Engineers at the NASA Jet Propulsion Laboratory (JPL) are set to contribute to the development of a hybrid 3D printing technology from the Advanced Manufacturing Research Centre (AMRC) in Sheffield, UK.

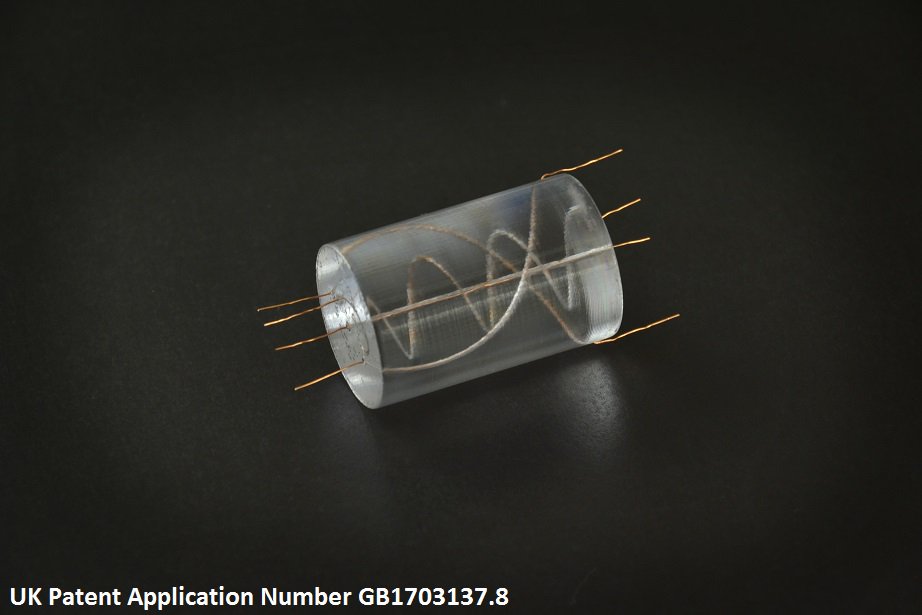

Known as THREAD, this method is capable of adding fibrous electrical, optical and structural elements, or “threads,” to the inside of plastic/polymer components.

It has been developed at the AMRC in collaboration with multinational aeronautical corporation Boeing and, according to creators, it is a “a potential game-changer” for 3D printing and the wider manufacturing industry.

THREAD hybrid additive manufacturing

The first details of Boeing and AMRC’s THREAD process surfaced in 2017 following a patent-filing by the method’s inventor Mark Cocking. At the time of this release, 3D Printing Industry interviewed Cocking who revealed that the technique is “not tied to a single AM process platform,” though initial patents relate to its addition to an SLA technique.

Overall, Cocking added, THREAD is a process that “embeds strand material of differing material groups i.e. copper, fiber optic, steel, nitinol, etc.”

“Single or multiple strands can be embedded at a rate that does not effect the original build time of the component, no matter the process,” he says,

“There is no need to stop, pause, remove, re jig or post process.”

Based on these initial claims of the process, NASA-JPL invited Cocking to present the THREAD method at its recent Spacecraft Additive Design Workshop in Pasedena, California.

NASA ‘extremely impressed’

At the NASA-JPL workshop, Cocking demonstrated how THREAD could be applied to make functional components for a space rover. This led to the resounding approval of NASA-JPL Spacecraft Design Senior Engineer Michael Schein, who called the technology “extremely impressive.” Now Schein has expressed interest “in the further development of the THREAD process for embedding fibres in 3D printed materials […] especially if it can be adapted to metal printing.”

In addition to further THREAD development in the polymer sphere, Cocking is currently adapting the process for metal selective laser melting (SLM). He adds, “THREAD has potential applications across many sectors such as energy, medical and aerospace; where components would benefit from integrated power, data, and fluid transfer, such as for the design of spaceflight assemblies.”

Nominate the AMRC, Mark Cocking, THREAD technology or other standout projects in the 2019 3D Printing Industry Awards now.

For more additive manufacturing news updates subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows a part produced using the THREAD hybrid 3D printing process. Image via the AMRC.