Professional 3D printed sports gear manufacturer Athletics 3D has enabled a French biathlete to continue training despite a wrist injury thanks to a 3D printed biathlon rifle hand stop.

In the lead-up to the recent 2022 Beijing Winter Olympics, the athlete had a cycling accident and fractured two bones in his forearm, prompting the French national team to modify the rifle so that he could continue training during his recovery. Leveraging a Zortrax M300 Dual 3D printer and BASF’s Ultrafuse PP GF30 filament, Athletics 3D manufactured a modified version of the rifle capable of withstanding sub-zero temperatures that allowed the athlete to aim and shoot sufficiently.

“In most cases, professional athletes come to us because they need sports equipment that is made and tailored specifically for them to further improve their performance,” said Clement Jacquelin, CEO and Founder of Athletics 3D. “3D printed sports equipment can be customized to accommodate limited movements an athlete has to deal with during the recovery period after an injury.

“In this case, our client has trouble with forearm supination and his ulnar deviation angle was severely limited.”

Modifying the rifle via AM

The aim of the project was to enable the injured biathlete to shoot with a limited ulnar deviation angle, and this meant modifying the hand stop, the part to which the sling is attached to the bottom of the rifle’s stock.

Using a Zeiss scanner, the Athletics 3D team created a precise digital model of the original hand stop, and then began to adapt the part to make it suitable.

“The first thing we changed was the angle at which the hand stop was held to enable aiming without twisting the wrist,” said Jacquelin. “This way, we solved the problem of limited ulnar deviation angle. In the second step, we increased the area of contact between the hand stop and the palm to provide more stability in a position our client had not trained for.”

Due to the winter nature of the athlete’s sport, the material the hand stop was to be printed in needed to be able to withstand sub-zero temperatures. Generally, the majority of polymers perform poorly in freezing temperatures, losing some of their mechanical properties and becoming brittle. Athletics 3D identified BASF’s PP Ultrafuse GF30 as an exception, though.

The material is a polypropylene-based composite reinforced with 30% addition of glass fiber that, alongside its grippy surface and mechanical strength, delivers excellent surface quality to parts.

“World Cup biathlon races are done in temperatures as low as -25°C, the is the winter sport after all,” explained Jacquelin. “And such low temperatures tend to degrade the mechanical performance of most polymers. Materials such as PLA or even ABS tend to become brittle when it’s freezing, that’s why the French team coaches insisted on choosing the material that could perform in low-temperature conditions.

“Thanks to BASF Ultrafuse PP GF30 we had no problem with that. The material exhibited the same excellent performance in both freezing cold and relatively mild temperatures just below 0°C.”

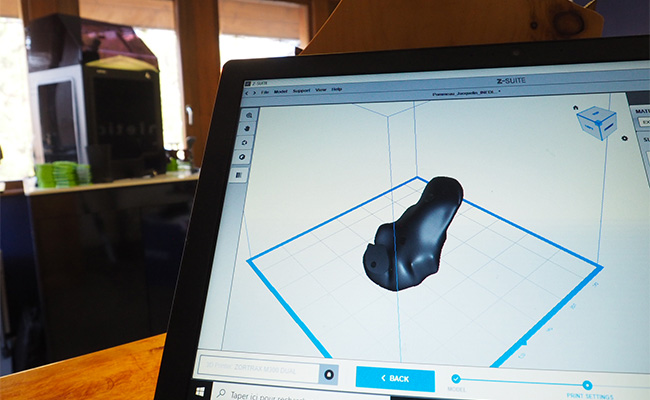

The custom hand stop was then 3D printed on a Zortrax M300 Dual 3D printer, which thanks to its ability to accurately reproduce irregular shapes, enabled Athletics 3D to achieve the excellent surface quality desired by the French national team. The firm selected the M300 due to it being factory-calibrated to work with BASF Ultrafuse PP GF30, and because the printer’s Z-SUITE software comes with predefined profiles and settings for printing with the material.

“Professional sports are very often used as a testbed for new, innovative technologies,” said Mariusz Babula, Zortrax CEO. “3D printing is no exception. We are proud the Zortrax 3D printers working with materials coming from world-leading manufacturers such as BASF Forward AM can deliver the performance necessary at the very pinnacle of disciplines like biathlon.”

Shooting for gold

The athlete began training with the 3D printed hand stop in September last year over a two-month period. The results, according to Zortrax, were “impressive, considering the circumstances.” In fact, the French team coaches found that shots taken with the modified hand stop were even more precise than those taken with the original.

However, although shot accuracy increased, the athlete’s shooting rate decreased using the 3D printed hand stop. Once full movement was restored in the athlete’s wrist, the team decided to revert back to the standard hand stop.

“The main reason was that the coaches together with our client decided that increased accuracy did not offset the slower shooting rate,” said Jacquelin.

“However, getting back to shooting and competing in World Cup races was made possible at least two months before it normally would have without our 3D printed hand stop.”

Olympic-standard 3D printing

Athletic 3D’s 3D printed hand stop was not additive manufacturing’s only contribution to the 2022 Winter Olympics. In the run-up to the games, 3D printing featured heavily in the BBC’s advert for the sporting event, while 3D printer manufacturer Farsoon developed 3D printed ice skating blades for the Chinese short track speed skating team.

A range of 3D printed parts, equipment, and sportswear was on show at the 2022 Tokyo Olympics, too, such as the Great Britain Cycling Team’s new track bike and Adidas’ 3D printed Futurecraft STRUNG running shoe.

Additionally, the Korean archery team was helped onto the podium by 3D printed grips from Hyundai Motor Group and a 3D printed rudder blade suspension from Fehrmann Alloys propelled the Australian Sailing Team to victory during the games.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows a professional biathlon rifle with the 3D printed custom hand stop attached. Photo via Zortrax.