Insiders and analysts have made their predictions on the 3D printing trends to watch out for. Find out more in our series focused on the future of 3D printing.

German 3D printing technology developer Headmade Materials has secured EU funding worth up to €5.8 million.

Having fought off competition from over 1,000 other firms, as part of the European Innovation Council (EIC) Accelerator Program, an initiative set up to help innovators scale the development of emerging technologies, Headmade now aims to use its newfound capital to accelerate its expansion, and ramp up its material production.

“We are very proud to have been selected for the EIC Accelerator program and to have prevailed over 1,000 other companies,” said Christian Staudigel, CEO of Headmade Materials. “This not only underlines the relevance of 3D printing for industries in Europe, but also that we are on the right track with our Cold Metal Fusion (CMF) technology.”

“We see this nomination as an obligation to make our technology available, also internationally, to as many users as possible and as quickly as possible.”

Cold Metal Fusion technology

While Headmade wasn’t spun-off from research institute Das Kunststoff-Zentrum (SKZ) until 2019, Staudigel has been developing its proprietary CMF process alongside fellow Co-founder Christian Fischer for around seven years now.

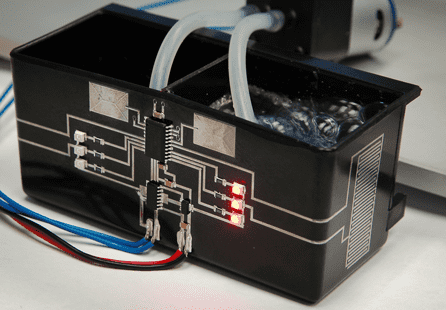

Essentially a mixture of metal sintering and SLS, what sets the firm’s manufacturing method apart from regular SLS processes, is its in-house developed 3D printing materials. These alloys are said to feature an integrated plastic binder matrix, designed to improve their flowability, as well as make them compatible with a wide range of machines.

In practice, the CMF process has four steps, starting with a part being printed in an SLS-like fashion, but at a lower temperature of 80°C, in a way that reduces the time required to heat and cool it. Resulting ‘green’ prints are then post-processed, debinded in a solvent and sintered into fully-dense metal components, as part of a workflow that Headmade says is “easy to integrate” into third-party machines.

One area that the technology has particularly excelled in thus far, is the production of bike parts, with service bureau Element22 working with Headmade to 3D print novel clipless titanium pedals in March 2021. Initially only made available for backing on Kickstarter, these ‘My Ti’ parts were later launched by the companies under the joint Titanum brand.

Following the success of their initial partnership, the firms then teamed up again to develop weight-optimized parts for Sturdy Cycles’ Fiadh titanium road bike. During the project, the duo found they were able to print functional crank arms, frameset connectors and chainstay elements. This led Sturdy Cycles to shift many of its parts’ production to CMF, a move that showcased the tech’s series production potential.

Headmade’s EIC program success

Established to help support SMEs, particularly those recently-founded or spun-out from other firms, the EIC’s Accelerator Program offers financial backing to those developing what it calls “game-changing innovations.” Alongside direct equity investments of as much as €15 million, the initiative also provides non-dilutive grant funding worth up to €2.5 million, and other coaching services to EU businesses.

The project is the brainchild of the EIC, which itself was founded under the Horizon Europe program, a six-year scheme designed to promote EU innovation and entrepreneurship between last year and 2027. Armed with a €10.1 billion budget, the EIC has been tasked with backing those firms developing early-stage or proof-of-concept technologies, and one way it does so is via its Accelerator Program.

To decide which companies get to benefit from the initiative, which last year had a whopping budget of €627 million, the EIC invited eligible firms to apply for funding in June 2021. As it turned out, 1,109 businesses from 21 different countries applied for support, with just 99 of these eventually being selected due to their ‘strategic relevance,’ and potential to ‘define industries with their innovative power.’

As one of those companies chosen, Headmade has now been awarded funding worth up to €5.8 million, the single largest investment it has received to date. Thanks to this fresh cash injection, the firm says that moving forwards, it could be able to scale its feedstock production, expand its portfolio to include further materials and broaden its international sales efforts.

“Speed is one of the keys to success, especially in the competitive international environment,” adds Marius Geldner, CFO of Headmade Materials. “The funds from the EIC Accelerator program will give us the additional resources we need to increase our speed even more and offer our technology to a broader international customer base.”

EU-backed 3D printing innovation

Much in the same way that America Makes operates in the US, and Innovate UK works in Britain, the EU’s innovation programs are constantly seeking to fund new technologies that really push the envelope of what’s possible with 3D printing.

In June 2021, for instance, the EU’s Future and Emerging Technologies program awarded funding to Microlight3D, to help further the R&D of a novel 3D printable concrete it’s been developing. Said to feature unique temperature-regulating properties, it’s thought that in future, the material could enable the construction of ‘self-cooling’ buildings.

German electronics 3D printing firm Neotech AMT also launched its EU-backed AMPERE Project last year. Set up with the aim of developing reliable and scalable hybrid additive manufacturing processes for creating multi-functional mechatronic systems, the collaborative research program is set to continue until 2024.

However, when it comes to creating a legal framework in which 3D printing can thrive, a power that the EU has over conventional national accelerators, it has often been accused of coming up short. While the likes of CECIMO continue to lobby the EU’s bodies and report on the technology’s progress in Europe, researchers have also said that its medical device regulation is lagging behind that of the US.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Headmade logo 3D printed onto a part using CMF technology. Photo via Headmade Materials.