Amongst the 250+ exhibitors at this year’s TCT Show in Birmingham, I was given the opportunity to speak to Rize Inc. founder and CTO Eugene Giller. A previous employee of ZCorp – the full color, binder jetting 3D printing pioneer that is now 3D Systems – Giller officially founded Rize in 2014, after spending four years collecting the technology that would become the Rize One.

Material jetting plus FFF

With extensive knowledge and experience of the binder jetting process, Giller noticed an area for improvement in powder handling, he says “I was sick of coming home covered in powder.” In addition, he believed that post processing could be made a lot easier. By combining material jetting with common FFF, Giller and his team of engineers developed the Augmented Polymer Deposition (APD) process.

The technology behind “zero post processing”

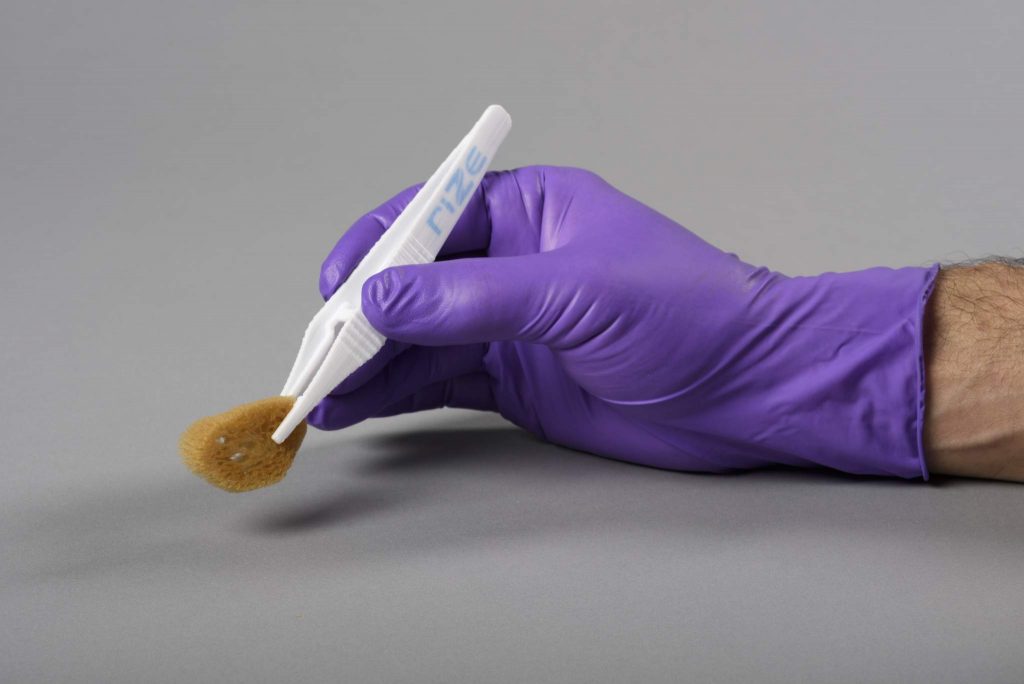

Material jetting is the step that enables Rize One’s “zero post processing” motto where supports on 3D printed parts can simply be snapped off by hand. The technology also allows color gradients, with space for full color spectrum developments in the extra MYK units beside the print head.

Asking Giller about the future of the technology, he explained “Customer demand is different from what I’d like. At the moment we are getting requests for color, but what I’d really like to see is medical applications,” e.g. tools and devices.

Giller added that there are additional plans to expand Rize One’s feedstock selection, including further experimentation with multiple materials.

Material development

The proprietary material developed by Rize is a closely guarded secret, used by no other company in the industry. Like most polymers however, it is based on natural gas, and can withstand medical grade sterilization.

Giller explains “it [the material] is biocompatible, but it is not biodegradable. We don’t want it to be biodegradable however, as we want our products to last.”

Having launched only three years ago, Rize materials do not have medical certification yet as the process typically takes upwards of 7 years. In this time though, the company remain committed to those developments that best suit customer demand.

Commercial shipments of the Rize One started June 2017.

Exclusive 3D printing interviews can be found on our Facebook, Twitter and in our regular newsletter.

Seek your next opportunity in additive and register on our 3D printing jobs site here.

Featured image shows Eugene Giller and the Rize One 3D printer at TCT 2017. Photo by Beau Jackson for 3D Printing Industry.