Acoustical engineer Peter Riccardi has designed his own laboratory-grade microphone that can be 3D printed and assembled for less than $30.

High-end lab-grade microphones are elementary tools in the arsenal of an acoustician or acoustical engineer, providing the level of performance necessary to capture precise physical signals during experiments. Unfortunately, a conventional condenser microphone can cost around $1000 from a reputable manufacturer like PCB Piezotronics, rendering such projects heavy on the wallet.

Writing on his Hackaday project page, Riccardi says, “The quality of such microphones is superb, but there are alternatives available to the hobbyist and enthusiast which will get you comparable performance for a fraction of the cost.”

Featuring a 3D printed shell and four internal MEMS microphones, Riccardi’s homegrown device is intended to be an accessible alternative to those higher-end systems. Despite only costing $30, the microphone is designed to offer a similar noise floor, frequency response, flatness, and sensitivity in the audio band of 20Hz to 20kHz.

Designing and 3D printing the microphone

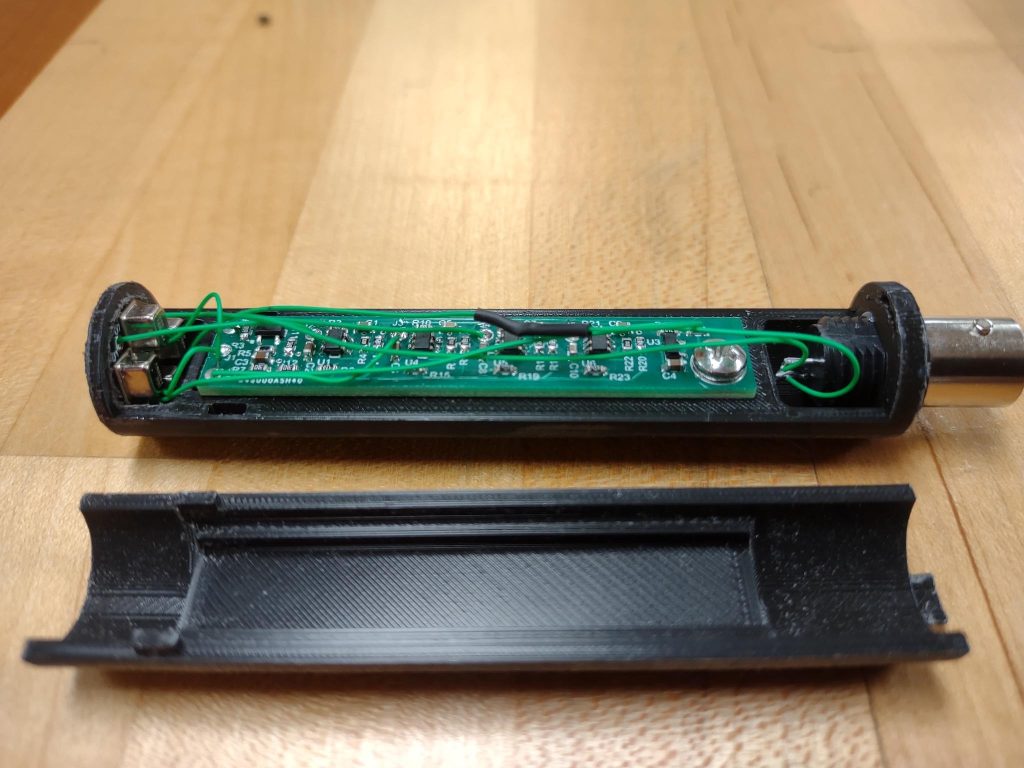

For his prototype, the engineer split the electronics into two boards, the first of which is the MEMS carrier board. Four MEMS microphones were mounted onto a circular PCB which included a series of small through-hole pads for all of the required power and signal connections. The second board is the motherboard, which houses all of the inputs and signal conditioning for the MEMS outputs.

The boards then needed to be fixed to a mechanical assembly – this is where 3D printing comes in. Riccardi designed a simple cylindrical casing in SolidWorks and 3D printed the assembly in two parts using PLA. The shape and size of the chassis were designed to mimic commercially-available microphones at just 0.5” in diameter.

He adds, “Since the entire mechanical assembly is an arc, it is quite rugged and can be tossed around without fear of damaging or cracking the case. The opening for the MEMs carrier board will need future modifications as there is very little material and large stress concentrations acting on the layer-to-layer bonding. For now, it works just fine though.”

Did it out-perform a commercial microphone?

The decision to use four MEMS microphones at once was a deliberate one. Electrical systems with components that have voltage drops across them will inevitably produce electrical noise, which disrupts signals and makes them harder to read. This noise is random but it can be averaged out to reduce its effects.

By tying four MEMS elements (noise sources) together in parallel with small resistors, the output noise floor of the microphone can be reduced, thereby increasing the signal-to-noise ratio of the system with little effort. Typical condenser microphones have excellent signal-to-noise ratios with sensitivities of around 50mV/Pa.

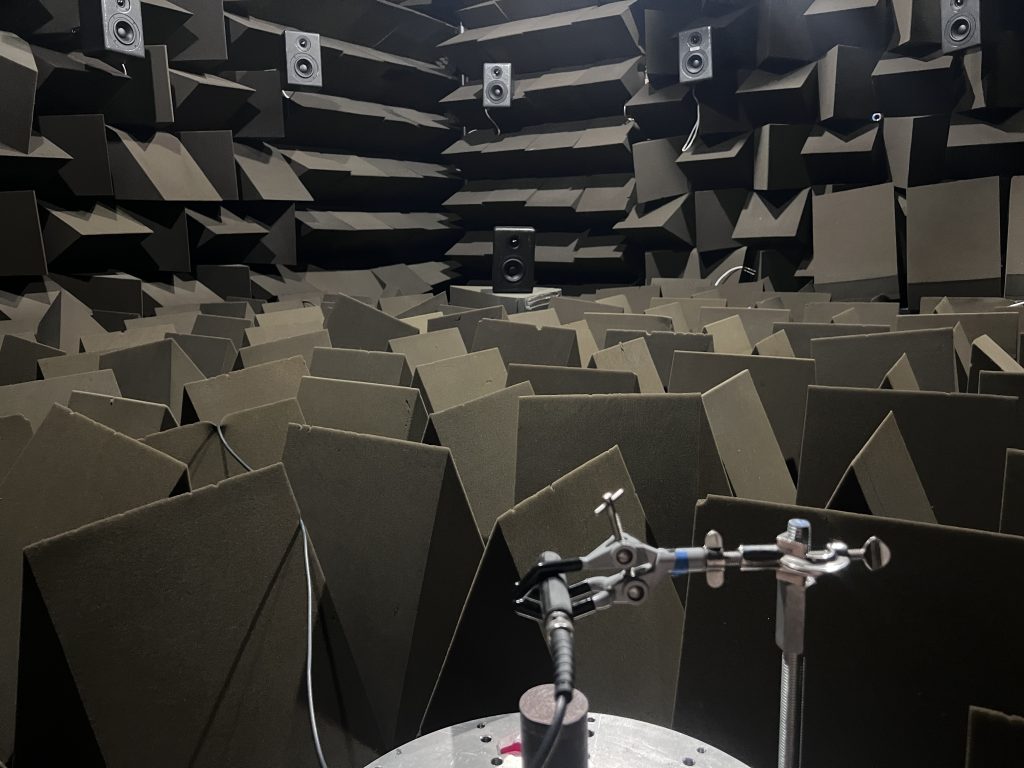

The test the performance of the 3D printed microphone, Riccardi put it through its paces in a semi-anechoic chamber (a very quiet room). He used a National Instruments NI 4431 data acquisition system to compare the frequency response and noise measurements of the device against a PCB Piezotronics 378B20 free-field condenser microphone.

The results were impressive to say the least. Riccardi’s low-cost microphone had a frequency response sufficiently flat in the audio band, while its sensitivity was shown to be high enough for real-world measurements, albeit less than the PCB offering. However, below 200Hz, the performance of the 3D printed microphone was actually found to be slightly better than its commercial counterpart.

He writes, “Additional experimentation needs to be done to more rigorously characterize the microphone. But, the preliminary results are very promising and the price makes it impossible to ignore.”

Details and downloadable files for the 3D printed microphone can be found on Riccardi’s Hackaday project page.

The rise of consumer-grade 3D printing technology has enabled creatives and hobbyists everywhere to develop accessible versions of products at comparatively low costs. Earlier this year, hobbyist toymaker Riskable developed an innovative new key switch mechanism for use in PC keyboards. Named ‘Void Switch’, the magnet-based design is completely open-source and can be fabricated at home with any run-of-the-mill FFF 3D printer.

Elsewhere, YouTuber Akaki Kuumeri has previously designed and 3D printed a novel joystick attachment for his Xbox Series X/S controller, turning it into a fully functional flight stick. More recently, he went on to build an open-source library of 3D printable parts that attach to game controllers to enable non-standard hand positions, making playing video games more accessible to those with physical disabilities.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed microphone. Photo via Peter Riccardi.