Welcome to the latest edition of our 3D printing jobs and career moves update for the additive manufacturing sector.

If you are looking for a new position in the industry, we keep our 3D Printing job board updated with the latest positions. You can easily apply to any of the posted jobs after creating a free profile. If you are just about to enter the sector, we offer a guide on how to get a job in the 3D printing industry.

The 3D Printing Industry jobs board is also free to use for employers to find 3D printing experts for their businesses.

Read on for updates on the latest job opportunities at polySpectra and Miller 3D, hires at Essentium, and Purdue University’s new research laboratory.

3D Print Production Manager at polySpectra

Based in Berkeley, California, materials producer polySpectra is hiring a 3D Print Production Manager who will be responsible for managing the flow of 3D printed parts from customer acquisition to print shipment. The successful applicant will be required to work with the company’s sales, R&D, and production departments to evaluate customer requirements and generate accurate quotations for parts.

To be successful for the role, candidates will have a Bachelor’s degree, preferably with a technical focus, and will have knowledge of advanced CAD software, additive manufacturing hardware, and workflows. Production management experience in a manufacturing environment is also essential, as is the ability to communicate effectively, multitask, prioritize workloads, and work in a fast-paced environment.

Candidates interested in the position of 3D Print Production Manager at polySpectra can find the full job description here.

3D Printing Sales at Miller 3D

Miller 3D, a division of Pennsylvania-based A.W. Miller Technical Sales, is looking for a 3D printing salesperson to join its growing team. The successful candidate will be responsible for generating and driving sales for 3D printers and 3D scanning equipment in the company’s Pennsylvania territory, and will be interacting with companies and government agencies across sectors such as education, aerospace, medical, architecture, and general manufacturing, among others.

Miller 3D is looking for someone with a minimum two years’ experience in sales with a proven track record in the area. Applicants will need to demonstrate an ability to exceed in sales, alongside solid experience in opportunity qualification, pre-call planning, and account development. The company is offering between $20-30,000 annual compensation and commission.

Those interested in applying for the role of 3D Printing Sales at Miller 3D can view the full job description here.

Essentium names Jeffrey Lumetta Global Chief Technology Officer

3D printing materials supplier Essentium has appointed 3D printing industry veteran Jeffrey Lumetta to the role of Global Chief Technology Officer (CTO). As the latest senior appointment to Essentium’s executive leadership team, he will spearhead the company’s technology strategy, development, and operations to continue advancing its position in the additive manufacturing sector.

Lumetta brings more 35 years of experience in driving technology innovation, engineering, and volume manufacturing advancements in the industry, with previous stints as principal of an additive manufacturing-specialist management consultancy and three decades with global manufacturing specialist Jabil.

“Jeffrey has an outstanding track record of helping manufacturers leverage AM technology infrastructure to deliver real business value,” said Blake Teipel, CEO of Essentium. “This high-caliber appointment comes at an important time when our team is doubling down on technology advancement across our AM solutions.

“Jeffrey will help drive our customers’ growing adoption of industrial-scale AM, increasing their resilience, lowering costs of operations, and driving innovation into their businesses.”

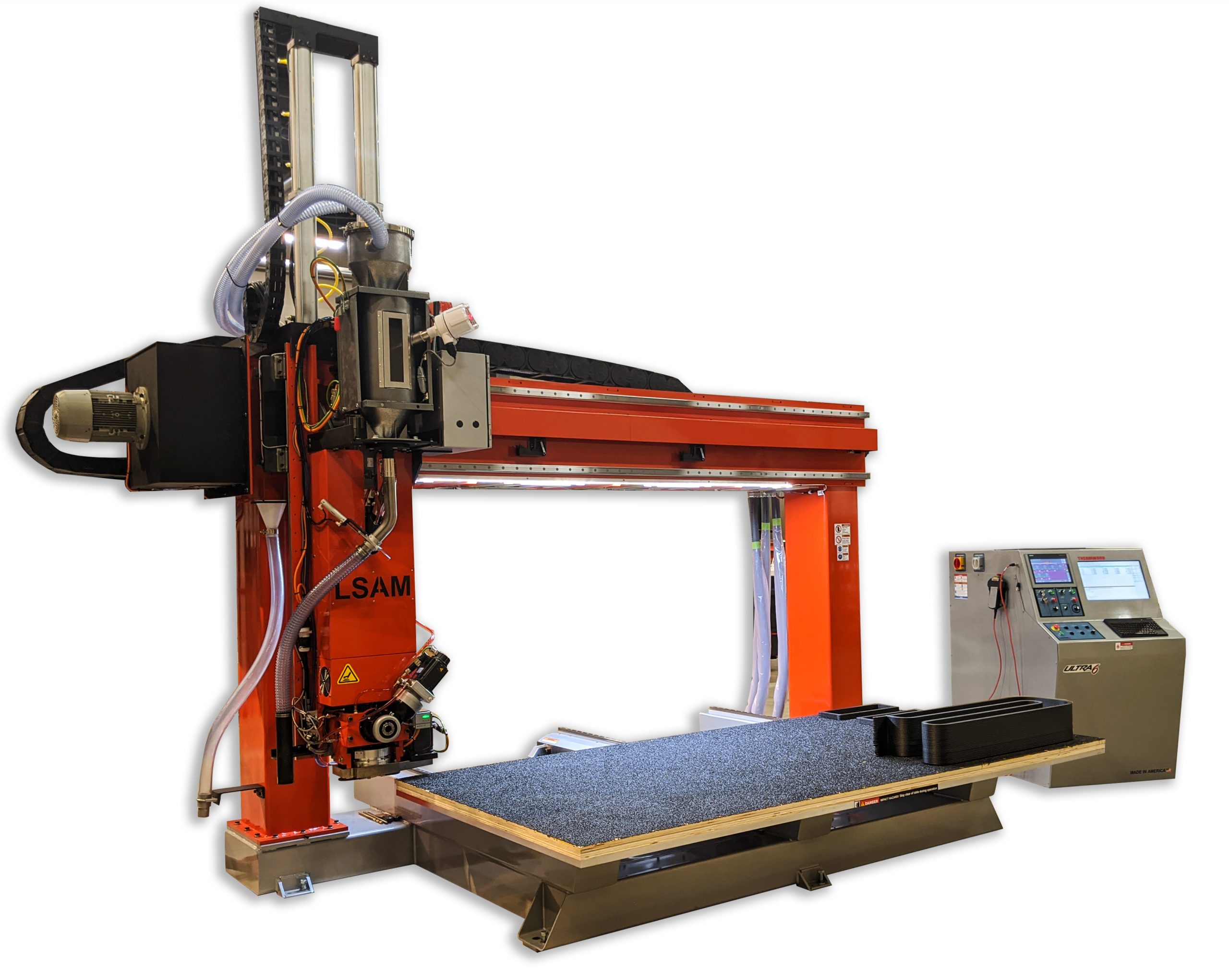

Purdue University and Thermwood to establish LSAM research lab

Purdue University’s Composites Manufacturing Simulation Center (CMSC) and machinery manufacturer Thermwood Corporation have partnered to establish a large scale additive manufacturing (LSAM) laboratory. Located at Purdue’s Indiana Manufacturing Institute, the lab will carry out industry-funded research into large scale composite thermoplastic 3D printing.

The new facility will be equipped with an LSAM 105 3D printer and corresponding 5-axis LSAM additive trimmer and support systems. The installation will be capable of printing and trimming complex geometries up to 5’x10’x4’ at print rates of up to 100 lbs per hour. The system has also been modified to allow testing at higher temperatures than the 450 degrees celsius usually limited on LSAM printers, enabling experimentations with material innovations not normally used in 3D printing.

With the establishment of the lab, the partners are aiming to expand the adoption of LSAM for diverse industrial applications, and will engage with industry players to provide services, refine material formulations, and determine ideal processing parameters necessary to produce high-quality large scale printed parts.

Ken Susnjara, Founder, Chairman and CEO of Thermwood, said: “Not only will this effort improve the overall quality of large scale additive printing but it should also increase our knowledge and understanding of the basic process of fusing layers together into a homogeneous structure.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D Printing Industry Jobs Board.