3D printing is still in its, let’s say, adolescence, as new growth spurts push the young field to reach for its full potential. These past few years has seen the technology learn to 3D print with conductive inks, inkjet metal, and produce objects in mere minutes. Now, a new process from Do3D, called Multidirectional Additive Production (MAP), could allow for 3D printing in different directions. Not only has Do3D unveiled their first 3D printer to use this technology, but they also say that MAP can be implemented with both liquid and powder-based processes.

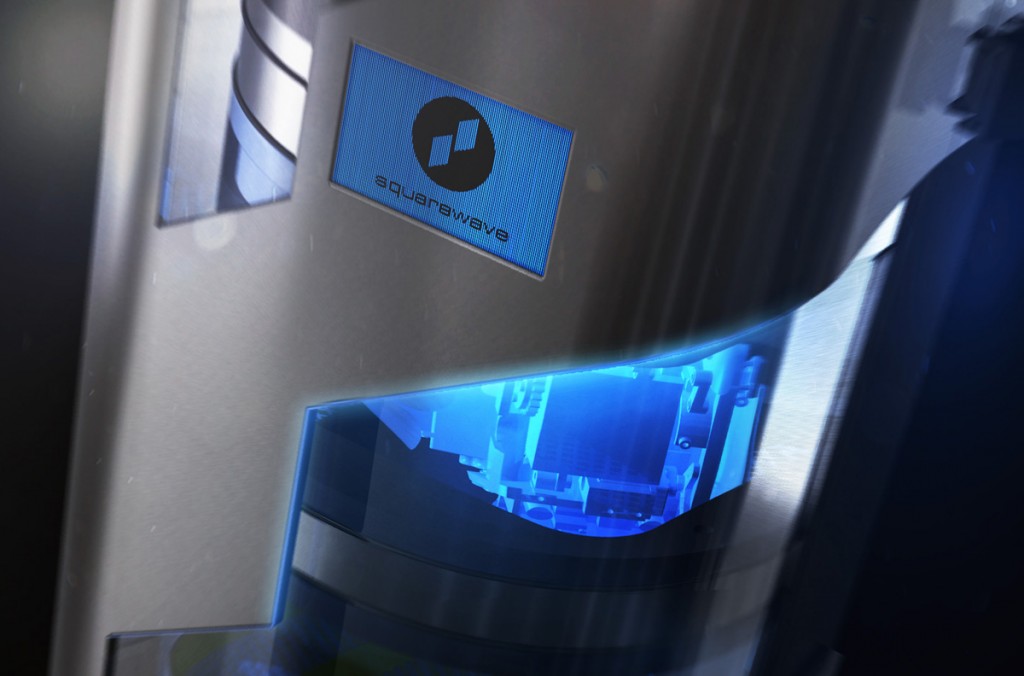

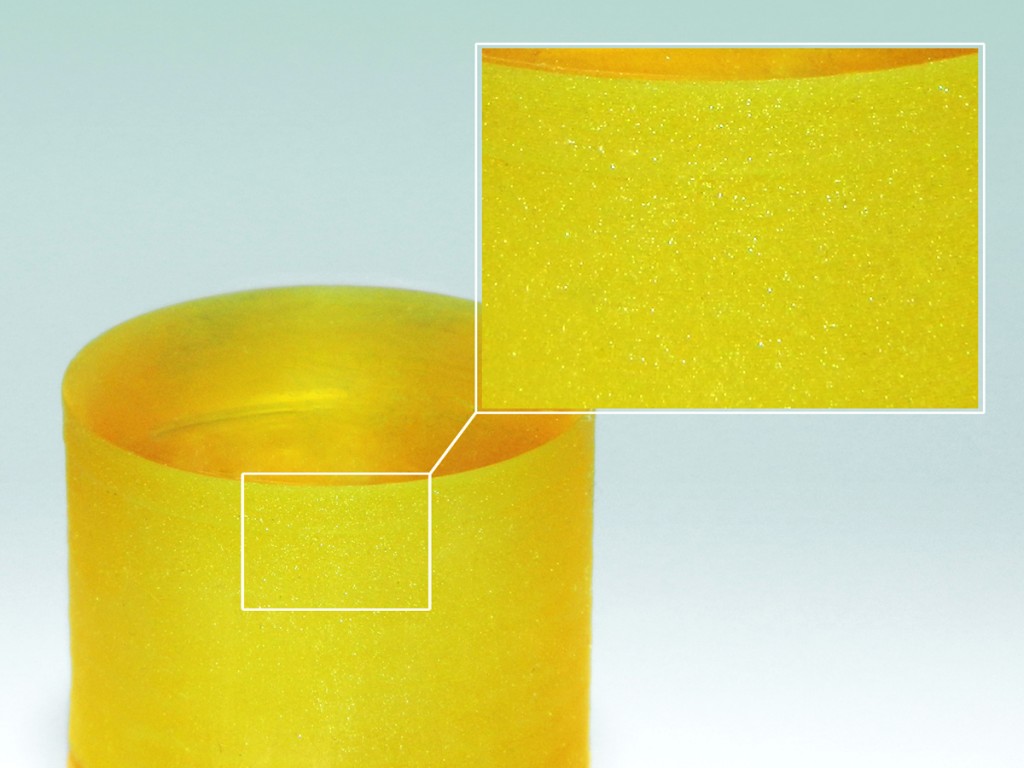

Though their Genesis (G1) DLP 3D printer has been around since 2014, Do3D’s MAP technology could put them on the map. MAP was developed by Do3D co-founder and CTO Marton Bartos as a means of speeding up the 3D printing process through multidirectional fabrication. The patent-pending technology sees a part printed not from one direction onto the build plate, say from the bottom up, but from both sides of the build plate, the bottom up and top down. This results in speeds of 200% or more, but the company believes that they can expand the technique from two sides to multiple sides of the print area, increasing speeds even further. To demonstrate the process, Do3D has created their Squarewave DLP-SLA 3D printer; however, the company believes that the technology can be expanded for powder and thermoplastic filament fabrication as well.

Bartos says of the technology, “We have been asking ourselves how we could achieve multidirectional 3D printing for a couple of years. By rethinking the basic concept of creating physical 3D geometries, we have found solutions that could be implemented in marketable products in the near future. We have filed a patent for this new approach and have proved with concept prototypes that our process is well within reach.” He adds, “The first prototype offers contemporary upward and downward printing and is especially fit for very large parts. Our main goal is to be able to take this idea to the next level and by that we mean establishing potential partnerships in industries that can benefit from our technology. Production speeds achievable with MAP technology could change the face of 3D printing.”

Commercial availability of their MAP technology and the Squarewave 3D printer will be announced later this year. For now, there are few technical details about the process available, with Do3D saying that, because of the pending patent application, they are hesitant to make too much information public. What they can say is that have a set build platform with multiple print heads “working around” it.

Given the existence of multi-axis 3D printing processes and techniques relying on industrial robotic arms, the concept itself is not out of the realm of possibility. The potential impact of MAP 3D printing, however, remains to be seen. As long as it’s real, I’m happy, as it makes for more innovation in the space and, hopefully, an evolution of 3D printing overall. And that our awkward 3D printing teen will grow into a 3D printed adult in no time.