Microsoft has released open-source hardware designs and software for SurfaceConstellations, a semi-rigid modular mobile system using 3D printing.

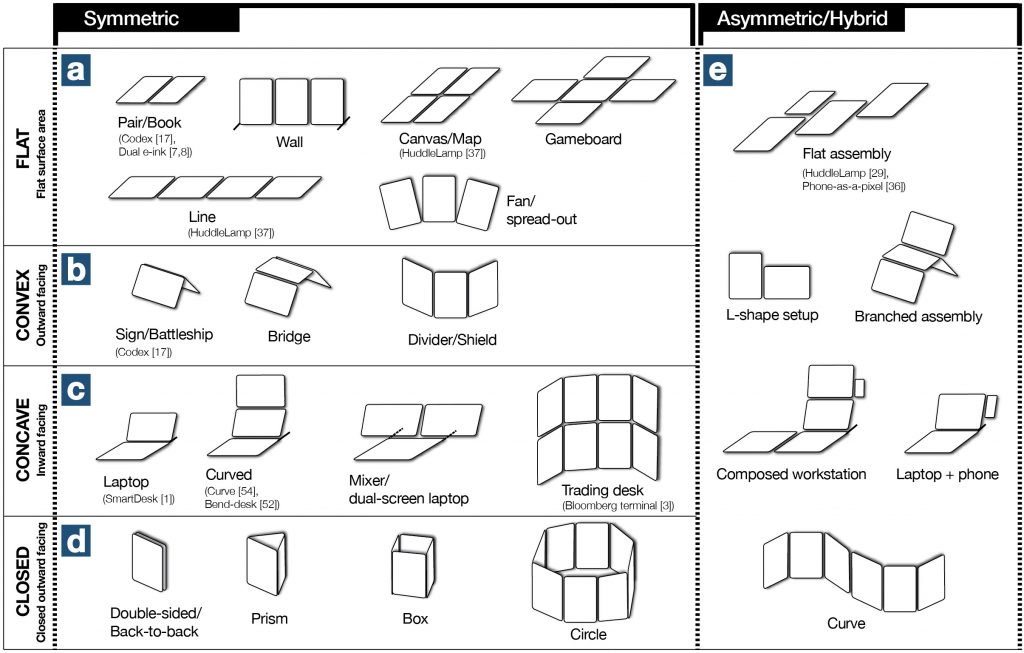

The SurfaceConstellations platform provides an extensive database of 3D printed link modules to configure connected tablets into modular workspaces and includes various setup patterns as well as a visual configuration tool for generating link modules.

Made-to-measure workspaces

The designs were developed by engineers at Microsoft Research and University College London (UCL). They enable users to configure tailored cross-device workspaces by linking multiple tablets with the 3D printed brackets ‘link modules’ that coordinate information between the connected devices.

The researchers have illustrated 23 different configurations involving up to eight screens in a “circle” or “trading desk” setting. Other options include a three-tablet setup for a two-player game, a six-tablet trading desk, and three-tablet setup for multiscreen music editing, a six-tablet wall for a trading desk, and a “composed workstation” combining tablets with a laptop and a smartphone. 3D printed brackets hold each configuration together, and the 30-degree connective angle of the brackets allows for self-standing structures.

Attached to the brackets are capacitive links that help establish a connection between each device. Called “CapacitiveLink” by the research team, this method works by covering a small part of the screen as a unique touchpoint so the conductive material connects the devices more reliably. The researchers explain:

“Similar to capacitive widgets, our brackets are recognized without the need for a person to touch the conductive material. Our 3D-printed bracket design, which includes an inner core of conductive 3D-print material, overlaps with the touchscreens of connected tablets and triggers a touch contact on each screen.”

MyMiniFactory, a social media platform for 3D printable objects, has made the bracket link designs available online, including measurements for multiple devices as Microsoft’s Surface Pro 2, Apple’s iPad Air tablets, an iPad 3, and iPhone 7. MyMinyFactory CEO Romain Kidd commented:

“This clever customisable accessory by Microsoft is a great example of how 3D printing can enhance the capabilities of a core central product, in this case giving more reasons for customers to buy a Surface tablet in the first place.

Much like how Android and iOS have won the mobile platform war by

building the healthiest developer communities (and ironically where

Microsoft lost with Windows phone), the winning physical products of the future will be the ones with access to the best high quatity 3D printable accessories. Through Design Challenges in particular, MyMiniFactory will continue to provide the tools for brands to build out these libraries.”

Open source availability

Open sourcing hardware designs asks the question: what happens when tangible goods become digitalized and free-flowing? According to IP attorney John Hornick, 3D printing is fostering the “democratization of manufacturing.” As he explains open sourcing goes directly against production regulation, and means “the ability to make a part or product without anyone knowing about it or being able to control it”. Michael Weinberg, General Counsel at Shapeways and Open Source Hardware Association (OSWHA) board member, comments that this decade has seen “an explosion of new content that is 3D printable, and a lot of it is tied to open licenses or permissive licenses.” For Weinberg,

“3D printing fits into a larger social legal pattern of technology empowering people to make use of the world around them and there is not a way under traditional IP structures to really deal with that.”

In these circumstances, open sourced content in the public domain remains a debated issue, and 3D printing stands at the forefront of the discussion due to its democratizing potential.

The research, SurfaceConstellations: A Modular Hardware Platform for Ad-Hoc Reconfigurable Cross-Device Workspaces,was conducted by Nicolai Marquardt, Frederik Brudy, Can Liu, Benedikt Bengler, and Christian Holz.

For the latest 3D printing materials news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Advance your career in 3D printing, or post a vacancy. The 3D Printing Jobs board is live.

Voting is still open for 2018 3D Printing Industry Awards.

Featured image shows a modular setup using the 3D printed brackets. Image via Ben Bengler/Microsoft