3D printer and microdispensing system manufacturer nScrypt, headquartered in Orlando, Florida, has been awarded a patent for a new high-speed micro additive manufacturing method. The patent addresses applications that call for a wider material palette or technology capable of 3D printing onto a range of shaped surfaces.

“There is a real need for a high-speed 3D printing method that can produce patterns on flat or conformal surfaces and to build 3D structures with multiple materials in multiple layers, some of which may be conductive,” comments Dr. Ken Church, CEO of nScrypt.

“This patent reflects our pioneering work to solve this problem with micro-dispensing.”

What is microdispensing?

Microdispensing is a method of depositing droplets of ink in volumes of less than one microliter. Without necessarily relying on heat to melt the inks, or the low viscosity inks needed for ink jet printing, microdispensing is incredibly diverse in terms of its material choice. In contrast to methods like SLA that would require multiple vats to switch materials, microdispensing also facilitates multimaterial 3D printing.

Such versatility has earned microdispensing a place across a wide variety of industries. For example fabrication of smart devices, electronics, conformal antennas and microfluidic devices.

Patented multimaterial 3D printing

nScrypt’s trademark microdispensing technology relies on the SmartPump syringe-based dispenser, which is at the heart of the company’s most recent patent. At present, the SmartPump is compatible with over 10,000 commercially available materials of varying viscosity, from liquid inks, through to pastes, epoxies and conductive materials.

Specifically nScrypt’s Patent No. 10,059,056 B2, “Micro-dispensing Multi-Layered 3D Objects with Curing Steps,” relates to a SmartPump-powered system that can use materials “loaded with nano to micron sized particles, tubes, or strings.”

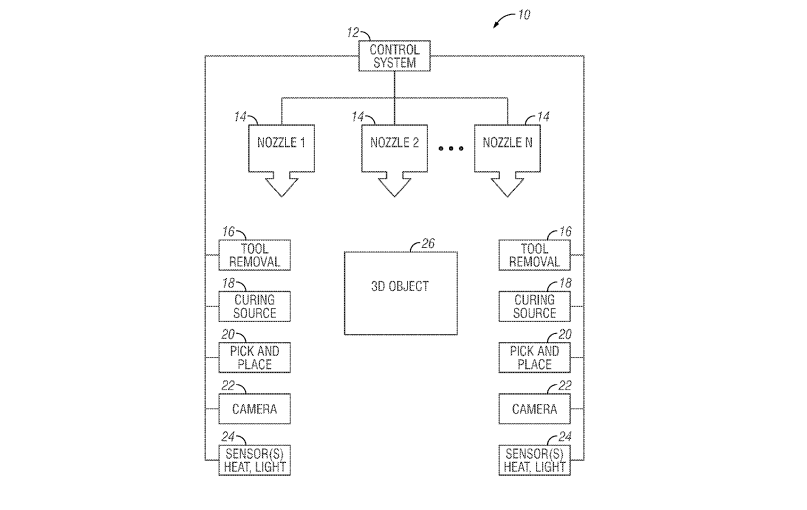

Three independent claims are made by the patent. First of all, between each microdispensed layer, material is cured by lasers or UV light sources. Secondly, a system that uses multiple nozzles to make multimaterial structures. And thirdly, the potential of curing multiple layers using either a photo, thermal, electrical, inductive, or chemical source. A further sixteen dependent, more specific, claims are also made, relating to pick and place capability, and real time process monitoring.

Other activities at nScrypt

Scheduled for launch in February 2019, nScrypt is also the developer of the NASA-sponsored 3D BioFabrication Facility (BFF) which will be installed aboard the International Space Station (ISS).

In other recent news, nScrypt launched nScrypt Cyberfacturing, an in-house additive manufacturing bureau.

For more 3D printing news subscribe to the 3D Printing Industry newsletter, and join us on Facebook and Twitter. Start a new career or find additive manufacturing experts, visit 3D Printing Jobs now.

Featured image shows sample objects inside an nScrypt 3Dn system. Photo via ahanktcd on YouTube