3D Printing Industry first previewed the Inventure 3D printer at the Zortrax Experience Conference in June. At launch, the Inventure was capable of working with Z-PLA, Z-PETG, and Z-SUPPORT materials. The company has since expanded this range with 3 advanced filaments, boosting resilience, flexibility and post-processing convenience.

Plus resilience

An ABS-based material, Z-ULTRAT Plus is Zortax’s solution for durable, strong and functional prototypes. The company’s tagline for the product is “The Real

Resilience” highlighting its high impact resistance, and ability to withstand temperatures over 90 °C.

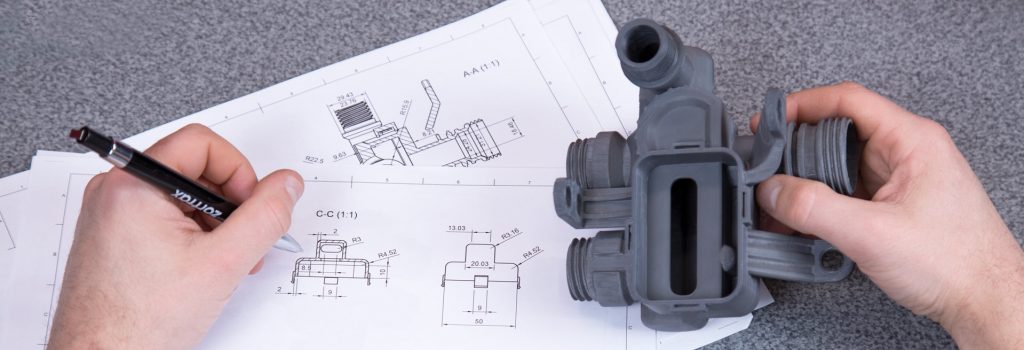

In example use case for the material, Zortrax 3D printed a heater control valve, as used to regulate temperature in car engines. With the prototype, development engineers can conduct preliminary operation tests of the valve’s design, and pinpoint any areas for improvement.

Z-ULTRAT Plus is available in 6 different colors – blue, red, orange, graphite,

ivory and pure black. Combined, the colors can add clarity to a manufacturing prototype, enabling designers to pinpoint the exact parts for modification.

Plus post-processing

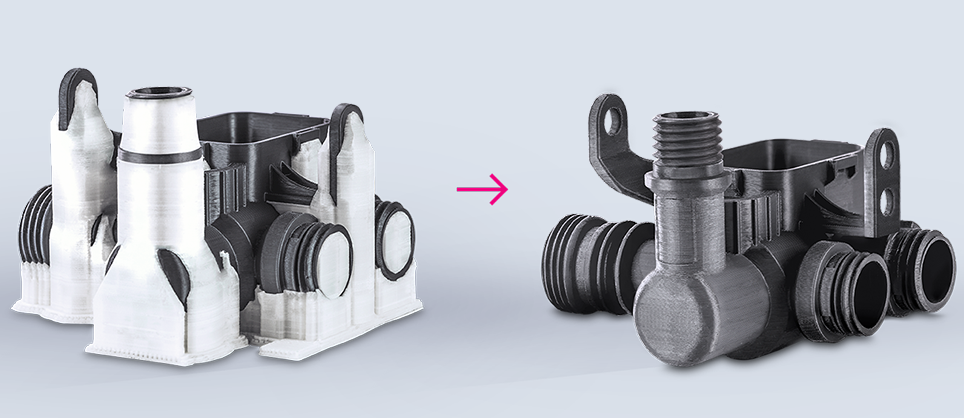

Z-ULTRAT Plus is also compatible with Zortrax’s latest Z-Support Plus material. An upgraded of the standard Z-SUPPORT material (which is compatible with Z-PETG, Z-PLA and Z-SEMIFLEX) Z-SUPPORT Plus is engineered for the build chamber environment required to 3D print ABS-like filaments.

Both materials in the Z-SUPPORT range are soluble in water, making post-processing a breeze. For a fully “hands-free” experience, the user can simply put a part 3D printed with Z-SUPPORT into the Zortax Dissolvable Support System (DSS System). After soaking for some time, a completely residue-free part is removed “like magic”.

The solubility of this material makes it invaluable to complex 3D printed objects with moving parts.

Plus flexibility

Z-SEMIFLEX is plastic and rubber combined. Based on TPU, Z-SEMIFLEX is a hard, yet flexible material “resistant to tearing, abrasion, impact and temperature over 130 °C.”

Items made from the material can be stretched, but retain their shape when resting. In a use case for the material, Zortrax 3D printed a universal joint rubber boot, used to cover parts of machinery that would otherwise collect and debris – like those found on a car’s gearstick or serving as suspension springs in bikes. Typically, when covering a lever, rubber boots have to be lubricated. Z-SEMIFLEX handles grease and chemical resistance well.

Custom-made end use objects can be made in Z-SEMIFLEX, and the 3D printer filament is potentially suitable for spare-parts programs, or any prototypes subjected to intensive testing.

Availability

Zortrax’s new range of Plus materials are available from the Zortrax online store. For notifications about additions to the range, visitors can also sign-up for updates directly from the provider.

Stay ahead of 3D printer materials, hardware and software updates by subscribing to our free 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

We want to know about the best 3D printing filaments and materials. Make your nominations for the 2018 3D Printing Industry Awards now.

Featured image shows a motor prototype 3D printed with Z-SUPPORT Plus and Z-ULTRAT. Image via Zortax