In the first 2020 edition of 3D Printing Industry Sliced, our news digest, 3D Systems has entered into the culinary market with a new 3D printing system; materials to additively manufacture semiconductor devices are explored, and liquid 3D printed footwear formed in a gel bath is the latest application of MIT’s Rapid Liquid Printing method.

Also in this edition are updates from Saratech, Autodesk, Airbus, the University of Cambridge and Protolabs.

Acquisitions, partnerships, and 3D printing in the culinary market

Brill, Inc., a CSM Bakery Solutions company, has introduced a full-color, professional-grade culinary 3D printing system known as the Brill 3D Culinary Studio. Powered by 3D Systems, this 3D printer allows chefs to create edible culinary figurines and embellishments. The first 3D Culinary Studio will be installed this summer.

Saratech, a Californian provider of manufacturing solutions, has announced the acquisition of the 3D Printing sales sector of TekPro Group, machinery specialists based in Fontana. This acquisition aims to boost technical and sales resources within Saratech’s Additive Manufacturing business.

Elsewhere, Missouri-headquartered Metaform has acquired B3 Innovations’ Pico and Pico Hybrid hotend IP and is launching the Pico Hybrid hotend later this year.

A team from Cambridge University’s Department of Engineering has received funding from the Engineering and Physical Sciences Research Council (EPSRC) to commence a three-year research program that will use holography to control the distribution of laser energy in 3D.

“Rather than using a single beam with a scanning mirror, we can use multiple beams at the same time,” stated Tim Wilkinson, professor of photonic engineering and leader of the project. “We can build up our structure in a more three-dimensional way, which allows us to control things like thermal stresses.”

Medical and materials research

BiologIC Technologies, a Cambridge-based medical start-up, is developing an automation platform with affordable, application-specific cartridges to develop and run advanced cell therapies.

Nick Rollings, a co-founder of the company, explained, “We’re hoping to develop an ecosystem—a standardized platform on every bench and in every lab. If you look at the computing revolution, the PC enabled that, but there’s nothing like that in life sciences. Our differentiator is using 3D printing to fabricate systems in a new way.”

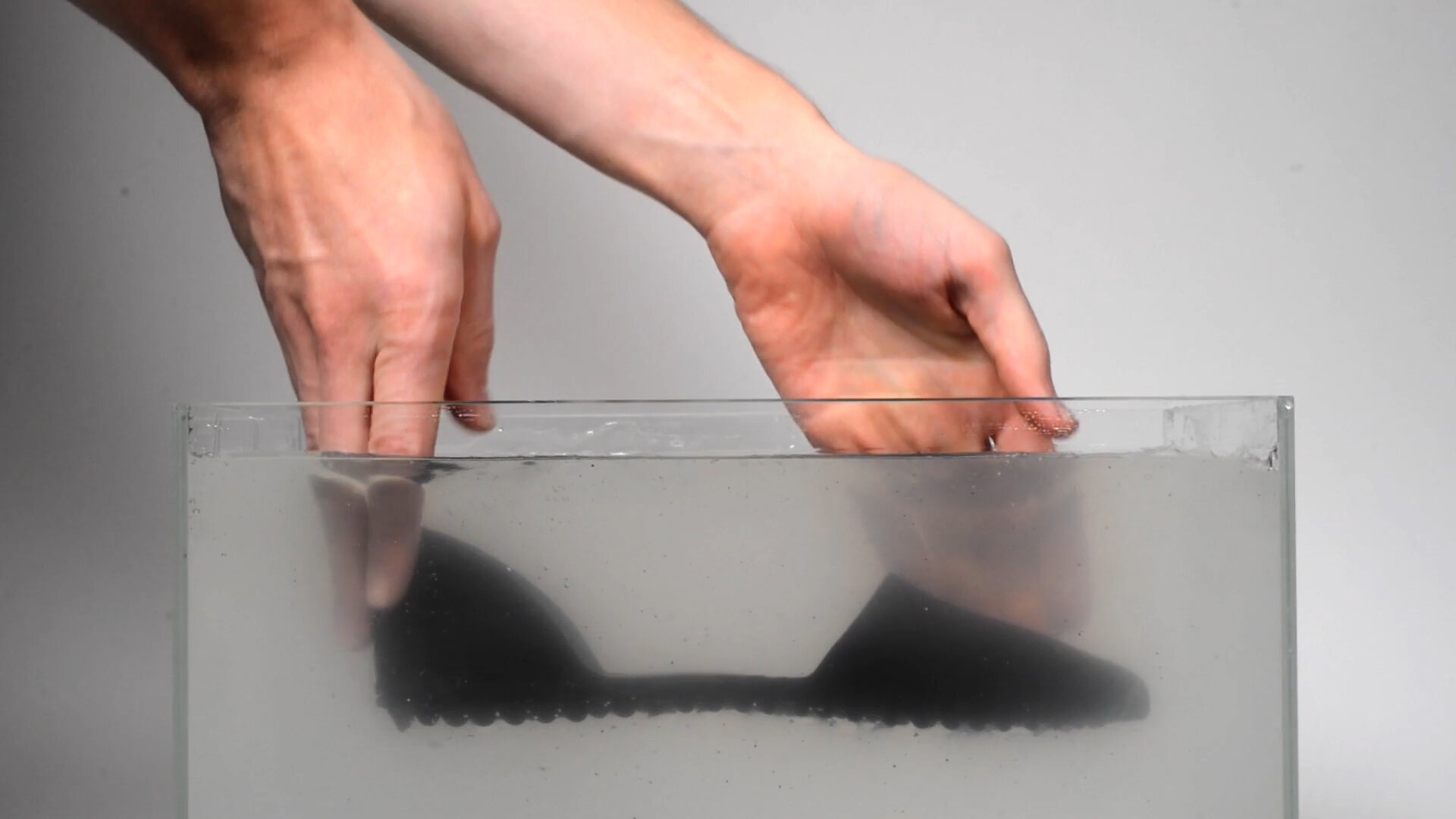

Elsewhere, Native Shoes, a Canadian footwear manufacturer, has partnered with Emily Carr University of Art + Design, Vancouver, and MIT’s Self-Assembly Lab to create Liquid Printed Natives, a flat shoe additively manufactured in a clear gel bath using the Rapid Liquid Printing method.

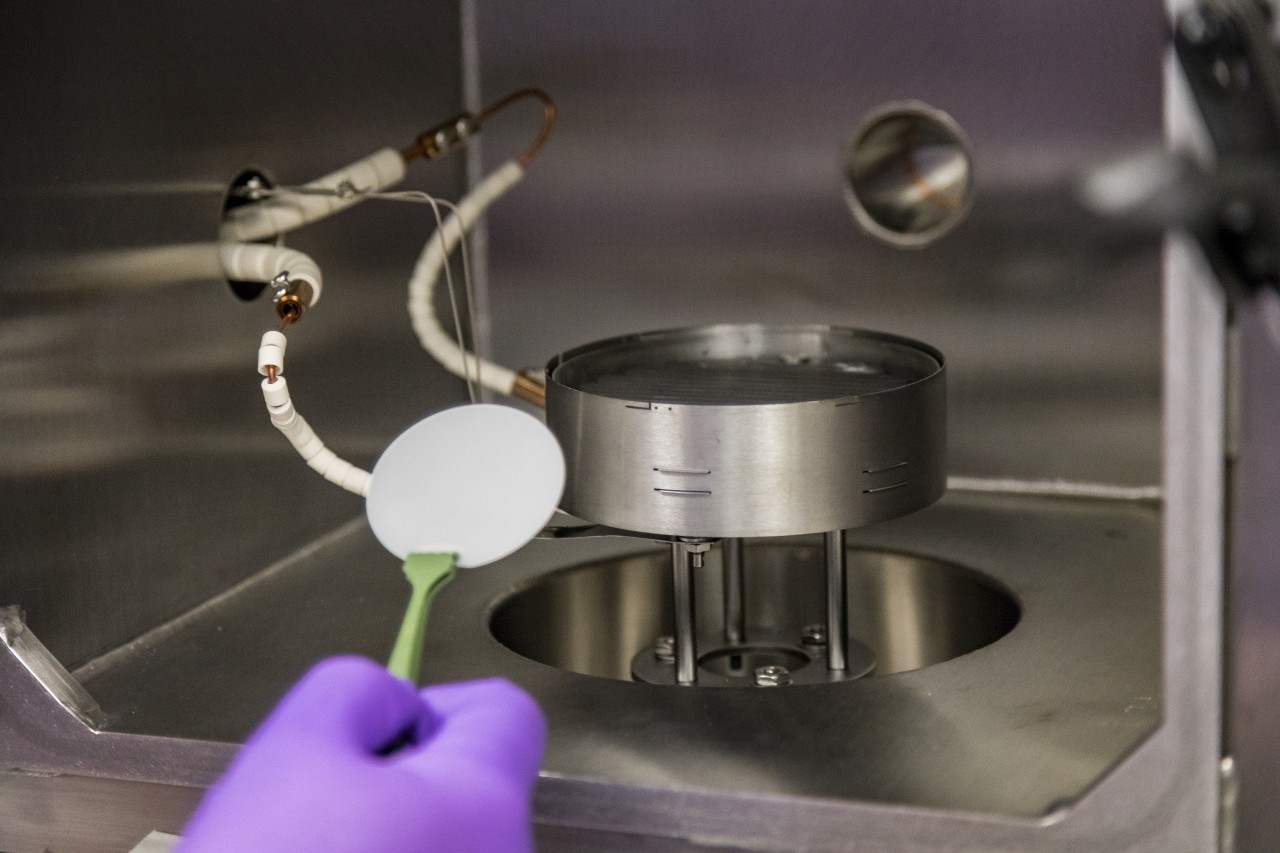

A team from the Johns Hopkins Applied Physics Laboratory (APL), in Laurel, Maryland, has created a novel method to 3D print gallium nitride (GaN) — a material used to produce semiconductor power devices, radio-frequency components, and light-emitting diodes. The research, “A pathway to compound semiconductor additive manufacturing,” was published recently in MRS Communications.

The Cool Idea Awards

On-demand digital manufacturing provider Protolabs has announced that the winner of the latest Cool Idea Award as Wayzn, the California-based company behind the Wayzn Slide, a device that remotely controls doors to let pets in and out of the house. It was developed using SLA components.

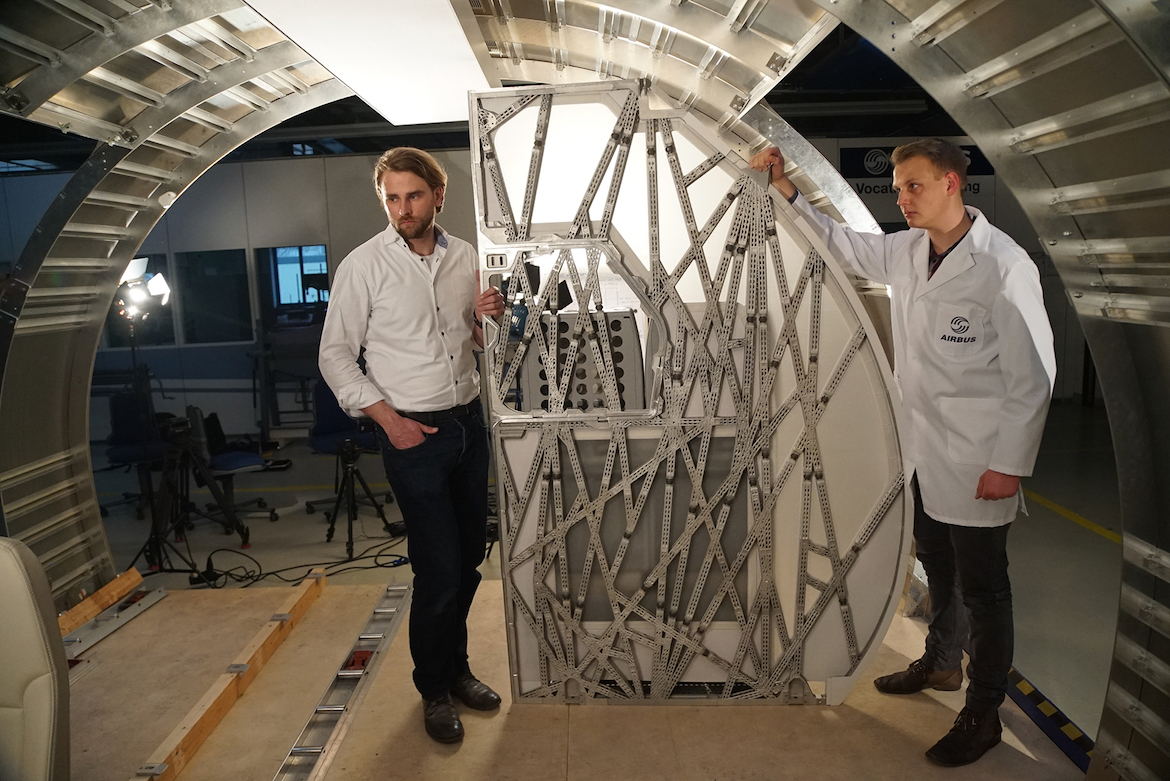

Autodesk, Airbus, and generative design

Autodesk, an award-winning American software company, is collaborating with International aerospace giant Airbus, to reimagine multiple structural aircraft components. Last month at Autodesk University in Las Vegas, Nevada, Airbus emphasized the importance of generative design for such advanced parts. Bastian Schaefer, Airbus Operations, stated:

“Generative design is helping us create a more sustainable architectural design that better accounts for critical human factors and work conditions. It has also expanded our way of thinking and our approach to design by overcoming preconceived notions and blind spots. Whichever design we choose, we know the factory will function more efficiently and will be less costly to build.”

For the latest 3D Printing Industry news, subscribe to our 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows the Sliced logo over the Liquid Printed Natives in the gel bath. Photo via MIT Self-Assembly Lab.