Researchers from the University of Birmingham, UK, have proposed a new approach to design for additive manufacturing, suggesting there is much to learn from the prenatal development of a human baby.

The work by Birmingham’s School of Engineering and the Centre for Human Reproductive Science and published in The International Journal of Advanced Manufacturing Technology highlights how developing biological systems, tissues and organs, are built up incrementally via the division and replication of cells.

The influence of prenatal development on additive manufacturing

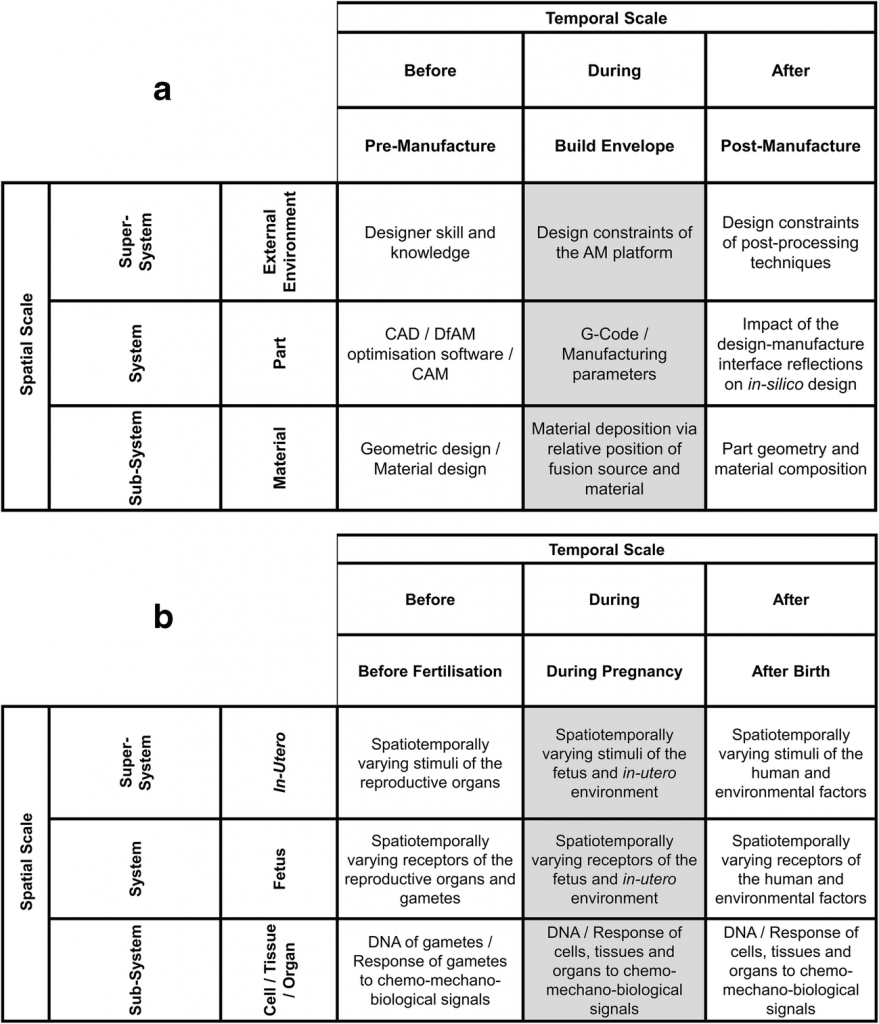

The study notes both growth rate and region of growth change during pregnancy. Conversely, in additive manufacturing, the development or “growth” of a 3D printed part is solely reliant on the spatial domain, determined only by where the filament is deposited. In this regard, the temporal dimension (aka time) is an inoperative process variable when it comes to design for additive manufacturing. The study explores how an implementation of the temporal domain could lead to the development of previously unseen material properties and structures.

Previously, researchers have attempted to alter the properties of 3D printed materials but it has been through the spatial variation of the composition of the deposited material, leaving out the temporal domain. This also limits the studied materials to multi-material composites. The methodology of the present study can be applied to single-material filaments.

What do the researchers say?

Lead researcher, Dr. Lauren Thomas-Seale of the Department of Mechanical Engineering, states: “Although we refer to it as additive manufacturing, traditionally engineers learn to design parts based on a long history of subtractive manufacturing. This leads to well-acknowledged constraints in design creativity. Additive manufacturing has to break out of this inertia if it is to reach its full potential in both design and as a fundamental technique.”

Co-author of the study, Dr. Jackson Kirkman-Brown of the Institute of Metabolism and Systems Research adds: “Whilst using biological inspiration in engineering design is commonplace, studying the growth of humans and translating this to advanced manufacturing systems offers a whole new perspective. The way in which biological systems develop from incrementally adding cells to form tissues and organs, which both grow and modulate each other to function in synergy, is the epitome of sophisticated additive manufacturing.”

The study, funded by the Royal Society, is named ‘Temporal design for additive manufacturing’. It is co-authored by Saliba, S., Kirkman-Brown, J.C. & Thomas-Seale, L.E.J..

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Featured image shows a render of the new School of Engineering, currently under construction at the University of Birmingham. Image via the University of Birmingham.