In what is thought to be a world first, a set of 3D printed fuel components have been installed in nuclear power plants across Scandinavia.

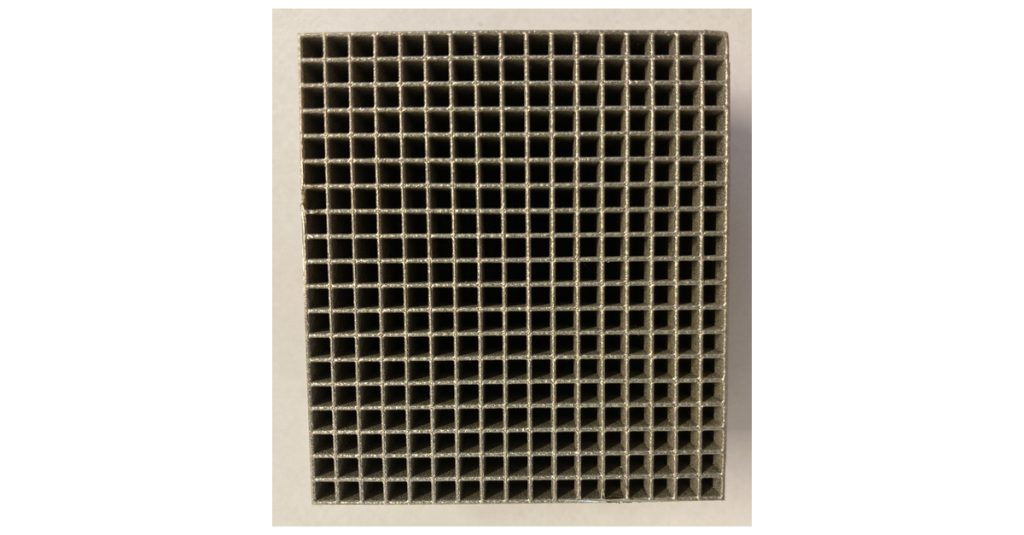

Named StrongHold AM filters, the nuclear fuel debris filters were 3D printed by Westinghouse Electric Sweden, a technology supplier for the energy sector. They’re the first of their kind to be approved for end-use and have been installed at unit 2 of the Olkiluoto nuclear power plant in Finland, as well as unit 3 of the Oskarshamn plant in Sweden.

Although Westinghouse carried out the manufacturing, the metal StrongHold AM filters were actually designed in close collaboration with the operators of the plants, Teollisuuden Voima Oyj (TVO) in Finland and OKG in Sweden.

Carina Önneby, VP EMEA of Fuel Delivery at Westinghouse, said, “As the first 3D-printed fuel debris filter for insertion in a nuclear power plant, the StrongHold AM marks a major milestone in our effort to further improve the boiling water reactor (BWR) fuel reliability by leveraging advances in manufacturing technology.”

What are fuel debris filters?

Nuclear power reactors operate on the principle of nuclear fission, whereby neutrons slam into atoms, splitting them into smaller atoms and releasing energy. This energy is used to heat water and generate steam, which turns a turbine to generate electricity. The fissionable materials are stored in fuel rods and the integrity of these fuel rods is crucial to both the success and safety of the process.

One of the risks in nuclear power plants is fuel failure as a result of foreign debris entering the reactor. As such, fuel debris filters are one of the critical safety measures found in nuclear power generation, as they’re specifically designed to capture debris and stop it from damaging the cladding in a fuel assembly. Without them, power plants would experience more frequent unplanned outages, which is costly.

“Fuel damages can force us to temporarily suspend operations, which affects security of supply and entails unnecessary costs,” explains Andreas Roos, Plant Manager at Oskarshamn 3. “Reducing the risk of fuel damages is very positive for our business.”

3D printing for improved performance

The 3D printed debris filters were actually installed as part of a wider fuel assembly during a recent refuelling outage at the two power plants. According to the project partners, the printed parts contain complex structures that would otherwise have been impossible to manufacture using traditional processes.

As well as being cost-effective to fabricate, the filters also provide improved protection for the fuel assemblies when compared to conventional counterparts.

“We can boast playing a pioneering role, even globally, in the utilization of this new technology at nuclear power plants,” said Arttu Knuutila, Fuel Procurement Team Leader at TVO. “We can now gain important practical experience in the use of 3D-printed metal products which will become an ever more important operational solution going forward. It is important to have a strong network of partners like Westinghouse who deploy additive manufacturing to drive enhanced capability.”

Additive manufacturing is a budding venture in the nuclear sector. Earlier this year, the Ultra Safe Nuclear Corporation (USNC) licensed a novel method to 3D print components for nuclear reactors using refractory materials such as silicon carbide. Developed by Oak Ridge National Laboratory, the approach leverages binder jetting to enable the creation of reactor components more efficiently.

USNC then bought two new 3D printers from Desktop Metal’s recently updated line of X-Series binder jet systems to facilitate their ongoing project. The machines will be used to 3D print innovative fuel designs for use in a new generation of advanced nuclear reactors.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

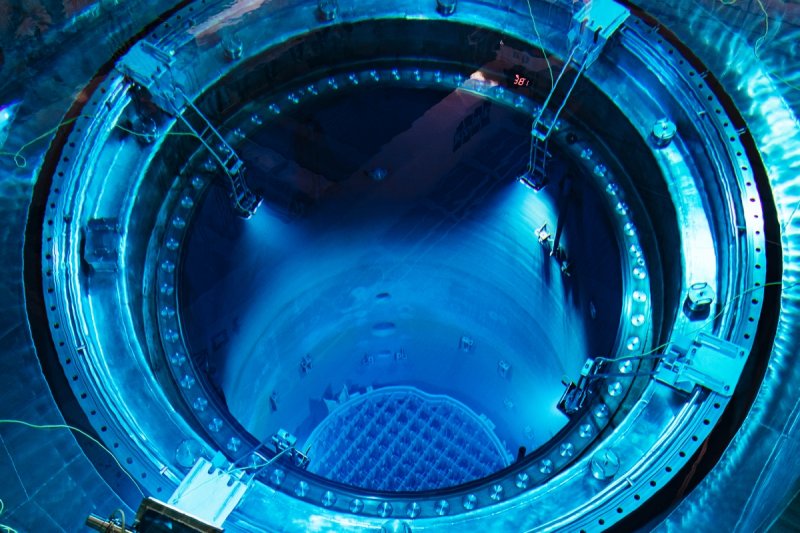

Featured image shows a filter inside the Olkiluoto 2 reactor vessel. Photo via TVO.