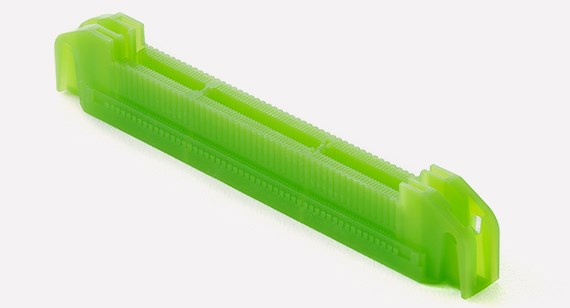

Award winning on demand manufacturing provider Protolabs has launched a new, proprietary material for SLA 3D printing. Named MicroFine Green, this resin is specifically formulated for the fabrication of small parts in high definition. Its vibrant color picks out detail, and it possesses mechanical properties akin to ABS.

According to the company, “MicroFine Green, perfectly suited to the rapid prototyping of parts with extremely fine features without compromising on strength and durability, delivers far more prototyping options to customers in industries such as medical, healthcare and electronics.”

With the addition of this material, Protolabs also provides its customers micro 3D printing capabilities without the high upfront costs of associated hardware.

“The recent launch of our new proprietary thermoset resin, created specifically for micro-resolution stereolithography, is taking 3D printing into new realms.”

Protolabs on demand manufacturing expertise

Protolabs’ foundation is in the injection molding industry, with company founder Larry Lukis developing a software to better automate the process. Now two decades into on demand manufacturing, Protolabs’ services reach across CNC machining, sheet metal fabrication, and, as of 2014, industrial-grade 3D printing services for both polymers and metal.

Though somewhat a proprietary secret at the company, the company’s software, according to a 3D Printing Industry interview with Protolabs CTO Rich Baker, is used for tasks such as “analyzing a 3D printed part or figuring out how to machine a CNC part.” Baker adds, “We’ve spent a lot on the software development side to that system work both fast and to allow us to use a different skill level of labor.” In 2017, the company bolstered its fabrication expertise with the $120 million acquisition of New Hampshire part supplier Rapid Manufacturing Group, LLC (RAPID). And, again in 2017, the company announced the that it was making its largest ever internal investment to expand the capabilities of its facility in Telford, UK.

The application of technology that earned the company a 3D Printing Industry Award was its Black Panther collaboration with PepsiCo which was voted 2018’s Creative use of 3D printing by our readers.

MicroFine Green

Valuable to the field of microelectromechanical fabrication, and medical research, micro 3D printing is an emerging sub-faction within additive manufacturing. Though there are specialized technologies for this purpose, such as two photon polymerization, these are often built to produce much finer features just hundreds of nanometers in size. The hardware for such techniques also has an RRP within the region of €150,000. By comparison, the objects produced using Protolabs’ MicroFine Green material are slightly larger than this, measured in microns instead of nanometers, which can be compared for scale to the width of a human hair (50 microns/μm).

MicroFine Green can only be 3D printed using Protolabs-modified 3D Systems Viper machines. When processed using this equipment, it is capable of producing a layer thickness of 25μm with features as small as 70 μm. Akin to the properties of ABS plastics, the material has a tensile modulus of 2,100 MPa, flexural strength of 74.3 MPa and Shore D 85 hardness.

For post-processing, solvents are used to clean the micro parts, then they are fully cured with UV light. Grit blasting can also be used if the parts and features aren’t too small. Already, the material has been used by a select number of Protolabs customers. One testimonial from an unnamed Swiss precision industry firm, states, “I am extremely impressed by the results achievable with this material. We produce extremely precise parts and prototyping for design iterations has always been an issue, both technically and from a cost perspective. I am glad to finally have such a great option at hand.”

For more of the latest 3D printing materials releases subscribe to our newsletter, follow us on Twitter and like us on Facebook. Visit 3D Printing Jobs for new opportunities in your area.

Featured image shows sample parts 3D printed in MicroFine Green. Photo via Protolabs