Recently Altair, a 3D design and simulation software developer based in Troy, Michigan, has launched a Startup Program. A three part process, the program gives eligible business access to its suite of solutions for digital design simulation, computer aided engineering (CAE), cloud computing and the Internet of Things.

Innovation & qualifications

The Altair Startup Program tailors to the specific needs of fledgling businesses. It allows full-featured access to all Altair software titles, instructor lead training courses, expert consulting support, and an extensive amount of co-marketing opportunities to help build startup brand awareness.

“The startup community has always been at the forefront of innovation in new and high-growth markets of shared interest,” says Michael J. Kidder, SVP of Corporate Marketing of Altair.

“This program provides a powerful vehicle for Altair to connect more directly with hardware startups to help mitigate product performance and financial risks early, realize a successful exit and cost-effectively scale for growth with Altair’s open-architecture simulation solutions.”

In order to qualify for the startup program, a company must be a privately owned venture that was founded less than four years ago, and has revenue of less than $10 million per year. However startups that do not meet the Altair Startup Program qualifications may still apply for other incentive programs that Altair offers for small and medium businesses.

3D printing needs

Generative design, performance optimization, casting, forging, and with design for additive manufacturing can all be catered for by Altair’s software platform. As previously reported, Altair corporation has continually expanded its 3D printing interests.

Last year it added Additive Works’ Amphyon program to its software suite. Now with Amphyon (a program designed to optimize the design of metal parts of selective laser melting), companies are able to replace experimental driven development with efficient and cost-effective digital simulations. The company also has an existing partnership with Airbus APWorks which gave customers access to custom 3D printed parts to fit their various needs.

In summary, Altair’s program could be extremely beneficial to the fresh startups in need of assistance. In addition its long list of accessible software would allow for more efficient production of 3D printed parts which in turns would result in reduced costs and waste for the startups.

Want to stay up to date on 3D printing news like this? Then sign up to our 3D Printing Industry newsletter. Likewise you can follow us on Twitter or like us on Facebook. Looking for a career in engineering? Apply for 3D Printing Jobs today.

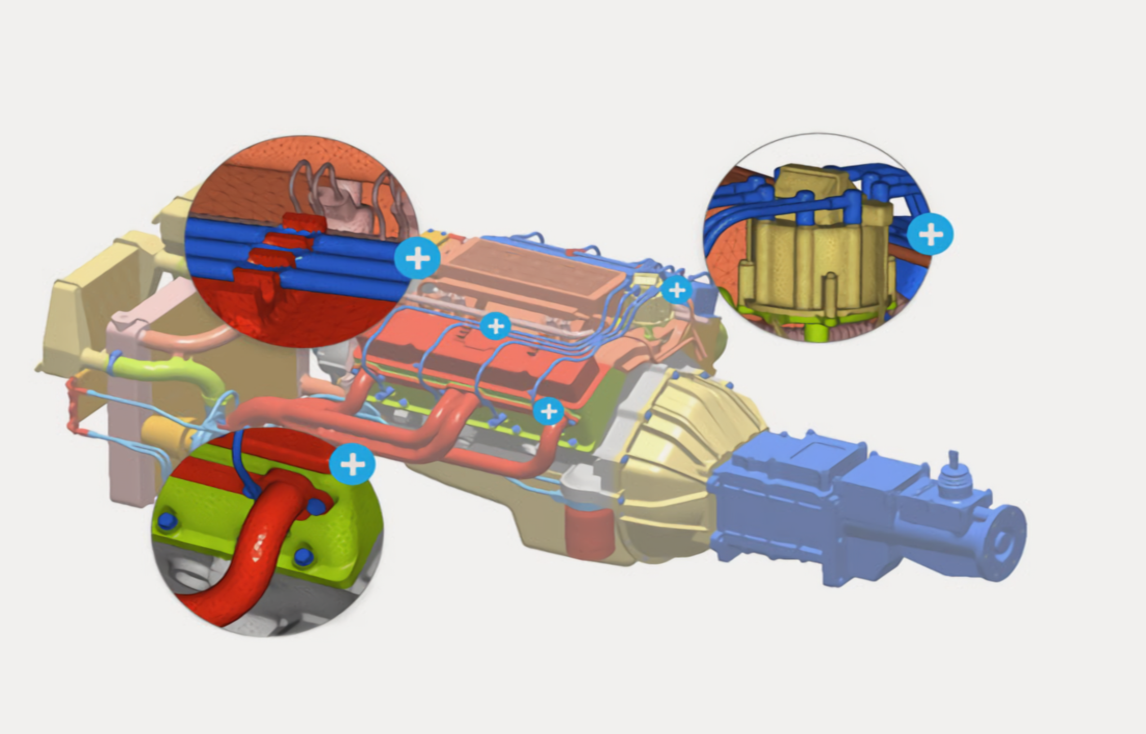

Featured image shows a software rendering of a manufactured part in order to display the efficiency and endurance of the part. Photo via Altair.