Though methane only constitutes around 0.00017% of the Earth’s atmosphere, the gas is responsible for 20% of the total radiative forcing created by greenhouse gases. Naturally generated by rice paddies, livestock and geysers, scientists are looking for other uses for methane and reduce its abundance in the atmosphere.

A research project from Montana State University, the South Dakota School of Mines and Technology (SDSM&T) and the University of Oklahoma, is working on a way to make methane into 3D printer materials.

Grow your own feedstock

One of the key challenges to utilizing methane is collecting and storing it in its gaseous state. As a response, the multidisciplinary team uses methanotrophs – microbes that metabolise methane – collected from natural sources such as geysers in Yellowstone National Park and Sanford Underground Research Facility in South Dakota.

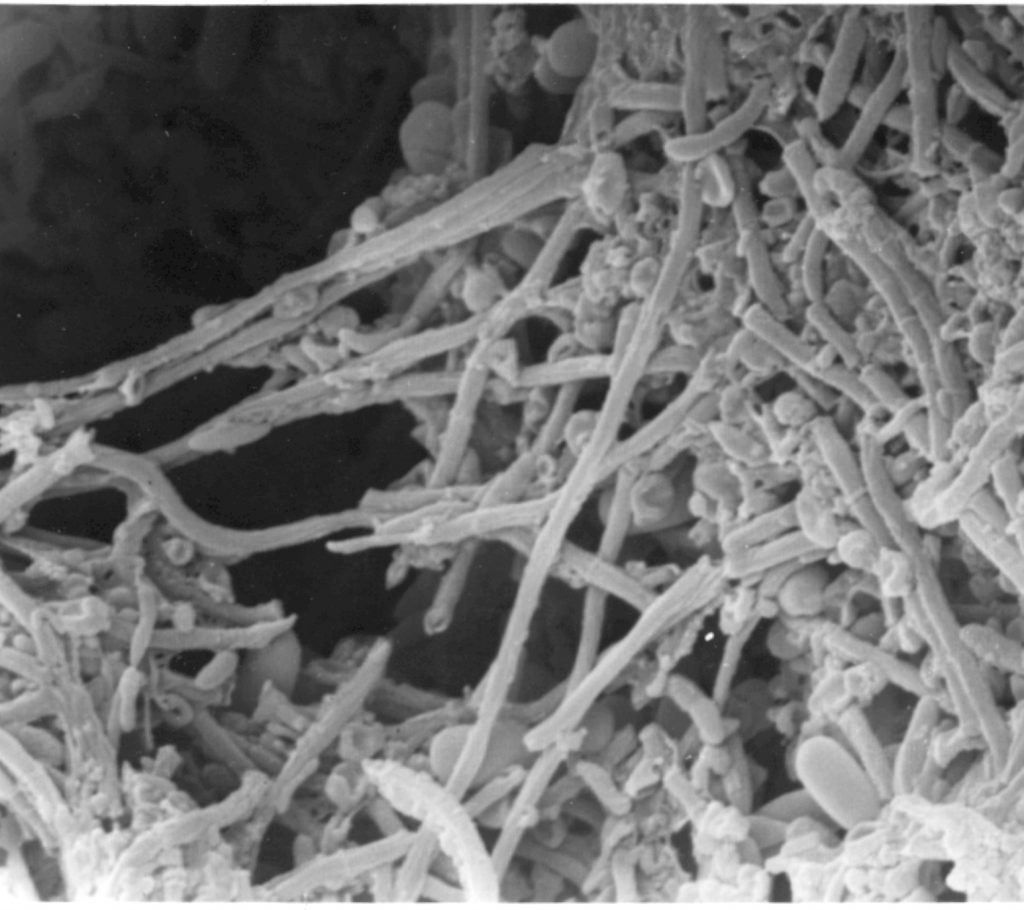

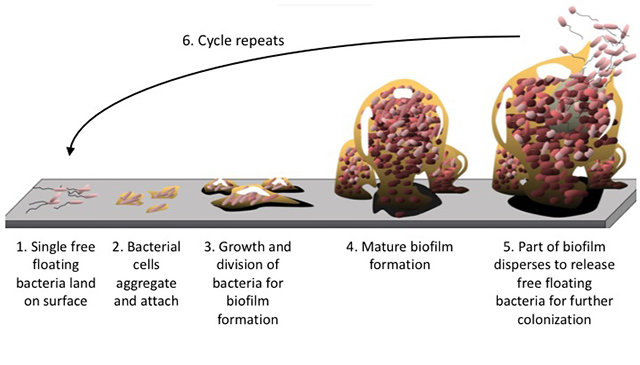

As a form of bacteria, methanotrophs grow and proliferate on a surface, eventually producing a three dimensional biofilm. By engineering this process, and encouraging the methanotrophs to bond with different molecules, biologists can turn bacteria into materials suitable for 3D printing.

Montana State professor Robin Gerlach explains, “What we are intending to do is understand their metabolism better, understand how they form biofilms slime,”

“Once we know how these organisms work we can hopefully assemble them in a way that is most productive.”

The power of 3D printing

In the Montana State led study, the goal is to make the biofilm production process similar to the way bioengineers grow artificial tissues, like skin, potentially using 3D printed sacrificial scaffolds, and directly arranging bacteria into a desired shape.

Montana State assistant professor Jim Wilking explains, “In general, there is a lot of potential for structuring biofilms in a well-controlled way.”

“The ability to spatially control multiple components and organize them into a higher order structure is really the power of 3D printing.”

Currently, the team is working to make methanotrophs into light-reactive material for SLA 3D printers “because microbes are way more robust when it comes to exposure to light.”

Wilking adds,”By controlling exquisitely the structure of the microbes you can understand structure function relationships in these systems and that basically allows you to optimize a bioproduct.”

Subscribe, like and follow to stay updated with all the latest 3D printer software, hardware and materials news. Register for 3D printing jobs here.

Featured image shows Yellowstone National Park’s Excelsior Geyser erupting at night – releasing methane and other gases into the atmosphere. Photo by Neal Herbert, National Park Service.