The UK’s Manufacturing Technology Centre (MTC), located in Coventry, has revealed the results of its two-year project, FlexiFinish, which aims to provide an automated additive manufacturing post-processing solution for metallic components.

The FlexiFinish solution

Launched in 2016, and led by TTL, a Buckinghamshire-based supplier of CAD/CAM, CNC machining technology, the FlexiFinish project sought to address the poor surface finish quality of metal parts produced through additive manufacturing.

According to the MTC, a lack of post-processing solutions for metal components with complex geometries has led to a major barrier to additive manufacturing adoption, particularly in demanding end-use applications, such as the civil aerospace industry.

As a result, partners of the FlexiFinish project, have combined multiple post-processing procedures, in-process inspection, robotics, CAM, and process modelling tools into one cell system to streamline additive manufacturing finishing operations.

With this system, the consortium, which includes Sandwell UK, JRI, Meggitt, and GE Power, hopes to reduce industrial production time and costs while increasing repeatability.

The FlexiFinish cell

According to Katy Milne, Chief Engineer at the MTC, post-processing procedures are not limited to just one step and are highly manual. Thus, the FlexiFinish cell takes a more “user-friendly” approach for finishing metal components.

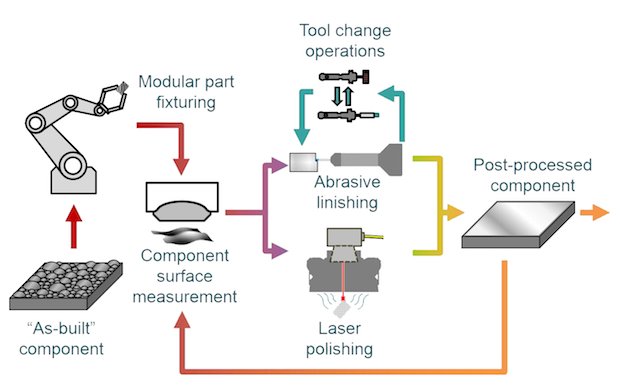

The FlexiFinish system is encompassed within a centralized cell controlled through Human-Machine Interface (HMI). Using Alicona surface measurement software, a 3D printed metal component is fixed within the cell system using a robotic arm.

The surface properties of the component are then analyzed and given a range of post-processing and tool change options. This includes including abrasive linishing – grinding or sanding techniques used to improve the flatness of a surface – and laser polishing.

The component can then be removed from the fixture or sent back to the beginning of the process for further analysis and post-processing.

Aimed for advanced sectors

Following successful testing, the MTC announced that the FlexiFinish system will be aimed towards the aerospace and medical sectors as these industries demand reliability and repeatability of parts.

The MTC have also targeted the aerospace sector with the ongoing DRAMA project which aims to improve the UK’s aerospace supply chain using a unique additive manufacturing digital learning factory.

In addition, the MTC announced plans to establish an Additive Manufacturing Benchmarking Center (AMBC)with the European Space Agency (ESA) to create a “one-stop shop” for resources and to assess the use of 3D printing for ESA high-tech projects.

Stay updated with the latest 3D printing news in aerospace by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the FlexiFinish cell system. Image via the MTC.