Canadian company PyroGenesis has announced the assembly of its first metal powder production system and production run.

The company will now spend the next four months ramping-up the process.

Based in Quebec, PyroGenesis is a company that specializes in plasma processes and is becoming increasingly re-engaged in the competitive additive manufacturing industry. The first powder produced in this run was Ti-6Al-4V, a titanium metal powder that is widely used by the 3D printing industry.

Ramping-up production

Pierre Carabin, Chief Technology Officer of PyroGenesis, explains the importance of this milestone,

The first production run not only exceeded our expectations in terms of powder quality and production rate, but it also marked both the official start of the ramp-up period and a critical step in achieving our stated goal to become a leading supplier of high purity powders catering to the Additive Manufacturing Industry.

The Canadian company was the first developers of the plasma atomization process for metal 3D printing powders in the 1990’s. However, they sold their IP to materials company AP&C which was later acquired by Swedish company Arcam, who in turn were acquired by GE.

Arcam now develops metal powders in addition to their EBM additive manufacturing machines, and it was announced earlier today a new business unit called Arcam EBM headed by Karl Lindbolm will manage the EBM division.

Lindbolm was previously CEO of Hägglund Drives and before Head of Bosch Rexroth Nordic.

There is more information about Arcam AB in this 3D Printing Industry interview with Arcam AB CEO Magnus René.

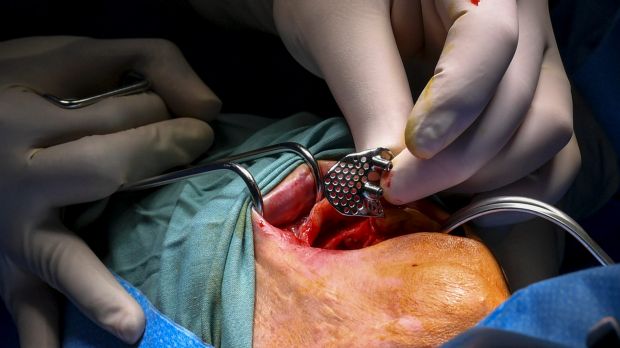

Now, PyroGenesis is re-entering the market and according to Carabin, “the System will allow PyroGenesis to produce other materials such as Titanium alloys and nickel based superalloy materials.” In this recent article, 3D Printing Industry took a closer look at the production of titanium powders with the AMES lab. 3D printed titanium has particular use in the medical industry, and this was prevalent in a recent case of jaw reconstruction.

Metal market

This announcement from PyroGenesis will intensify competition in the metal market, which should in theory lead to a better deal for end users. We took a look at this with the release of two KPMG reports on the metal additive manufacturing market.

As metal 3D printing continues to expand, more and more material companies will approach the field. American industrial company Alcoa, who are known for their aluminium production, also recently entered the market.

Furthermore, companies such as Metalysis are focusing on ways to make titanium for additive manufacturing. 3D Printing Industry attended the opening of the Metalysis Materials Development Center today, you can read our report here.

P. Peter Pascali, President and CEO of PyroGenesis, believes his company has an edge over the competitors as, “PyroGenesis is the inventor of Plasma Atomization, and has one of the largest concentrations of plasma expertise under one roof.” Pascali referred to PyroGenesis’ history to argue that the company is well placed to supply powders to an industry with, “an already serious lack of powder suppliers.” Summing up his thoughts, and those of the Canadian company, he says,

In short, we remain confident, and recent events including such a successful first powder production run, have only made us more optimistic than ever before, that PyroGenesis will quickly become a leading metallic powder supplier to the Additive Manufacturing (3D Printing) industry.

Make sure you cast your vote in this year’s 3D Printing Industry Awards where the most innovative 3D printing materials, as chosen by our readers, are to be found.

For the latest news on additive manufacturing materials, sign up to our newsletter and follow us on twitter.

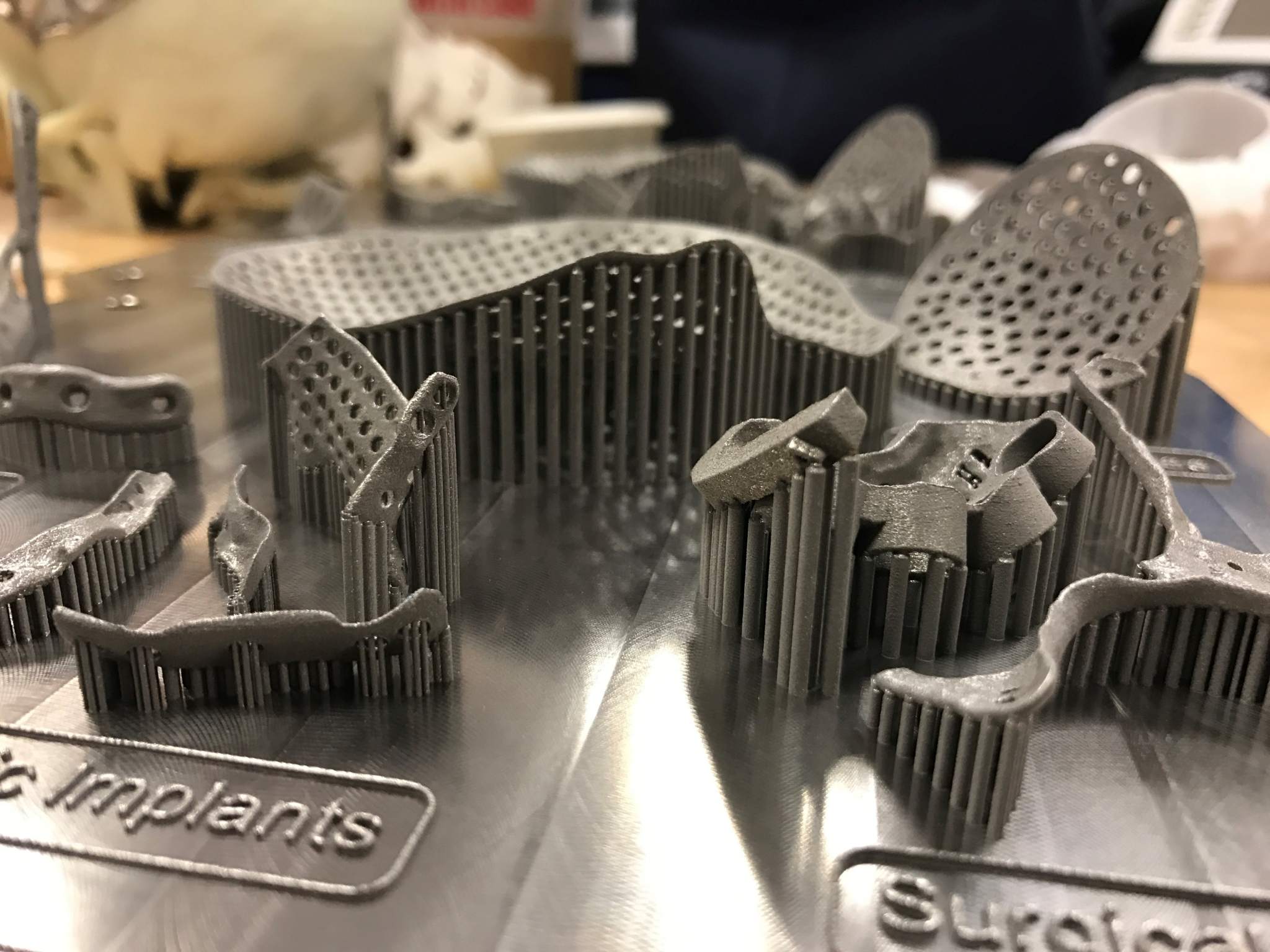

Featured image shows plasma atomization process. Photo via PyroGenesis.