Headquartered in Cincinnati, Ohio, Physna LLC is a 3D modeling software developer. Its patent-pending and eponymous technology allows users to compare and analyze thousands of 3D models for the purpose of quality control and automated inspection.

Already a solutions partner for Siemens Product Lifecycle Management (PLM) software, Physna expedites the product development process, allowing more faster and more reliable rapid prototyping.

Paul Powers, a law graduate of Heidelberg University, Germany, Astronomy and Astrophysics alumni of Harvard and serial entrepreneur, founded Physna in 2015.

Undoubtedly holding tremendous value for industrial additive manufacturing, 3D Printing Industry interviewed Powers to find out more.

In layman’s terms, what is Physna?

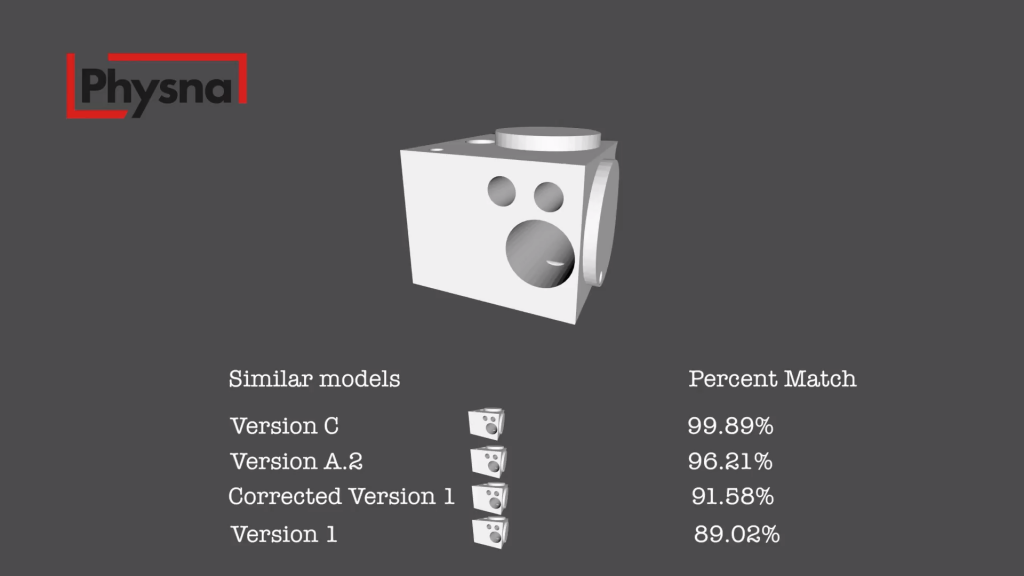

Paul Powers: Physna is short for “Physical DNA”. The company focuses on enhancing engineering through feature search, standard compliance, shape search, model comparison, part extraction, etc.

The technology is also able to compare models for quality control and automated inspections (e.g. cell tower inspection using drones with scanners).

How does Physna work? Is the database of 3D models used internal? Or company specific?

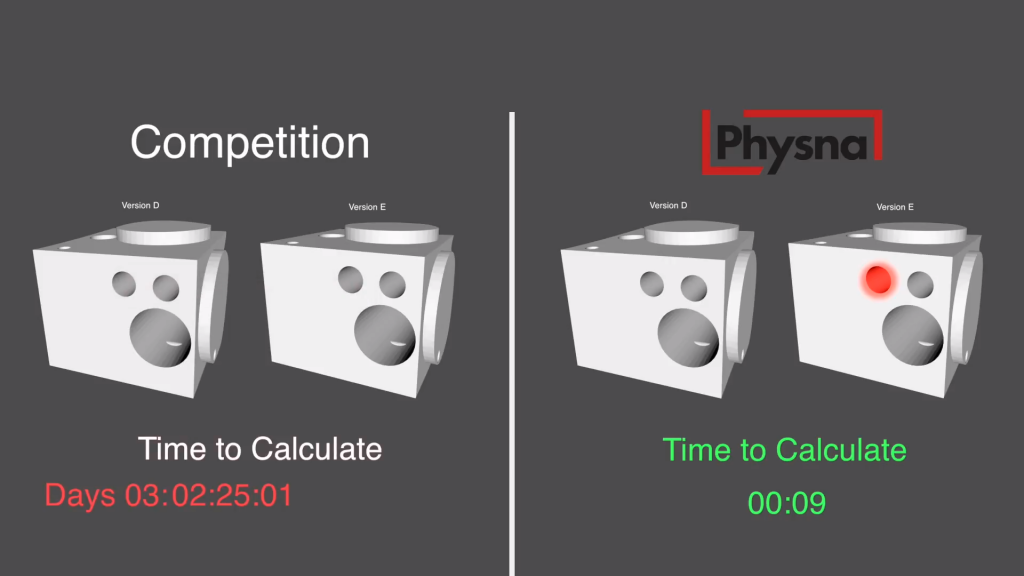

PP: Our software uses proprietary algorithms to evaluate 3D models, compare them and analyze them more accurately than any other technology.

Each user’s database is secure and we do not share data from one to another. So it’s more a series of databases than a centralized one. We do have our own database of publicly available files that we pull from the internet though and that is used to enhance our machine learning / artificial intelligence.

One of the founding principles of Physna was to develop a software that could help additive manufacturers prevent theft. Is this still a feature of the software?

PP: Yes, Physna can still be used to prevent theft, but that is not its primary application.

Physna software does not automatically search for theft, though the user or partner company (e.g. a CAD company or slicer software for 3D printing) can utilize it for that purpose. That just requires special setup.

How does Physna software compare with other such services on the market? For example, 3YOURMIND.

PP: Physna is very different from other services. It specializes in feature comparison, ensuring standard compliance throughout an organization, saving time when designing new models, and automating the creation of a digital thread throughout the lifecycle of a product.

It is not primarily used to optimize 3D printing settings like 3YOURMIND – that is a very different type of service.

For more exclusive interviews and news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Search and post 3D Printing Jobs for new talent in sofware, engineering and more.

Featured image shows Physna’s solution in the workplace. Image via Physna