This edition of our 3D printing news digest Sliced follows the latest developments in strategic collaboration between EOS and Siemens; commercialization of Evolve Additive Solutions’ STEP technology; and the installation of the largest 3D printed coral reef in the Maldives.

Additional news derives from ARRK Europe, the Southwest Research Institute, Mimaki USA, the Standard Bank Group, and more.

Commerce in additive manufacturing

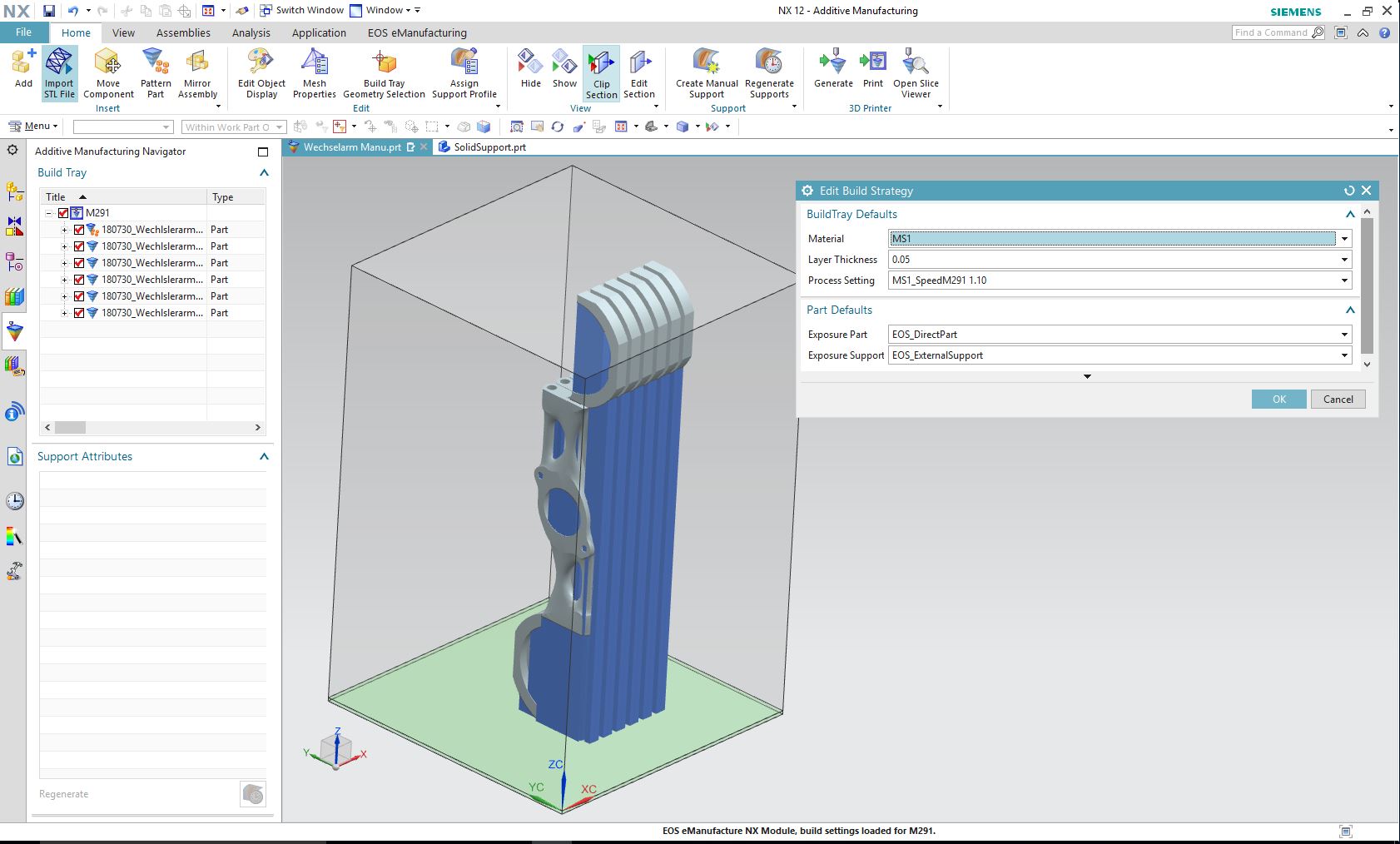

EOS, a German industrial 3D printing solutions provider, has announced further collaboration with Siemens, Europe’s largest industrial manufacturing company. Together, the companies plan to expand additive manufacturing software development, drive components and automation.

EOS’ M 300 series of direct metal laser sintering (DMLS) systems, which debuted this week at IMTS 2018, as well as the EOS P 500 system, showcased first time at last years’ formnext fair, are now equipped with drive components from Siemens’ Totally Integrated Automation (TIA) portfolio.

The EOS P 500 system will also be added to Siemens’ Additive Manufacturing Experience Center (AMEC) in Erlangen, Germany. Furthermore, EOSPRINT 2, an open and productive CAM software, has been integrated in Siemens NX 12 to better connect additive manufacturing processes from design to advanced 3D printing within EOS systems.

Evolve Additive Solutions, a Minnesota-based subsidiary of Stratasys, has announced the shipment of its first alpha stage Selective Toner Electrophotographic Process (STEP) system. STEP is a new 3D printing technology said to be up to “50 times faster than the next fastest AM plastics technology.”

“As the co-inventor of STEP and being the executive in charge of development over the last nine years, it’s not only exciting but critical that we get the technology into a customer’s hands for development of real-world applications,” said Steve Chillscyzn, CEO of Evolve Additive Solutions.

ARRK Europe, product development specialists based in the UK, has launched a new online quoting and ordering service for 3D printed Stereolithography (SLA) and Selective Laser Sintered (SLS) parts. With this service customers can upload their CAD data, specify their SLA or SLS requirements and receive an instant quotation.

Mimaki USA, a manufacturer of wide-format inkjet printers headquartered in Japan, has signed New York-based CAD BLU as a national dealer for its 3DUJ-553 full-color industrial 3D printer.

Florida-based 3D bioprinter developers nScrypt has brought Newton Cyberfacturing, an additive manufacturing service bureau, in-house to form nScrypt Cyberfacturing. Mike Newton, co-founder of Newton Cyberfacturing, and Dr. Ken Church, President and CEO of nScrypt established Newton Cyberfacturing in 2012 while maintaining their separate companies. Now, Newton will now run nScrypt Cyberfacturing and hold his current position as nScrypt’s Director for Electronic Packaging, 3D printed electronics, and functional devices.

“nScrypt’s new business unit will have three strategic focus areas: direct digital design & product co-development with our cyberfacturing customers; digital multi-material manufacturing of the co-developed designs using nScrypt’s digital manufacturing equipment; and modular turnkey cyber-based manufacturing systems,” said Newton.

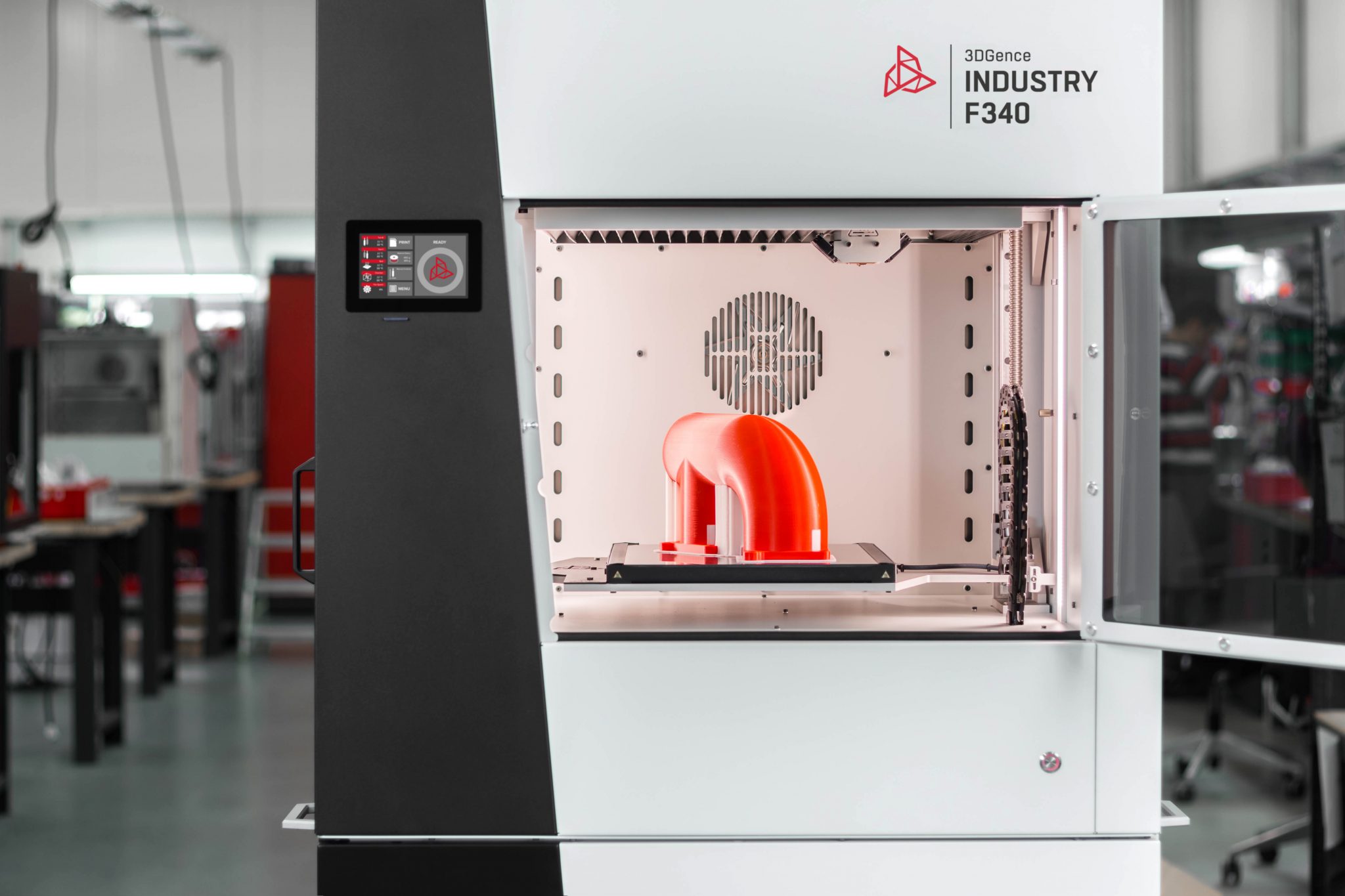

The 3DGence INDUSTRY F340 receives certification

The INDUSTRY F340, a dual nozzle industrial 3D printer from Poland’s 3DGence, has been certified by the global technical service provider TÜV Rheinland to confirm product quality and safety. To test the print quality of the INDUSTRY F340 3DGence, order a free 3D print sample in the form of a helical compound gear, a brake caliper, or an indexing gear.

Educating students and the workforce with 3D printing

The Standard Bank Group, based in Johannesburg, South Africa has commenced a social campaign on Twitter which turns positive tweets into tangible 3D printed educational tools. As part of the Standard Bank Tutuwa-BRIDGE School Programme, South Africans are encouraged to tweet something inspirational with the hashtag #GoodFollowsGood; for every positive tweet, Standard Bank’s Tweet Machine, a mobile industrial container which links social media to 3D printers and laser cutters, will produce up to 1000 set square and ruler kits for grade 6 learners.

Tech Mahindra, a multinational IT provider based in India, has partnered with FutureSkills, an initiative by India’s National Association of Software and Services Companies (NASSCOM), to reskill and upskill Tech Mahindra’s workforce in new technologies. This includes Robotic Process Automation (RPA), Artificial Intelligence (AI), Internet of Things (IoT), Cloud Computing and 3D Printing.

Medical 3D printing advancements

Aether, the San Francisco-based biotechnology company behind the multi-tool Aether 1 3D bioprinter, has announced a collaboration with researchers from the University of California, Los Angeles (UCLA) Henry Samueli School of Engineering to improve the fabrication process for 3D printing artificial muscles with soft materials. The Aether 1 will be optimized through new techniques and algorithms to improve additive manufacturing for such materials.

UCLA researchers will also join Aether’s medical imaging AI collaboration with Harvard Medical School through exclusive access to Aether’s un-released visualization AI software (set to launch in 2019) which includes featuring Automatic Segmentation and Reconstruction (ASAR) technology.

Longeviti Neuro Solutions, a neurotechnology company based in Maryland, has announced the U.S. commercial launch of its novel ClearFit implant solution which corrects bony voids or defects of the cranium. With ClearFit, Neurosurgeons can upload a CT scan to Longeviti’s Secure File Exchange where a customizable CAD model is proposed and finalized. An implant is then made using 3D printing, with additional help from a design team, for optimal personalization for a patient.

World’s largest 3D printed coral reef

REEF DESIGN LAB (RDL) , a not for profit design studio based in Melbourne, Australia, has created what is said to be the world’s largest 3D printed Reef installed in the oceans of Summer Island, Maldives. Using its Modular Artificial Reef Structure (MARS), designers at RDL created several 3D artificial reefs using lattice structures. Each reef unit was 3D printed and molded in ceramic using slip casting, then the hollow forms were filled with marine concrete and steel reinforcement.

The ceramic materials are used to house transplanted corals, which can be continually divided as they grow to colonize natural reefs. This technology can help coral reefs survive in warming climates.

Creating the fastest human-powered bikes with additive manufacturing

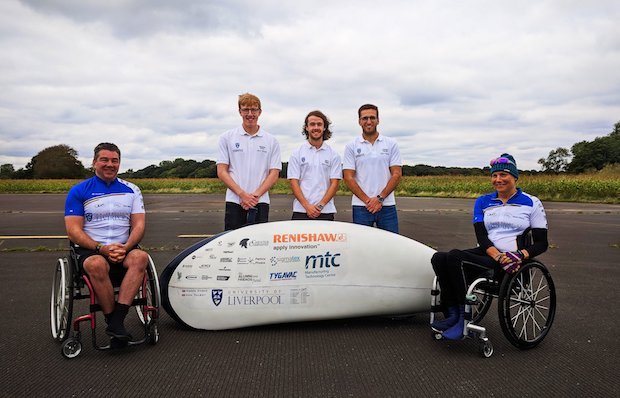

Global engineering firm company, Renishaw is collaborating with the University of Liverpool Velocipede (ULV) Team as part of the ARION project, which aims to build a series of the fastest human-powered bikes in the world.

Using Renishaw’s additive manufacturing machines, the ULV team designed and 3D printed a metal component for the ARION4 bike called the CTS. This part attaches to the headtube to holding the front wheel in place and weighs less than 600g.

“Additive manufacturing provided more design freedom for a vital part of the transmission and steering system. The resulting component is lightweight but offers the strong properties of titanium to help keep control of the bike,” said Llyr Jones, Mechanical Engineer at Renishaw.

The ULV Team are now planning on breaking the hand cycle land speed record, which currently sit at 45.68 mph for a male and 24.85 mph for a female.

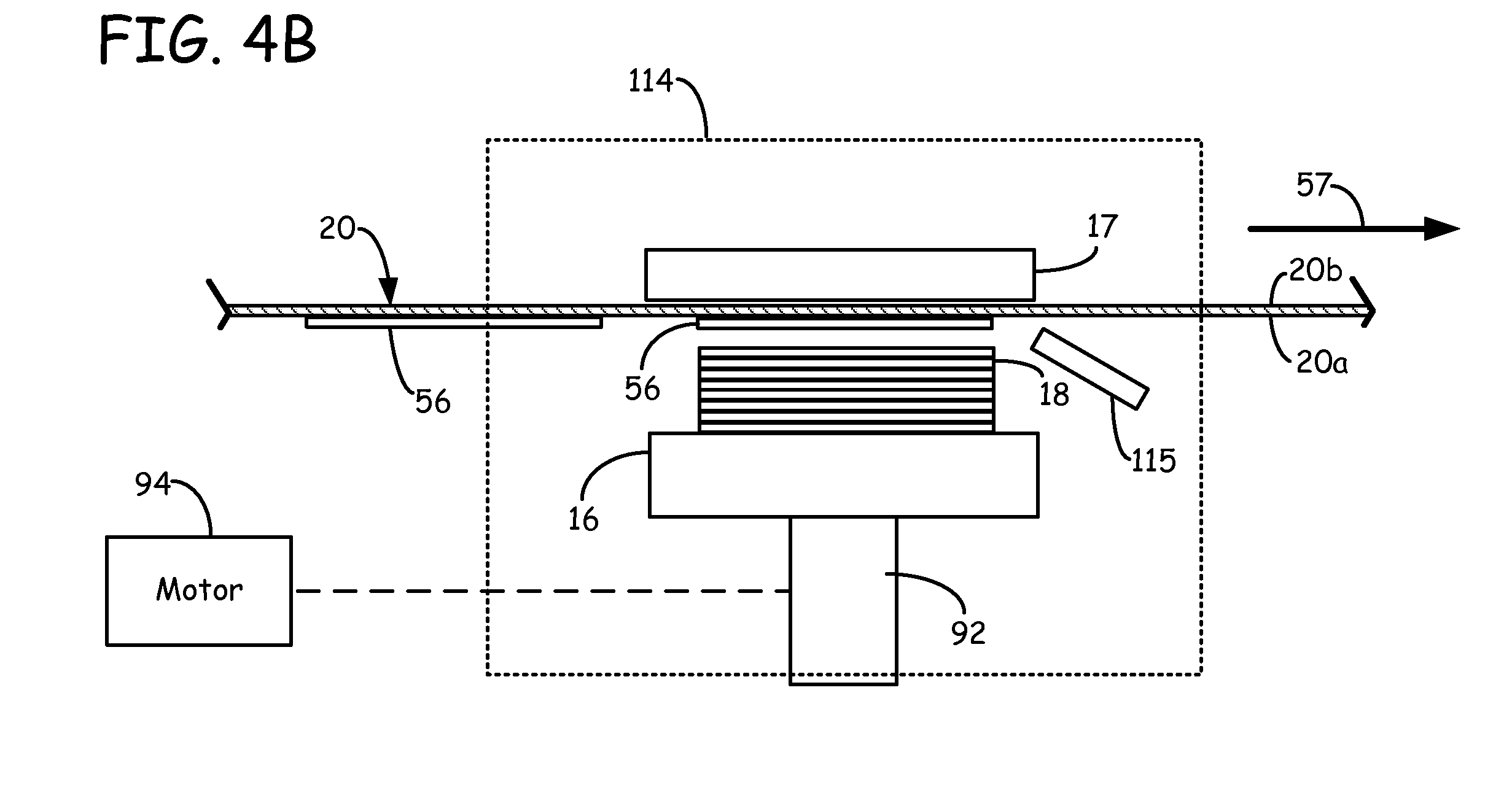

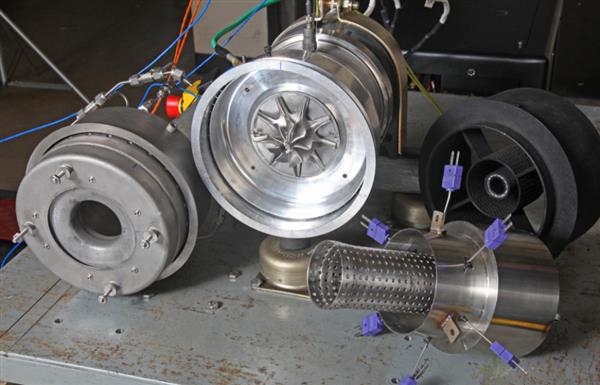

In other news, engineers from the Southwest Research Institute (SwRI) in San Antonio, Texas, are using a customized selective laser melting (SLM) machine to create a cooled, radial gas turbine for a small generator. This generator will provide thousands of hours of electricity to an unmanned aerial vehicle (UAV).

U.S. prosthetic companies, Arm Dynamics, and Ottobock have created a bionic arm and hand prop, complete with 3D printed components, to replicate that of Overwatch character Jesse McCree.

For more of the latest 3D printing news subscribe to our newsletter, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows Sliced logo over the 3D printed coral reef strutures. Photo via RDL/ Alex Goad.