Florida-based 3D printer and microdispensing system manufacturer nScrypt Inc. has announced it is developing a metal 3D printing solution to provide its customers with detailed and repeatable metal parts. Using its microdispensing technology, nScrypt is aiming to specifically provide the metal parts to the aerospace, defense, and medical industries.

3D printing high-strength and high-density titanium parts

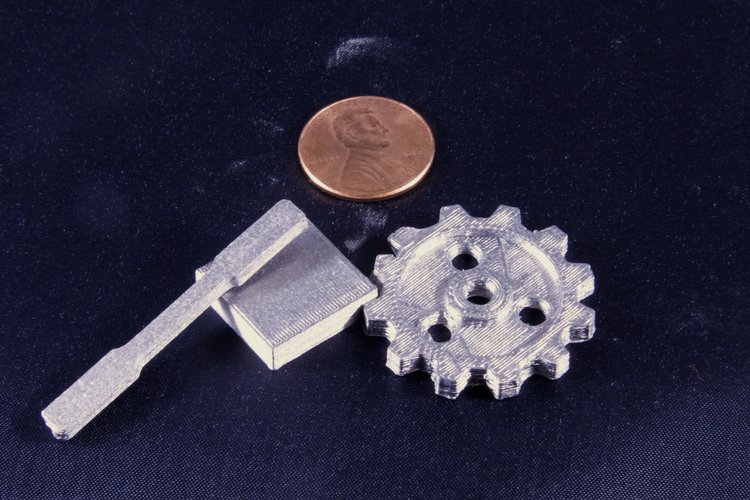

nScrypt has developed a proprietary method for 3D printing parts in titanium (Ti6Al4V), and says the process can be expanded to other metals, including stainless steels, inconel, and copper.

The company has carried out initial tests on its 3D printed titanium, with the parts exhibiting density and strength comparable to wrought metal parts.

The proprietary process involves the use of nScrypt’s microdispensing technology capabilities, which is a method of depositing droplets of ink in volumes of less than one microliter. Microdispensing is a versatile technology, allowing for a diverse material choice without relying on heat to melt the inks, or the low viscosity inks needed for ink jet printing. Its adaptability has lead to its use in a wide variety of applications, and it is now being used by nScrpyt to 3D print titanium parts for different verticals.

Furthermore, nScrypt has also used the ‘nMill’ integrated precision milling head in its Factory in a Tool (FiT) systems to post-process the titanium parts, applying finishing routines with high tolerance features reportedly down to 2 microns (.00008”). FiT systems are capable of 3D printing, milling, polishing, pick and place, and post-processing for complete Printed Circuit Structure (PCS) devices.

Dr. Ken Church, nScrypt’s CEO, explains:

“Our customers want to be able to 3D print metal parts in the same machine that mills them, without tool changes, and to do it without a powder bed, which is our Factory in a Tool. These titanium parts prove that concept.”

Metal additive manufacturing is rocking the 3D printing industry

Metal additive manufacturing has made great strides recently with companies from various sectors opting to 3D print their metal parts, and now nScrypt is helping to push metal AM forward as well. For example, U.S. aeronautics company General Atomics Aeronautical Systems Inc (GA-ASI) is collaborating with award-winning OEM GE Additive to accelerate GA-ASI’s integration of metal additive manufacturing.

Additionally, over in the automotive industry, SLM Solutions, a German provider of metal additive manufacturing systems, is 3D printing metal parts for French high-performance automaker Bugatti.

Meanwhile, Australian metal 3D printer manufacturer Aurora Labs is helping the medical sector to 3D print metal, by developing designs, specifications and parameters for the 3D printing of titanium medical implants.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed titanium gear, dogbone, and block. Image via nScrypt.