Researchers from the Indian Institute of Science (IISc) have developed a new abrasion-based method of producing metal powders for 3D printing.

The approach is designed to provide an alternative to atomization, the technique by which most metal powders are currently produced. In atomization, a gas or water jet is used to break up a molten stream of metal into tiny droplets, which form powder particles once cooled.

Unfortunately, despite it being the gold standard in the industry, atomization-based powder production can suffer from poor material yield, it can be cost-inefficient, and it’s only compatible with a limited number of metals. The IISc approach aims to address these shortcomings.

Priti Ranjan Panda, a Ph.D. student at IISc’s Centre for Product Design and Manufacturing, said, “We have an alternative, more economical and inherently scalable route for making metal powders, and the quality of the final powders appear to be very competitive when compared with conventional gas atomized powders.”

Metal grinding for powder production

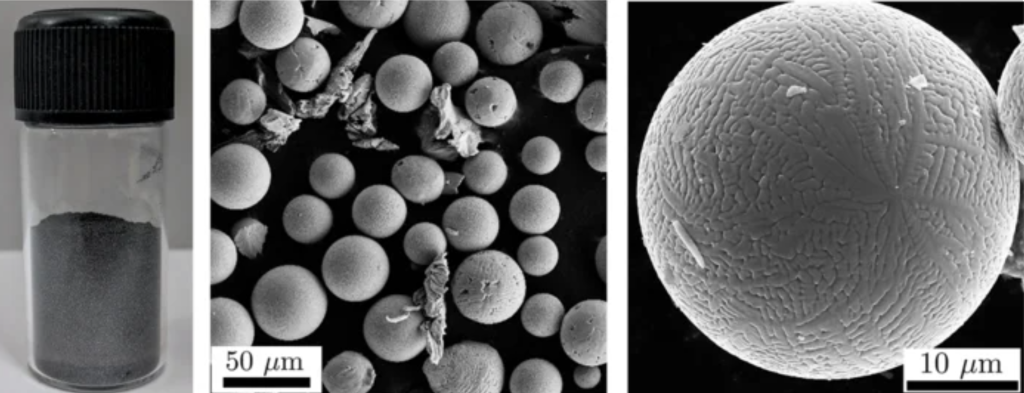

In the manufacturing sector, the waste material removed from metal grinding processes is known as swarf. These metal chippings are often in the shape of long, thin strips, but they can also include spherical powder particles.

According to the IISc team, it’s long been thought that these spherical swarf particles undergo melting during the grinding process, which is what makes them perfect spheres in the first place. As such, the researchers theorized that they could apply metal grinding, an abrasion-based process, to the production of 3D printing powders.

The study showed that melting due to high heat from oxidation does indeed cause the formation of powdered metal particles via an exothermic reaction at the surface of a metal. The researchers refined the grinding approach and optimized it to produce large quantities of steel 3D printing powder, which they claim offers comparable performance to commercial gas atomized counterparts. The grinding technique is also significantly more cost-effective than gas atomization.

The need for cost-efficient metal powders

Koushik Viswanathan, lead author of the study, states that there’s been great recent interest in adopting metal 3D printing due to the technology’s customization and design freedom benefits. However, the costly nature of today’s metal powders has proven to be a hurdle for many companies, so there’s still a need for cheaper and more accessible powders.

Harish Singh Dhami, co-author of the study, adds, “Reducing the cost of the AM process (via economical powders) can widen the range of materials in situations such as manufacturing of biomedical implants, which could become cheaper and more accessible.”

Additionally, the team believes that their abrasion-based approach also has potential in other high-performance industrial applications, including parts for aerospace engines.

Further details of the study can be found in the paper titled ‘Production of powders for metal additive manufacturing applications using surface grinding’.

The industry for powdered 3D printing materials is as active as ever. Just recently, Sweden-based materials firm Gränges Powder Metallurgy launched its very first additive manufacturing powder. Developed as part of the company’s DISPAL family of materials, AM S220 (AlSi35) is a high-performance aluminum alloy suitable for laser powder bed fusion. The material is characterized by its high stiffness, low thermal expansion, excellent wear and tear behavior, good machinability, and low density.

Elsewhere, Infinite Flex, a Germany-based developer of smart materials, recently launched what it claims to be the world’s first pure copper powder for SLM 3D printing. Dubbed INFINITE POWDER Cu 01, the material has already been successfully tested on a number of standard SLM 3D printers such as the EOS M290 and Trumpf TruPrint 1000, and is now commercially available.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows steel 3D printing powder produced using surface grinding. Image via IISc.