Insiders and analysts have made their predictions on the 3D printing trends to watch out for. Find out more in our series focused on the future of 3D printing.

Biotechnology start-up Nuclera has raised $42.5 million towards the launch of a new desktop 3D bioprinter with the potential to significantly broaden the accessibility of the protein models required for drug discovery.

Known as the ‘eProtein,’ this system is designed to ramp up the rate at which scientists can create the samples needed to study protein-to-protein interactions (PPIs), tests that are vital to better understanding and treating deadly diseases.

By reducing the lead times of such models from weeks or months to just 24 hours, the machine’s creators say that it could not only help accelerate drug discovery, but make it easier and more ergonomic to achieve. To help make this ambition a reality, Nuclera’s newfound funding is therefore set to be used for both accelerating its bioprinting R&D, and bringing the technology to market for the first time.

“The key to making drug discovery accessible is making proteins accessible,” Michael Chen, Co-founder of Nuclera told Sifted. “So we want our customers to be able to have these bioprinters right at the benchtop, to be able to make proteins and ultimately characterize proteins and discover drugs against these proteins on a single platform.”

“The new financing and partners we are announcing today is a strong vote of confidence in our mission to increase the accessibility of drug discovery.”

Nuclera’s ‘digital microfluidic’ technology

Established back in 2013, by three scientists studying for their PhDs at the University of Cambridge together, Nuclera is a biotech firm on a mission to improve access to scientific experimentation. This ethos was developed by the company’s Co-founders personally, who say that “inaccessibility was the key bottleneck in biology” during their studies, thus they began dreaming up new ways to address this.

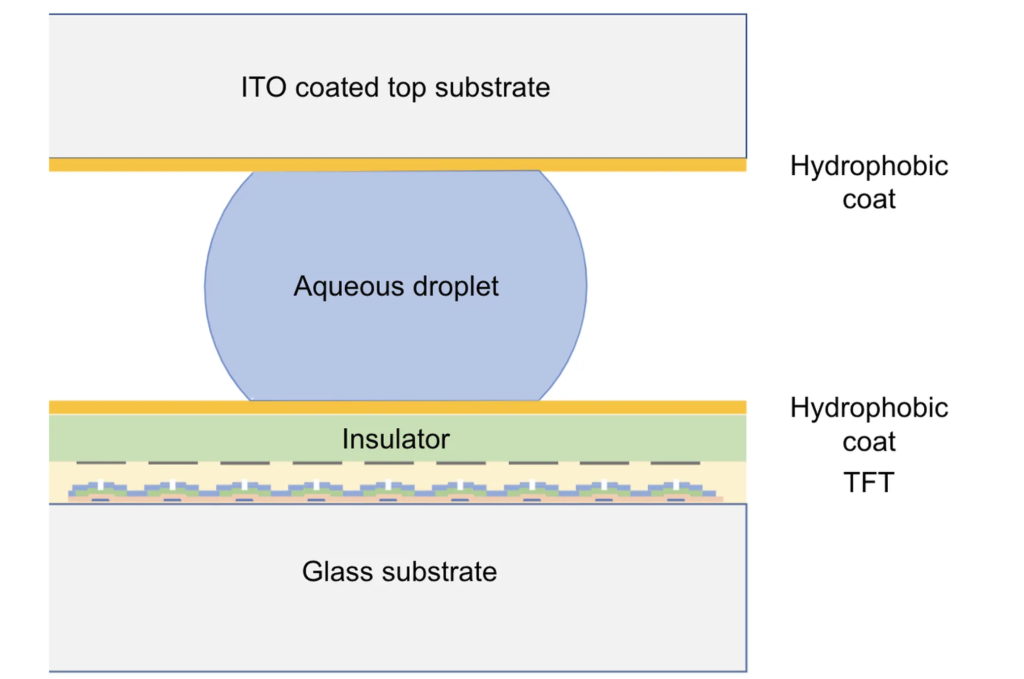

What the scientists came up with was an approach that they call ‘eDrop digital microfluidic’ technology. In essence, this lab-on-a-chip approach harnesses the TFT electronics used to create consumer displays, to screen applied DNA droplets for protein expression, before turning these signals into purified nanoliter-scale 3D printed proteins.

In doing so, the technology effectively democratizes the process of analyzing mammalian, insect, plant and bacterial cells, which currently requires a significant amount of financing and lab equipment to achieve. According to Chen, Nuclera’s eDrop approach therefore has the potential to address biotech’s “fundamental productivity problems of today,” as well as the clinical challenges of tomorrow.

“Immunotherapy is a type of treatment that is used to treat cancers and other human diseases,” explains Chen. “Immunotherapy is just a protein that they’re getting injected into their body. What if we could use this to manufacture drugs for people in a distributed fashion, not necessarily in a central manufacturing plant, but throughout hospitals, clinics and even in the home environment?”

Marketing protein 3D bioprinting

Backed by investors old and new, including M&G, Amadeus Capital Partners, E Ink, RT Partners, Future Planet Capital, G. K. Goh and the British Business Bank Future Fund, Nuclera’s Series B funding round has provided it with the funding needed to seriously ramp up the development and application of its eProtein bioprinter.

At first, the firm intends to target research and drug discovery clients with its new machine, as it anticipates being able to address their protein production and screening needs, before going on to integrate its technology into a more ambitious system with wider capabilities.

In fact, using its recently-raised capital, Nuclera has outlined plans to build an “all encompassing proteomics platform.” Although the company has yet to reveal the exact form this machine will take, it says the system will “unify protein expression and characterization,’ in a way that “increases scientific reproducibility, accelerates drug discovery and contributes to the ever-expanding bio-economy.”

“Nuclera is bringing rapid prototyping—a concept that did not exist until now—to biotech, and by speeding up research and opening up completely new avenues of innovation, it will have a far-reaching impact in numerous markets,” adds Andrea Traversone, Managing Partner at Amadeus Capital Partners. “Nuclera’s eProtein platform unites the very fragmented workflow that currently exists in proteomics.”

“We have been very impressed with the quality of the team that Michael and his co-founders have assembled and the unique technology they are developing.”

3D bioprinting’s investment boom

Despite the fact that 3D bioprinting remains at a relatively early stage of development, and many such technologies haven’t yet been brought to market, a huge amount of capital has been poured into their development over the last year.

Towards the end of 2021, 3D Systems doubled down on its commitment to developing 3D bioprinted organs, with its acquisition of Volumetric Biotechnologies. Set to be worth up to $400 million, the deal could allow the firm to broaden the application of its ‘Print to Perfusion’ process, and move from focusing lung scaffolds, to bioprinting two further organs.

Shortly afterwards, Inventia Life Science raised $25 million of its own to help accelerate the commercialization of its proprietary RASTRUM 3D bioprinter. At the time, Inventia said that its cell-culturing technology had the potential to carve out a niche in a biomedical research and drug discovery market, which it estimated to be worth over $40 billion.

Elsewhere, regenerative medicine start-up Healshape has also raised a significant amount of capital to fund the R&D of its 3D bioprinted breast implants. Based around living patient cells, the company’s tissue grafts are designed to help treat women who have undergone a mastectomy after breast cancer, and are said to feature a much-reduced risk of rejection.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

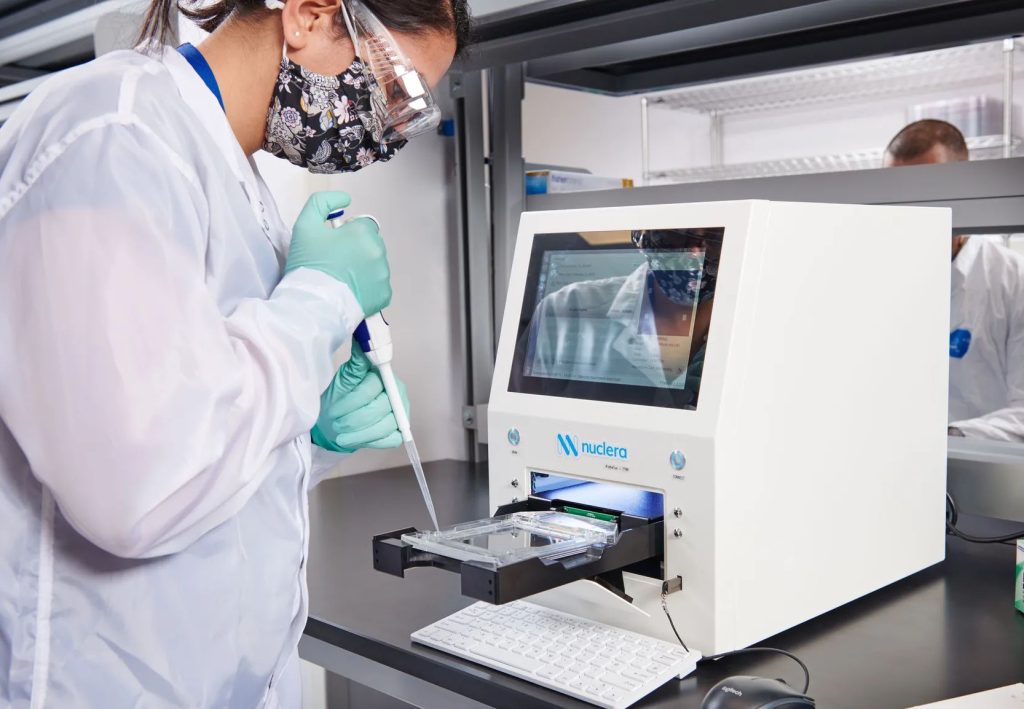

Featured image shows an engineer using a Nuclera system. Photo via Nuclera.