Prodways Group, a French 3D printer producer and service provider, has announced a series of 3D printer sales to major chemical companies for R&D and manufacturing applications. The company has sold a selection of its selective laser sintering machines to DSM, BASF and an unnamed French chemical company, including its ProMaker P1000 and ProMaker P2000 ST 3D printers.

The chemical companies have acquired 3D printers from Prodways for the purpose of research and development, parts production and material testing. By bolstering its relationships with longtime material suppliers, Prodways states in a press release that the sales are indicative of “the growing importance of 3D printing for advanced applications at industrial scale.”

High-temperature SLS 3D printing

Germany-based BASF, the largest chemical producer in the world, and already an owner of the ProMaker P1000 printer, has been a strategic partner of Prodways since 2016. In that year Prodways began distributing its new ProMaker P4500 series with a high-temperature configuration to process BASF’s Ultrasint PA6 – X028. BASF has now purchased for new plastic SLS 3D printers to aid the company’s R&D output and parts production. Recently, BASF extended its hold within the 3D printing industry with its acquisition of 3D printing service bureau Sculpteo.

DSM is also a longtime partner of Prodways, having acted as the company’s material supplier. Additionally, DSM has used Prodways’ ProMaker P4500 3D printer to print its new PBT powder Arnite AM1210 for selective laser sintering, a material suited to the electronics and electrical industries thanks to its electrical, mechanical and flame-retardant properties. Prodways sold two of its ProMaker P2000 ST 3D printers to DSM, allowing the company to test its powders for high-temperature SLS 3D printing.

Finally, Prodways has also sold one of its ProMaker P1000 3D printers to the unnamed French chemical company, which will use the system to develop and test its products. Prodways explains that the acquisition of its 3D printers by leading firms in the chemical industry allows for the mutual exchange of expertise between their respective domains.

Prodways 3D printer developments

The ProMaker P1000 3D printer was released by Prodways in 2016. Equipped with a 300 x 300 x 300 mm build platform, the system is geared towards the production of plastic parts using SLS 3D printing technology. Last year, the French Army integrated two ProMaker P1000 3D printers into its operations, in order to validate the advantages of 3D printing for manufacturing spare parts in real conditions.

The ProMaker P2000 ST is a system geared towards high temperature (up to 280°C) SLS 3D printing. This makes it capable of processing materials like PA66 or PPS, for direct use applications and advanced research.

In 2019, Prodways also released two additional 3D printers: the P1000 X, and DLP system, named the SolidscapeDL. The P1000 X improves upon the formula of the ProMaker P1000 with increased size and speed. The SoldiscapeDL on the other hand, developed through Prodways subsidiary Solidscape, is the first system within the company’s range using DLP technology and is aimed towards the jewelry market.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

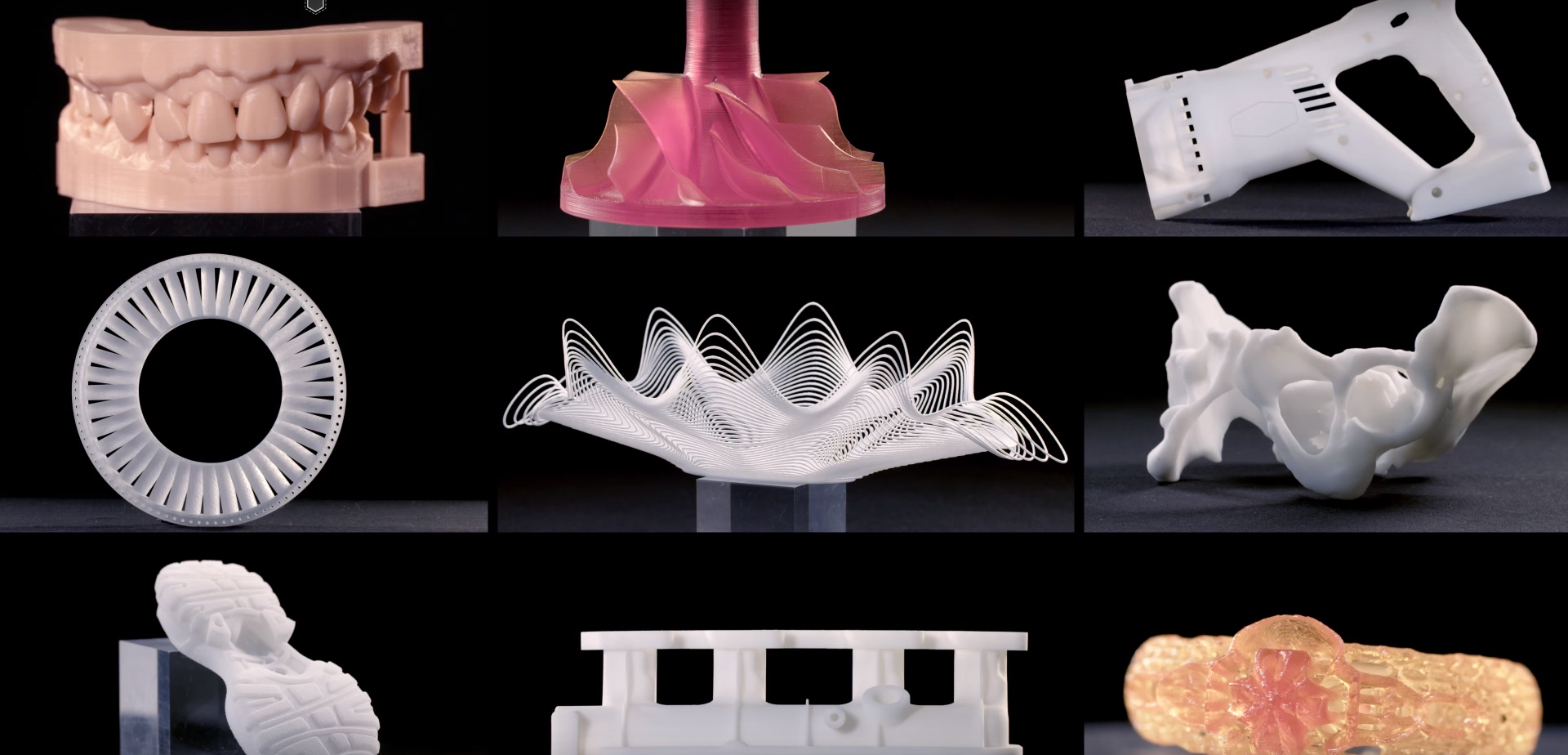

Featured image shows Prodways high precision 3D printing. Photo by Michael Petch.