German metal 3D printer manufacturer SLM Solutions has announced orders valued at €67.7 million for 2019, a 21% growth compared to 2018. Meddah Hadjar, CEO of SLM Solutions, comments:

“The double-digit growth in order intake in 2019 under the current market conditions demonstrates that the multi-laser technology is critical for additive adoption in all market segments.”

“We continue to work on addressing organizational gaps and positioning the company for long-term growth. Our interest is the long-term potential of SLM Solutions’ technology, however, the team has worked hard and achieved great progress in the second half of 2019.”

Increasing metal additive manufacturing technologies

According to Uwe Bögershausen, former CFO at SLM Solutions, the company’s order intake for the first quarter of 2019 decreased from the year before standing at €3.5 million from €8.9 million. This was attributed to a negative EBITDA trend is a consequence of the lower revenue which caused SLM Solutions to adjust its forecasts.

Nevertheless, Hadjar states that with the momentum of the second half of the year, “We believe that we have taken the right first steps towards a long-term successful future for SLM Solutions.” This is evident as the fourth quarter of 2019 recorded an order intake of €29.5 million, representing 100% growth year-on-year.

The company also welcomed Sam O’Leary as its new Chief Operating Officer since December 1, 2019, and Frank Hülsmann, as the new CFO as of January 1, 2020, who are working to accelerate the demand for SLM systems. Hadjar added, “[They] are working together with full dedication to position SLM Solutions as a market leader in our industry.”

SLM Solutions, applications & research

Contribution to the company’s momentum in the second half of 2019, SLM Solutions entered into a collaboration with multinational manufacturing conglomerate Honeywell. This partnership aims to qualify new additive manufacturing parameters that enable printing at increased thicknesses. As such, SLM Solutions will be providing the hardware and materials for Honeywell to qualify.

Moreover, CeramicSpeed, a supplier of ceramic bearings for cycling and industrial applications based in Denmark, and the Danish Technological Institute (DTI), utilized an SLM 500 metal additive manufacturing system to develop a 3D printed pulley wheel for professional cyclists.

The 2019 annual report of SLM Solutions Group is set to be published on March 26, 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

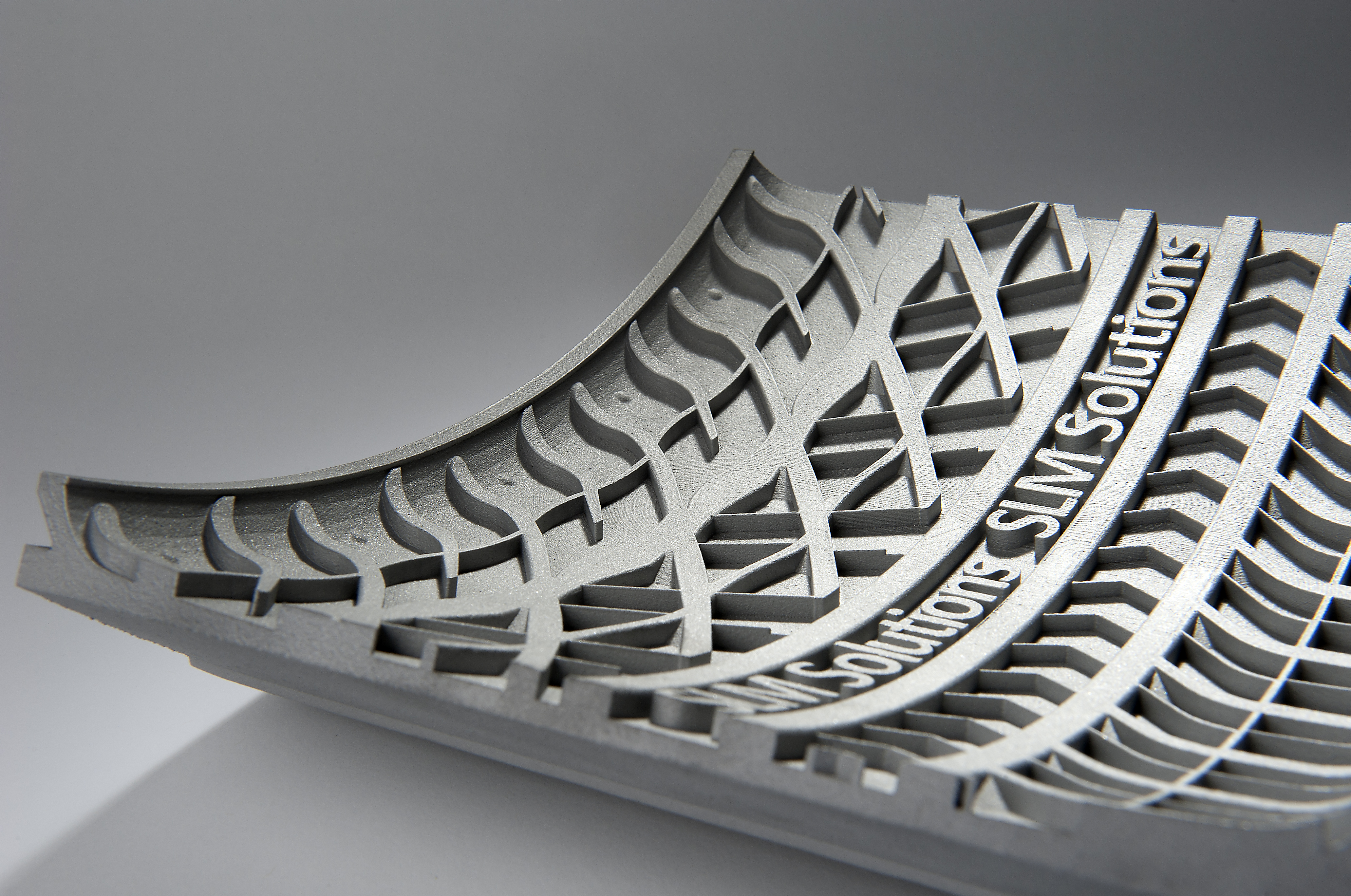

Featured image shows SLM Solutions’ labs. Photo via SLM Solutions.