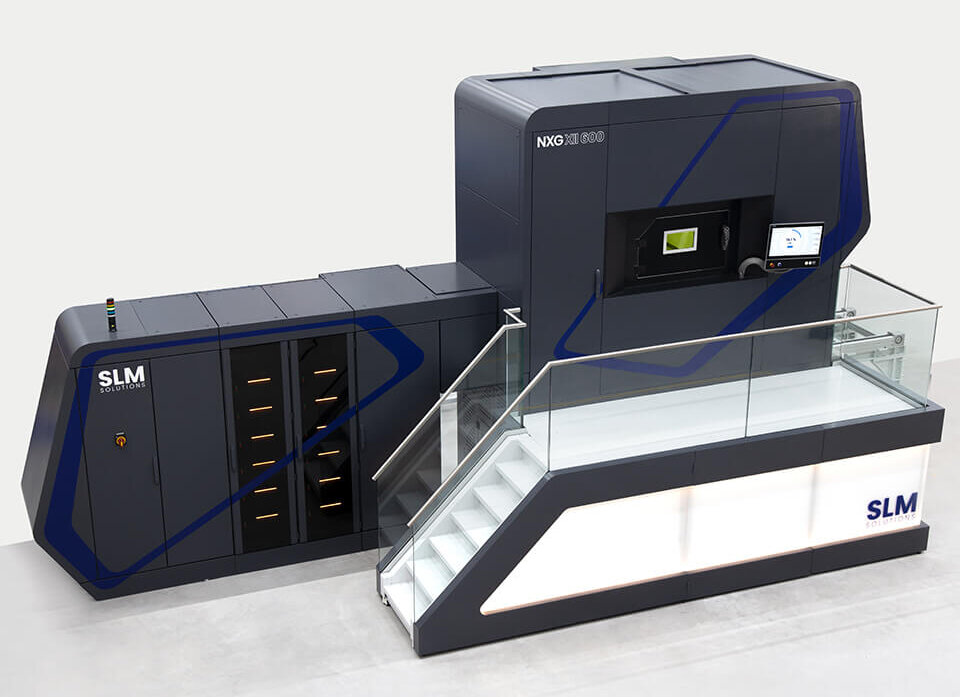

German 3D printer manufacturer SLM Solutions has signed a reseller agreement with distributor Kingsbury, that will see it market SLM’s products and services in the UK and Ireland. As part of the deal, Kingsbury will also sell the newly-launched NXG XII 600 system, which is reportedly 20 times faster than a single-laser machine.

“We and Kingsbury have a number of UK customers in common in various industries including medical, aerospace and defence, which will be excellent reference sites for prospective users,” said David Wilckens, Regional Sales Manager of SLM Solutions. “A dedicated demonstration machine will be installed in early 2021.”

Distribution company EVOK3D has announced that it has added 3DGence’s ‘INDUSTRY’ range of systems to its 3D printing portfolio. EVOK3D believes that its new machines will enable clients in the medical, mining and transportation sectors to address challenges that can’t be solved using conventional production methods.

“Our clients are telling us they want access to a broad range of materials, excellent value for money and local technical support,” said Joe Carmody, MD of EVOK3D. “With 3DGence, EVOK3D meets these needs and exceeds them with extreme polymer printing to address the material performance needs of the most demanding applications.”

Binder jetting 3D printer manufacturer ExOne has announced that the FreeFORM Technologies service bureau has installed one of its Innovent+ machines. The firm intends to deploy its system alongside its existing injection molding offering, to provide clients with easy access to affordable, lightweight metal parts.

“ExOne is proud to partner with the innovative and experienced team at FreeFORM, who will help customers tap the incredible value offered by our high-speed binder jetting technology,” said John Hartner, CEO of ExOne. “This team demonstrates how binder jetting is a perfect complement to Metal Injection Molding (MIM) operations.”

Fabrisonic and ColorForge win additive awards

Solid-state metal 3D printing specialist Fabrisonic has won an award at Oak Ridge National Laboratory’s virtual 2020 Small Business Awards. The annual event honors the companies that have made the most positive impact on ORNL’s research, and Fabrisonic was selected thanks to the custom-designed equipment it has supplied.

“We’re thrilled to be selected by ORNL as the small business of the year,” said Mark Norfolk, CEO of Fabrisonic. “This is a testament to the hard work of the Fabrisonic team and unique capabilities of metal 3D printers.”

Custom 3D printed make-up company ColorForge, meanwhile, has won the “best cosmetic innovation of the year” prize at the Cosmetics Victories awards 2020. The contest was set-up in 2015 to recognize the researchers, start-ups and SMEs conducting innovative R&D in the fields of perfume and cosmetics.

ColorForge won the prize for the design of its eco-friendly custom manufacturing and packaging system for make-up products. The company’s 3D printer can reportedly fabricate hundreds of uniquely-colored cosmetics within a single batch, taking less than five hours to do so.

“ColorForge Custom Cosmetics is a sustainable additive manufacturing process,” said John LaHood, President of ColorForge USA. “It is the first patented 3D printing process that manufactures custom color cosmetics and product casing simultaneously, sustainably and with scale. No minimums or waste.”

Software update from Sandvik Coromant

Swedish tooling system manufacturer Sandvik Coromant has partnered with 3D design software developer Autodesk to optimize the CAM element of its Fusion 360 platform. The multi-year deal will initially see the firms attempt to tackle the task of specifying cutting tools, and determining the most effective way of using them.

Currently, CAM users have to manually transfer data from tooling catalogues and input the parameters into the related software, which can be very time consuming. Through working closely with Sandvik, Autodesk aims to improve the efficiency of the print preparation phase, and reduce part lead times in the process.

“As engineers, CAM users love seeking new technologies and testing solutions, but they are often limited by the time constraints associated with CNC machining,” said Jonas Ström, Product Manager at Sandvik Coromant. “By providing them access to tool information, recommendations, we hope to simplify their process.”

GoProto acquires 3D Systems factory

Californian service bureau GoProto has announced the acquisition of 3D Systems’ Australian 3D printing facility. The company’s expansion follows its recent takeover of fellow APAC-based 3D scanning and digitizing firm WYSIWYG 3D, and makes it the largest digital manufacturer on the Australian market.

The complex in Melbourne was commissioned just 2 years ago, and as a result, GoProto has inherited several 3D Systems machines, as well as an experienced team. Through its recent investments, the company now claims to have established a position as the “largest industry 4.0 player” in the region.

“This acquisition is a significant leap forward in our growth plans for the region with an experienced management team that pioneered the introduction of 3D printing into APAC,” said Simon Marriott, a Director at GoProto. “The benefits to our manufacturing customers will be significant, as they transition to Industry 4.0 and seek to build agile supply chains.”

Novel applications from Creaform and Flite Test

Canada-based measurement system manufacturer Creaform has installed a robot-controlled measuring system for German metal assembly supplier Walter Automobiltechnik (WAT). The automotive company recently landed a contract to build the new fully electric Mini Cooper SE, and it has used its new scanner to measure the car’s complex frame.

90 percent of the part’s features could not be reworked, and would’ve caused the production line to stop if they weren’t made exactly to specification. Using the MetraSCAN 3D-R, however, WAT was able to measure the entire component within an allotted time frame, and the device’s report provided full product traceability.

“We are very satisfied with the measurement solution – it is easy to use and covers the largest possible measurement area with a high degree of accuracy,” said Tommy Laukdrej, Head of Quality Assurance at WAT. “It will definitely be used in new projects with a high degree of automation at WAT!”

Radio-Controlled (RC) aircraft distributor Flite Test has used dutch materials producer colorfabb’s LW-PLA polymer to 3D print its latest RC plane. Leveraging the foam-like material, the firm was able to fabricate the EGW80 more quickly than with conventional plastics, as it expands to three times its size once heated.

The plane itself, which features a distinctively pointed nose and integrated channels for its control electronics, was ultimately 3D printed into multiple pieces before being glued together. During test flights, the miniature aircraft proved capable of taking off, flying continuously and landing safely with minimal damage.

Material news from Chemie-Plast and Nanoe

Chemical manufacturer Huntsman Polyurethanes has extended its longstanding partnership with the plastic producer and distributor Chemie-Plast. As part of the renewed deal, Chemie-Plast will now resell Huntsman’s IROGRAN TPU pellets to filament makers that want to create high quality spools in European markets.

“We know from our work in the additive manufacturing sector, that there are some filament makers that want to add a TPU solution into their product portfolio,” said Michael Kolm, Sales Excellence Manager at Huntsman. “Our deal with Chemie-Plast enables filament makers in Europe to produce their own spools, and white label them as their own.”

Similarly, ceramics manufacturer Nanoe has signed a deal with the French 3D printer reseller MultiStation, that will see it distribute Nanoe’s Zetamix line of powders in France and North Africa. The filaments, which are composed of 50 percent plastic binders, are reportedly able to achieve a density level of over 99 percent.

“We are very happy to work with MultiStation for the development of Zetamix in the French market,” commented Guillaume de Calan, Co-founder and CEO of Nanoe.

On a more academic note, scientists from the University at Buffalo have developed a new wearable aramid/ceramic aerogel nanocomposite. During testing, the material demonstrated a low density of 0.08 g cm-3, thermal conductivity of 0.034 W m-1 K-1, and high compressive mechanical strength at 1.1 MPa.

The team found that the key to their novel process, was the in-situ crosslinking that took place between the silica pre-ceramic aerogel and its Kevlar fibers, which created an ambient pressure drying reaction. Overall, the material’s properties could lend it future applications in producing textiles for use in harsh environments.

Markforged publishes 3D printing report

Our final update comes from 3D printer producer Markforged, which has published the results of its Global AM Industry Report. Based on the feedback of 600 respondents, the survey found that 39 percent of manufacturers had scaled down their production this year, owing to a drop in client demand caused by COVID-19.

Similarly, the majority (54.6 percent) of participants said that they have had to change their strategy due to the pandemic, and only 23 percent have opted to launch products. On a more positive note, 18 percent of companies said that using 3D printing had saved them time, while 4 percent of the firms had fabricated PPE.

The full Global AM Industry Report is available to view via the Markforged website.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on the wing of an EGW80 model aircraft. Image via Eclipson Airplanes.