Arizona-based engineering and 3D printing service provider, Phoenix Analysis and Design Technologies (PADT), has announced a U.S patent for its Support Cleaning Apparatus (SCA) system.

Rey Chu, the co-founder of PADT, said, “we used computational fluid dynamics simulation, our extensive product development skills, and knowledge from over two decades of 3D Printing experience to design the industry’s most efficient and reliable support cleaning solution. We are proud that our SCA system has now been granted patent protection.”

Removing FDM support material

Parts with structural overhangs exceeding 45 degrees are 3D printed with support material. These supports must be removed during post-processing. However, the removal of the support structure requires additional labor and may also damage the 3D printed component.

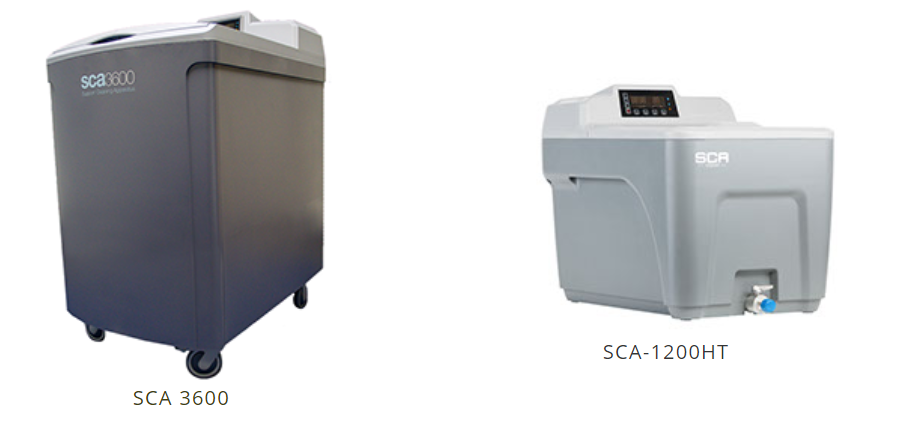

Officially known as “Method and Apparatus for Removing Support Material”, the cleaning system is “currently sold exclusively by Stratasys”. The SCA is suitable for use with Stratasys 3D printers that use Soluble Support Technology (SST) materials such as, ABS, polycarbonate, nylon and PolyJet resins. The system is intended to reduce post-processing time and labor costs.

The SCA is essentially a bath of PADT’s proprietary cleaning liquid. To remove the support material, the 3D printed model is submerged into the pool of chemicals, which dissolves the support structure. The process does not affect the mechanical properties or the chemistry of the original model.

For optimum results, material-specific temperature settings can also be chosen.

3D printing post-processing

As additive manufacturing technology is increasingly adopted by industry, there is an increasing focus on efficient post-processing of 3D printed components.

Zortrax, a Polish 3D printer and filament maker, released its Dissolvable Support System for automated removal of support material. Earlier this year, the company also released water-soluble composite, Z-SUPPORT, to print support material which dissolves easily.

One alternative to support removal is offered by Rize Inc. The Rize Augmented Polymer Deposition method combines FFF/FDM with an inkjet system to 3D print parts with supports that snap-off without the next for a chemical bath.

In metal additive manufacturing support removal is also a necessary stage. Last year, Materialise, a Belgian AM company, introduced its proprietary software e-Stage for metal 3D printing. The software uses an algorithm to generate a support structure for metallic parts which minimizes contact of the support with the model. The support structure can then be removed relatively easily. Materialise e-Stage for metal was nominated by our readers for a 2018 3D Printing Industry Awards.

These developments in research show the manufacturing industry’s goal to minimize or eliminate the need for post-processing 3D printed parts.

Stay in touch with the latest news developing in the 3D printing industry by subscribing to our 3D printing newsletter. Join us social media: Facebook and Twitter.

For jobs in the industry, please visit our 3D printing job site.

Featured image shows PADT’s SCA-1200HT . Image via PADT