A 3D printed graphene aerogel has been recognized by Guinness World Records as the “least dense 3D printed structure.” Developed at Kansas State University, the material is superelastic, conductive, and incredibly light, meaning it can be applied to improve the abilities of electronic objects and batteries.

Better batteries, smart wearables and flexible LED screens

Characterized with mechanical strength exceeding steel, electric and thermal conductivity, and unusual magnetic properties, the global market for graphene has boomed since its rediscovery by Andre Geim and Konstantin Novoselov in 2010.

Rise in interest matches a global demand for better power sources for electronic devices, and future technologies like smart wearables and flexible LED screens. The challenge with graphene is still to produce at scale and retain the properties that make the material so intriguing.

With the flexibility afforded it as a fabrication method, 3D printing has been used in a number of ways to unlock the material’s potential.

Research led by the James M. Tour Group at Rice University, Texas, uses a method of laser 3D printing to extract the material from sugar crystals and create a graphene foam.

At MIT, researchers have taken a mathematical approach to graphene’s structure, and proposed a gyroid as the optimum 3D shape. Graphene oxide has also been used at the Harbin Institute of Technology to create structures matching the performance of high-strength concrete.

The lightweight, record-breaking graphene aerogel has been developed in a collaboration between assistant professors Dong Lin, Chi Zhou and Qiangqiang Zhang, of Kansas State University, University at Buffalo and Qiangqiang Zhang Lanzhou University respectively. The method they have used takes inkjet 3D printing into deep freeze.

The record breaking 3D printing method

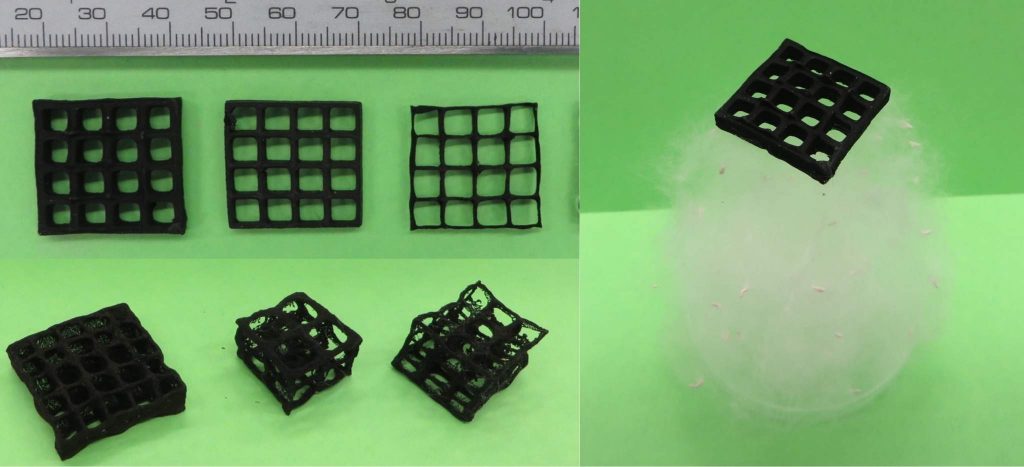

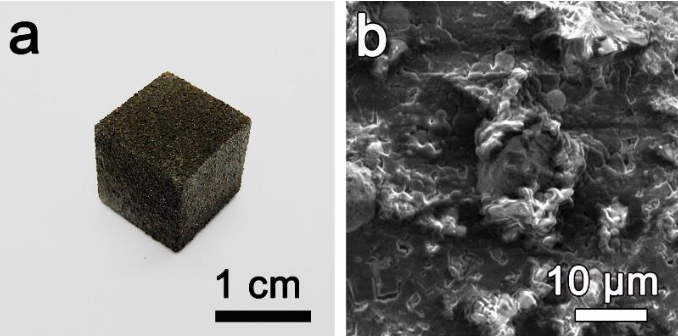

Lin, Zhou and Zhang’s 3D graphene aerogel weighs just 0.5 milligrams per cubic centimetre. As demonstrated in supporting media, this means that fragile objects like flower petals or cotton balls can support a 3D printed quantity of the material without bending.

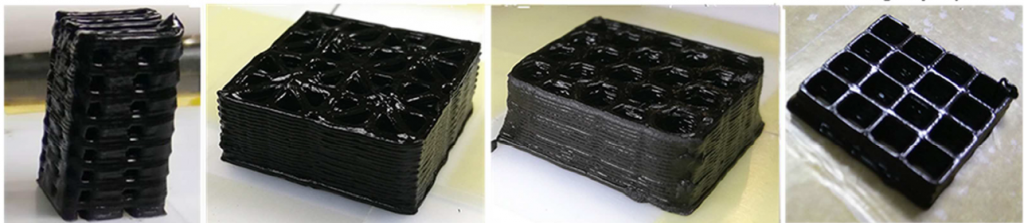

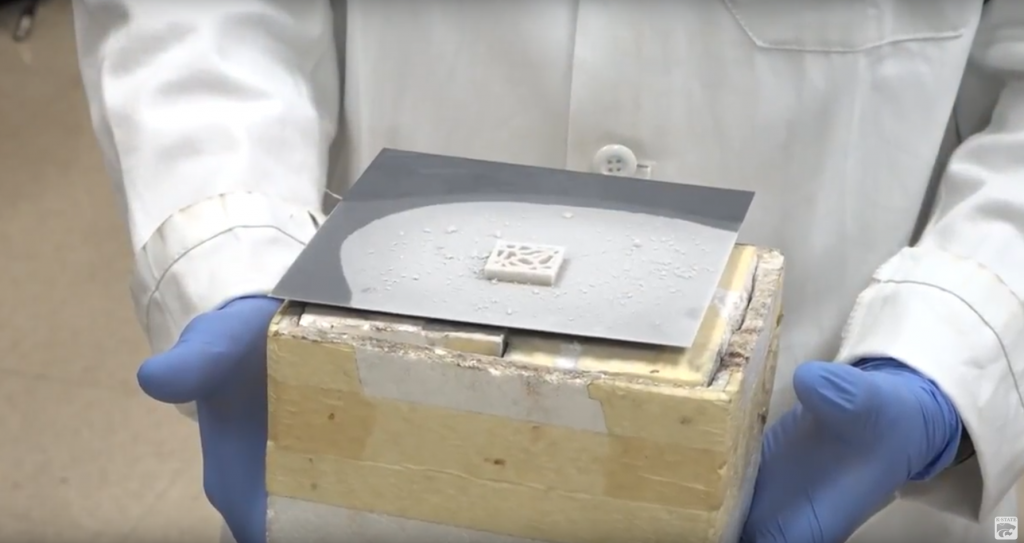

3D structures of the graphene aerogel are made using a specially developed inkjet method of 3D printing. The ink is prepared by mixing graphene oxide (GO) powders with deoinozed (DI) water. This is loaded into two syringe barrels that jet the ink one droplet at a time.

The bed and chamber the ink prints onto has been tuned by the researchers to a cryogenic environment. When the ink is deposited DI water freezes, solidifying the graphene into a 3D shape.

Time-lapse print of the first layer of the Kansas State Wildcats logo. Clip via K-State on YouTube

After printing, the structure undergoes a further two freezing processes to cement the particles together. The final 3D aerogel is uncovered after a 48 hour drying process and thermal annealing.

3D graphene aerogel will make it into the 2018 edition of the Guinness Book of World Records. Supporting research from Lin, Zhou, Zhang and other collaborators Feng Zhang, Sai Pradeep Medarametla and Hui Li can be found in the Small journal, published online February 2016 in Volume 12, Issue 13.

Stay up-to-date with the latest 3D printing news and research by subscribing to our newsletter and following us on twitter and Facebook.

Featured image: The record-breaking 3D printed graphene aerogel defies an ear of wheat in a demonstration of its lightweight density. Photo by Kansas State University