Geometric deep learning specialist Physna has raised $20 million in Series B funding which it will use to grow its team and further develop its 3D printing software offerings.

The funding round, led by Sequoia Capital with participation from the leader of Physna’s Series A funding round, Drive Capital, brings the total funds raised by the company to $29 million.

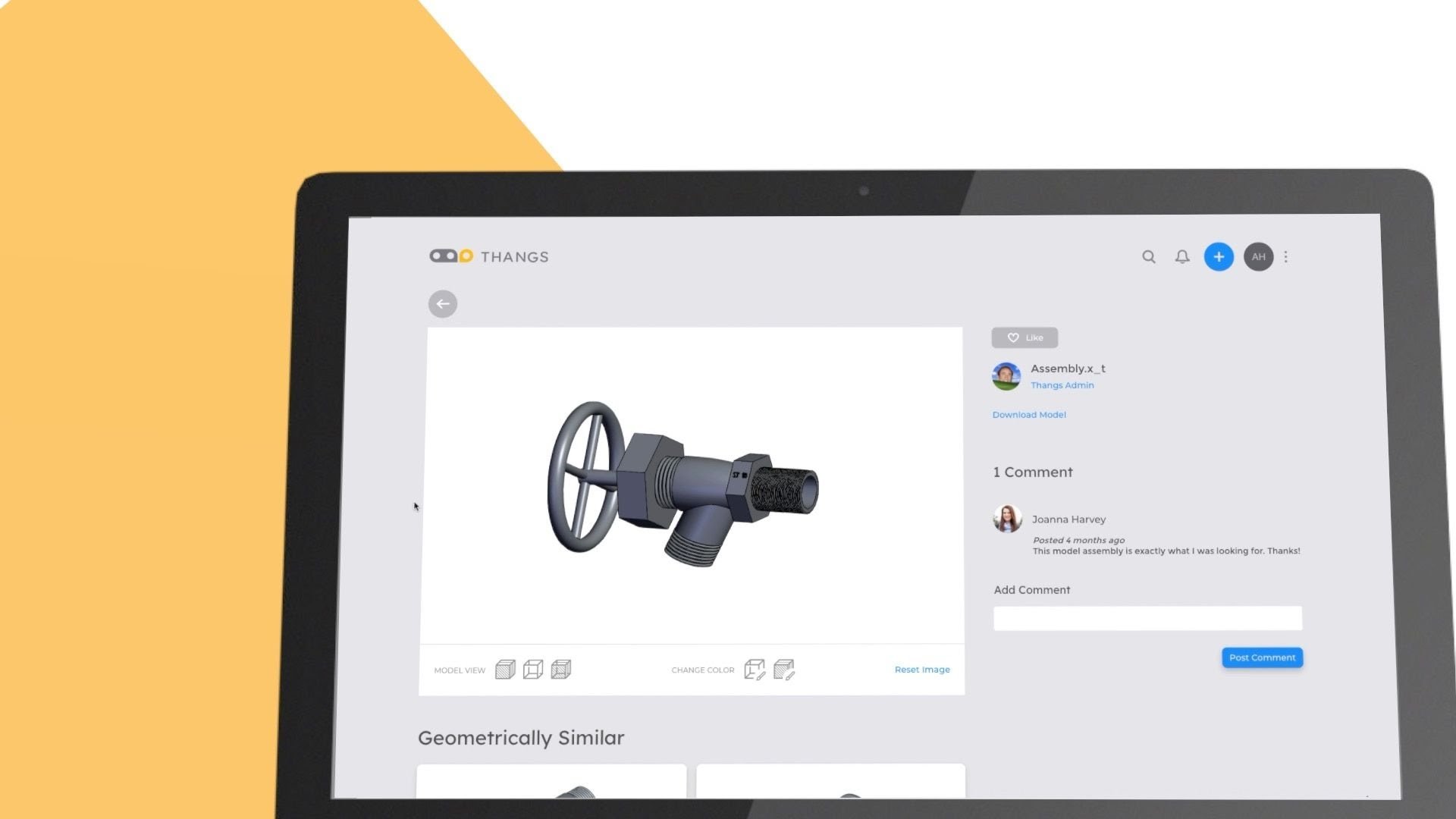

The firm also announced a major update to its geometric search and collaboration engine, Thangs, which allows users to search with 3D models rather than relying on text. The software can now support assembly files from virtually any platform, bringing the company one step closer to making 3D models accessible to all.

“Physna has enabled a quantum leap in technology by allowing software to truly understand physical 3D data,” said Paul Powers, CEO and Founder of Physna. “By merging the physical with the digital, we have unlocked massive and ever-growing opportunities in everything from geometric search to 3D machine learning and predictions.

“Having both Sequoia and Drive endorse this next-generation of search and machine learning helps Physna empower even more technical innovations for our customers and the market as a whole.”

Teaching computers to “think” in 3D

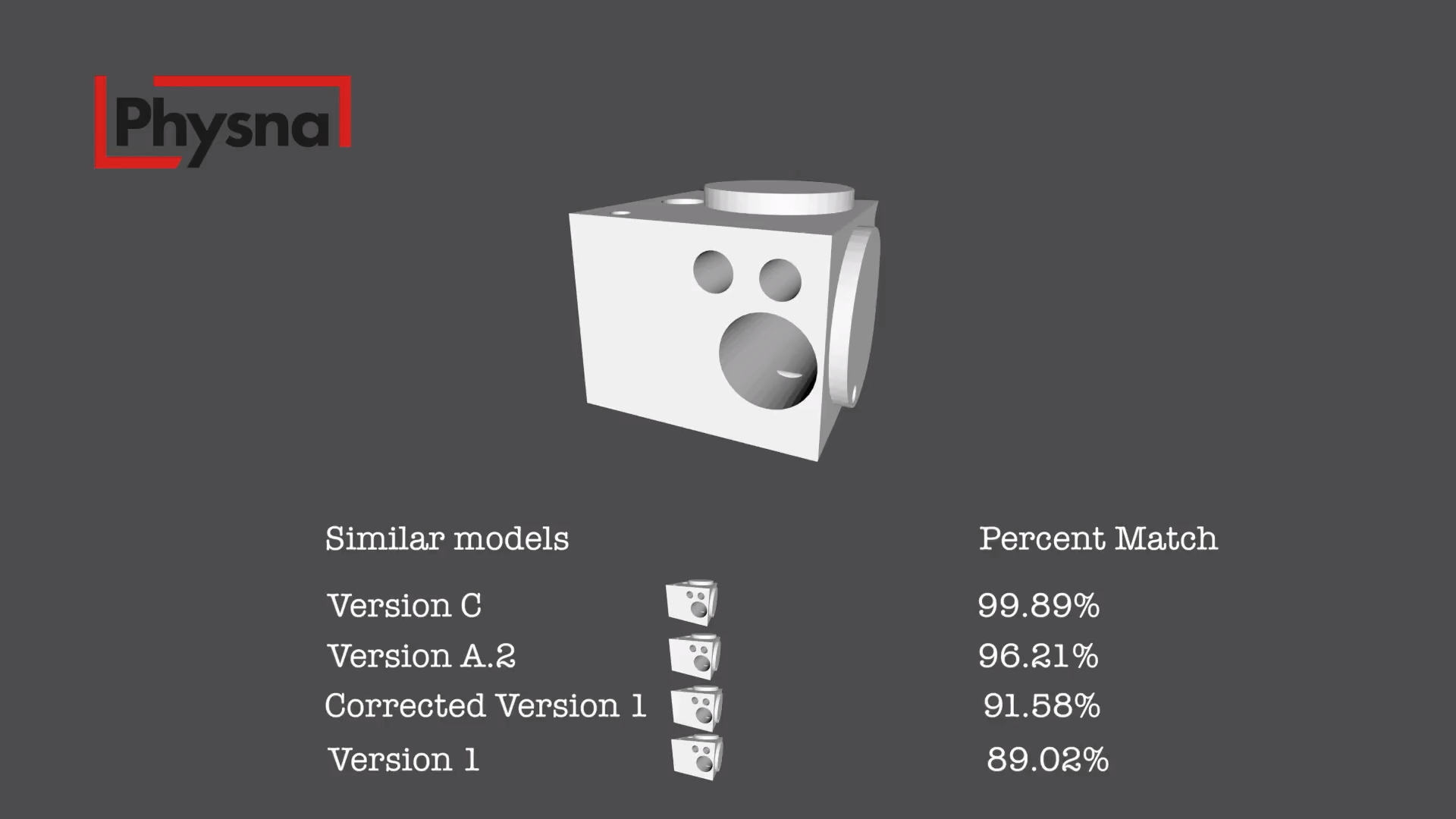

Founded in 2016, Physna is a geometric search engine designed with the goal of increasing the efficiency of CAD design and 3D printing. The engine uses geometric deep learning technology and mathematical analyses to codify 3D models into data that can be understood by software applications, enabling users to find new 3D models by searching with predefined 3D objects, partial models, or geometric measurements.

The engine’s proprietary algorithms can evaluate, compare, and analyze the similarities and differences between 3D models, and can reportedly sift through millions of models in seconds. The search engine can also be used to see whether standards or custom compliance for the 3D files will be met before printing.

Physna completed a Series A funding round in 2019, raising $6.9 million which it ploughed into further developing its search engine and increasing the adoption of its technology. The firm has previously partnered with the likes of Siemens, NASA’s Space Camp, PTC, Oracle, and leading universities such as Purdue University, to deploy its geometric search engine software.

With its latest funding round under its belt, Physna is now seeking to further the development of its search engine in order to meet increased demand, and will also grow its team. As part of the funding agreement, Sequoia partner Shaun Maguire will join Physna’s Board of Directors.

“Paul and the Physna team have developed a breakthrough platform that enables intuitive search of 3D models for the first time,” Maguire said. “With the amount of 3D data in the world about to explode, Physna will be the way this data is organized and accessed – ultimately becoming the GitHub for 3D models.”

The 3D world’s Google x GitHub crossover

Launched in August 2020 as Physna’s first open product, Thangs has been hailed as the 3D world’s most powerful geometric search engine. Thangs uses deep learning algorithms at the core of Physna’s enterprise offerings to index 3D models based on the polygons that make up their volumes. Through the platform, users can search based on the object’s physical properties, measurements, and features and receive predictions about its function, cost, materials, and performance.

Since its launch, hundreds of thousands of people have used the platform to improve their workflow from product design to 3D printing. The Physna team has now added significant updates to the software, including support for more complex content types beyond simple 3D models. Thangs can now facilitate assembly files from almost any platform, allowing users to upload files ranging from massive assemblies to sub-assemblies and components.

Thangs’ light version of Physna’s core algorithms analyses and suggests alternative ways of building models, helping users to see how parts fit together. According to Physna, this update further opens up the accessibility and usability of 3D models to a wider range of people, regardless of background or circumstance.

Machine learning in AM

With recent patent data identifying machine learning as the fourth fastest-growing technology of the past year, it is no surprise that it is becoming increasingly common within additive manufacturing, too.

Machine learning has been previously utilized within the sector to enhance 3D printing quality control, improve the efficiency of metal printing, and detect 3D printer failures. In 2019, 3D printing software developer 3YOURMIND was awarded €1.3 million to integrate machine learning into its 3D printing workflow.

More recently, researchers from New York University’s Tandon School of Engineering successfully used machine learning to expose vulnerability behind 3D printed composites, while Argonne National Laboratory and Texas A&M University teamed up to develop an innovative new approach to detect defects in 3D printed parts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Physna’s solution in the workplace. Image via Physna.