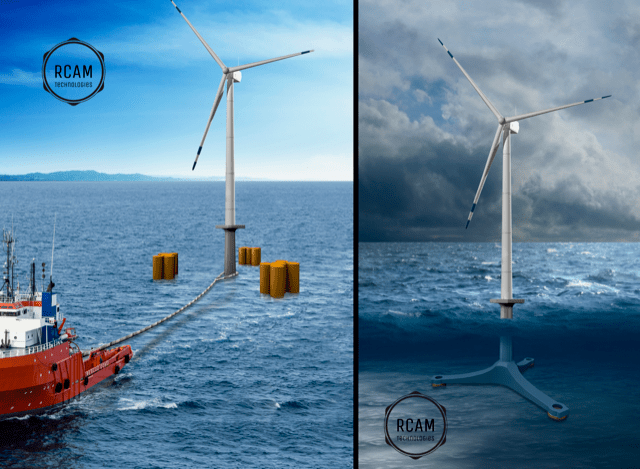

3D printed concrete startup RCAM Technologies has inked a partnership with IT service provider Accucode, Inc. Together, the partners will work to develop large-scale, 3D printed concrete structures supporting offshore wind turbines.

Part of the project will be done at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL). After initial testing, RCAM concrete 3D printing will move to Accucode’s site in Colorado Springs for further R&D by Accucode 3D and The 3D Printing Store, specialist technology divisions of the wider Accucode Inc.

Kevin Price, CEO of Accucode, comments “3D technology is in the process of disrupting how we make everything, including commercial construction. Accucode 3D and The 3D Printing Store are proud to partner with RCAM to lead the way.”

Built on decades of turbine construction expertise

RCAM Technologies was founded in 2017 by Jason Cotrell. Prior to starting RCAM, Cotrell spent over 22 years at NREL’s National Wind Technology Center, finishing his time there as Senior Engineer and Manager of Innovation and Reliability. Applying this expertise, with RCAM Cotrell seeks to leverage 3D printing in the development of land-based and offshore wind turbine towers and substructures. Targeting the construction of structures up to 20m tall such a process, according to the company, has the potential to halve the cost of conventional tall tower technologies.

A low-cost wind turbine tower 3D printing method for land has been developed and tested by RCAM in collaboration with the University of California, Irvine, with funding from the California Energy Commission Grant EPC-17-023. Concrete 3D printing for offshore wind turbines is the next step.

Earlier this year, the company was granted $250,000 by the Colorado Office of Economic Development and International Trade’s (COEDIT) Advanced Industries Accelerator program.”This grant,” according to Cotrell, “will allow us to establish large scale 3D concrete printing capabilities in Colorado and utilize NREL’s world-class testing facilities to advance our technologies.”

3D printing in construction

Concrete 3D printing is typically an extrusion-based technology, relying on a reinforced material mixture. Many different entities around the world are exploring its potential, and it has seen a marked rise in development over the past few years. A lot of work is being conducted at an academic level, including projects at the Technical University of Valencia, Penn State, MIT and the Institute for Advanced Architecture of Catalonia (IaaC). The Marine Corps Systems Command (MCSC) and the U.S. Army Corps of Engineers (USACE) have also started applying the technology for the rapid construction of temporary barracks.

For more of the latest 3D printing in construction news, subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Looking to hire additive manufacturing experts? Employers can sign up and advertise on 3D Printing Jobs here.

Featured image shows “Heavy seas engulf the Block Island Wind Farm- the first US offshore wind farm. The five Halide 6MW turbines were installed by Deepwater Wind and began producing power in 2016.” Photo by Dennis Schroeder / NREL