PartWorks, a rapid digital manufacturer of low volume metal, plastic and wood parts, is helping inventors design, prototype and manufacture their products, successfully bringing their ideas to life. The company serves customers in industries ranging from aerospace, automotive and energy to industrial and medical. Now, inventors like Joe and Mollie Herzberger of Wicked Wakesurf Designs are benefiting from PartWorks’ capabilities in 3D modeling and design using Solidworks, 3D Laser Scanning using Faro scanners, and manufacturing of metal and plastic parts. By relying on them for production, entrepreneurs can focus on the important things like growing sales and expanding their business.

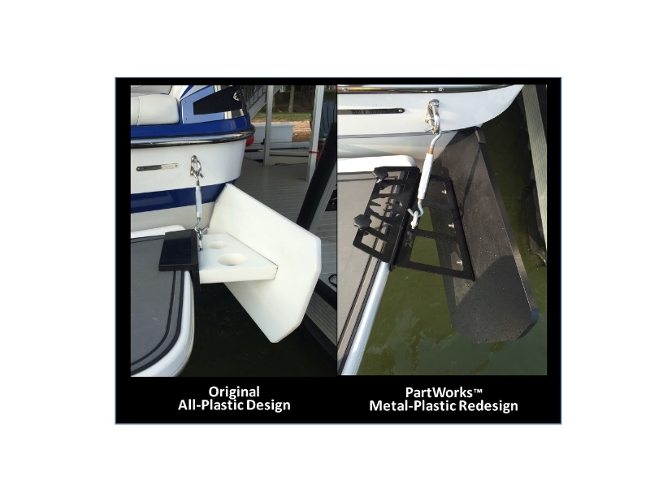

A family-owned business with a passion for wakesurfing, Wicked Wakesurf Designs sells aftermarket boat paddles that create huge, perfectly-formed waves without the expense of buying a new boat. By working with PartWorks, Wicked Wakesurf dramatically redesigned and improved their product, converting an all-HDPE plastic product to a smart combination of metal and plastic. The redesigned product is easier to install, more durable and more stylish. Wicked Wakesurf also outsourced the manufacturing, packing and shipping of their products to PartWorks so they could focus on marketing and sales without worrying about meeting product demand.

“PartWorks’ invaluable design and production expertise has resulted in product improvements and scalability of operations that will drive the growth of our business beyond our wildest dreams,” said Joe Herzberger, founder of Wicked Wakesurf Designs.

Using 3D modeling, 3D CAD Design using Solidworks and Prototyping, PartWorks redesigned and prototyped the Wicked Wakesurf aftermarket boat wake surfing paddle from all-plastic to plastic and metal, making it easier to install, more durable and better looking.

Wicked Wakesurf was facing production challenges, as each boat make, model and year can have a different transom profile the paddle must hug. By leveraging Partworks’ 3D laser scanning capabilities featuring Faro scanners to replace the process of manually cutting templates, Wicked Wakesurf can create custom fitting paddles more quickly, expanding their target market. Their new website will be live by the end of July.

PartWorks are taking care of the delivery side of things for Wicked Wakesurf as well, including the packing and shipping of the product — with all hardware and installation instructions — in low volume on a flexible per-box basis. PartWorks even updates consignment inventory and shipping status for billing and tracking purposes. This is excellent news for the small business, as they can focus on other things.

“We enjoy teaming with passionate inventors with great ideas and products like Wicked Wakesurf to take manufacturing off their shoulders so they can focus on growing their business,” said Scott Geller, CEO of PartWorks.