Researchers and engineers at Massachusetts Institute of Technology (MIT) are using 3D printing to develop soft, flexible brain electrodes using a conductive polymer liquid material.

Carrying out research into the 3D printing of conducting polymers, MIT engineers are working on developing soft neural implants that conform to the brain’s contours and monitor activity over longer periods, without aggravating surrounding tissue.

Brain implants, typically made from metal, can cause inflammation and the buildup of scar tissue. The use of 3D printed flexible polymer electronics can potentially provide a softer, safer and faster alternative to existing metal-based electrodes designed to monitor brain activity. Therefore, the research could also be useful for developing brain implants that stimulate neural regions to ease symptoms of epilepsy, Parkinson’s disease, and severe depression.

3D printed conducting polymers

In the recently published study, the MIT research team, led by Xuanhe Zhao, a professor of mechanical engineering and of civil and environmental engineering, outline a method of 3D printing neural probes and other electronic devices that are as soft and flexible as rubber. The research is centered on conducting polymers, which are a class of polymers with intrinsic electrical conductivity. They are used commercially as antistatic coatings, as they can effectively carry away any electrostatic charges that build up on electronics and other static-prone surfaces.

“These polymer solutions are easy to spray on electrical devices like touchscreens,” comments Hyunwoo Yuk, a graduate student in Zhao’s group at MIT. “But the liquid form is mostly for homogenous coatings, and it’s difficult to use this for any two-dimensional, high-resolution patterning. In 3D, it’s impossible.”

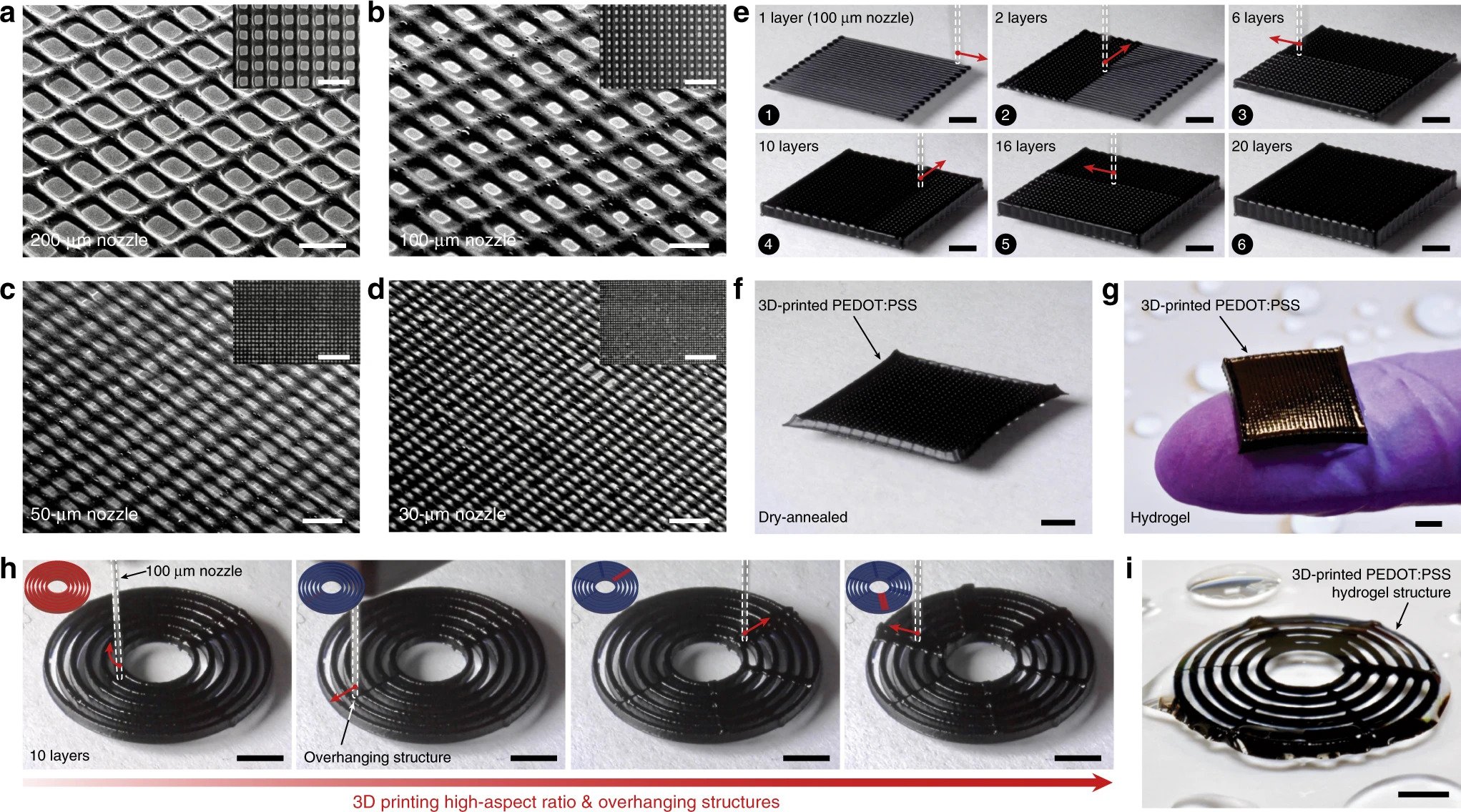

In the paper, the researchers introduce a 3D printable conducting polymer ink solution based on poly (3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS). Normally a liquid-like conducting polymer solution, it contains nanofibers which provide the conductive properties of the material. The MIT team transformed the substance into a thicker material more akin to “viscous toothpaste” in order to make it 3D printable, while still retaining the material’s inherent electrical conductivity.

The process of making the PEDOT:PSS solution compatible with 3D printing involved freeze-drying the material, removing the liquid and leaving behind a dry matrix of nanofibers. These nanofibers were then mixed with a solution of water and an organic solvent, which they had previously developed, to form a hydrogel embedded with nanofibers. Experimenting with different hydrogel formations, the researchers found that a range between 5 to 8 percent by weight of nanofibers produced a toothpaste-like material that was both electrically conductive and suitable for feeding into a 3D printer.

“Initially, it’s like soap water,” Zhao states. “We condense the nanofibers and make it viscous like toothpaste, so we can squeeze it out as a thick, printable liquid.”

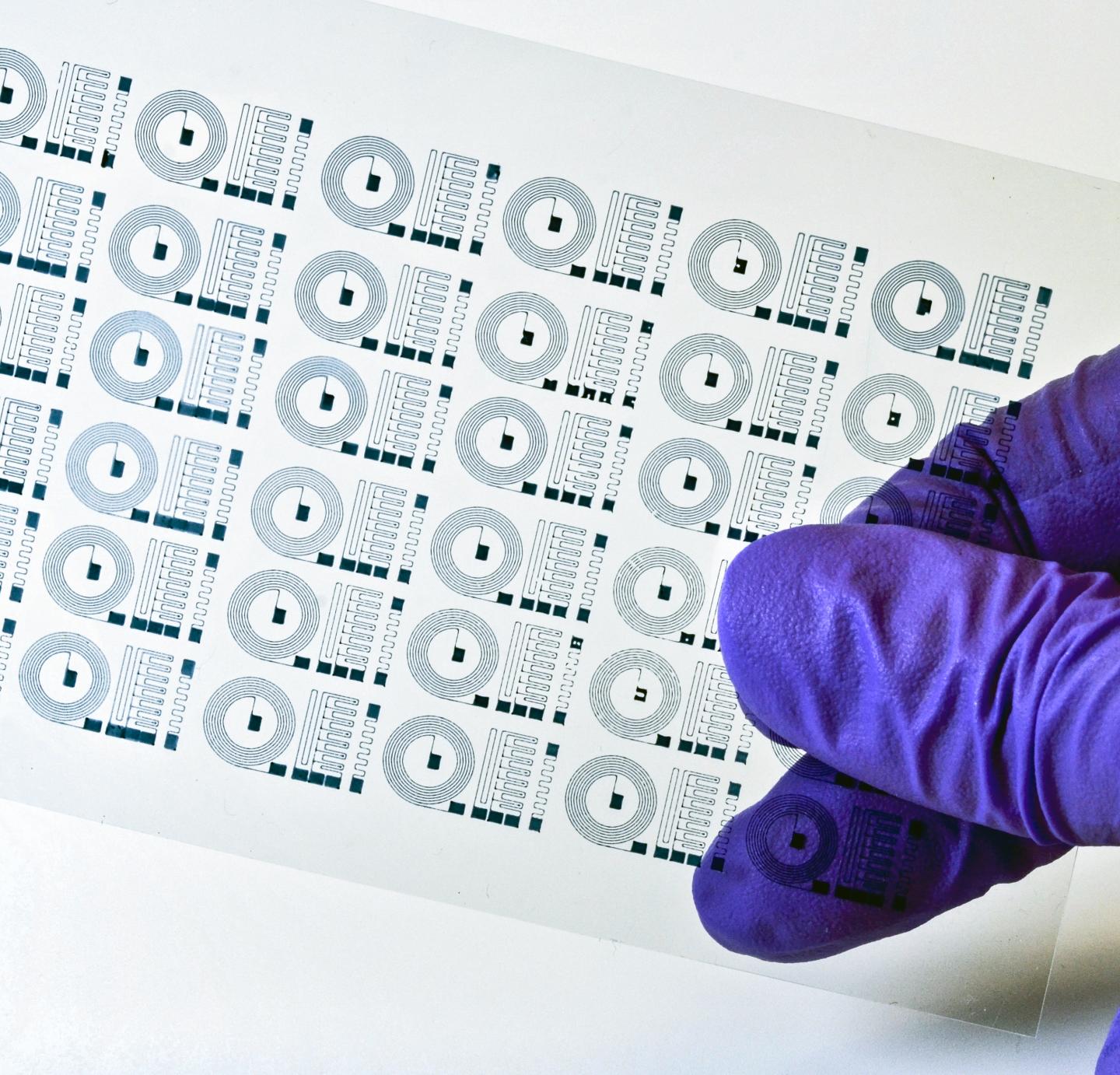

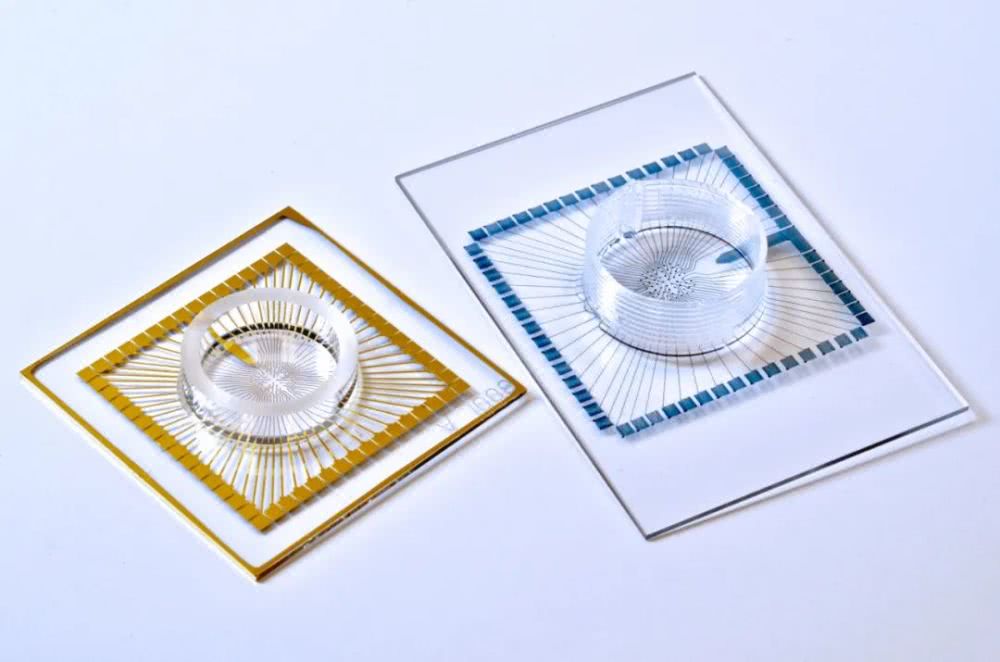

By feeding the new, thicker conducting polymer into a 3D printer, the researchers were able to fabricate stable, electrically conductive patterns. As such, the team used the PEDOT:PSS solution to create several conducting polymer devices, including a soft, rubbery electrode, which they implanted in the brain of a mouse, as a proof of concept.

“We hope by demonstrating this proof of concept, people can use this technology to make different devices, quickly,” adds Yuk.

“They can change the design, run the printing code, and generate a new design in 30 minutes. Hopefully this will streamline the development of neural interfaces, fully made of soft materials.”

Testing the 3D printed electrode

The small electrode consisted of a layer of flexible, transparent polymer, over which the MIT team 3D printed the PEDOT:PSS material, in thin, parallel lines that converge at a tip, measuring about 10 microns wide. Its size ensured the electrode’s capability to pick up electrical signals from a single neuron – the cells that transmit information in the brain using electrical impulses. From the tests, the researchers found that the implanted electrode was indeed able to detect electrical signals from a single neuron within the brain of the mouse as it moved freely in a controlled environment.

Standard neural implants use metal electrodes to stimulate and monitor parts and structures of the nervous system. This can give scientists a higher-resolution picture of the brain’s activity, and can help in tailoring therapies and long-term brain implants for a variety of neurological disorders, like Parkinson’s disease.

As well as potentially causing damage to brain tissue in the event of vibrations, in principle metal electrodes are less sensitive to the electrical signals in the brain compared to hydrogel-based electrodes. This is because metal electrodes conduct electricity in the form of electrons, whereas neurons in the brain produce electrical signals in the form of ions – which means ionic currents require conversion before it can be registered by a metal electrode. This can potentially lead to some part of the signal getting lost in translation. In contrast, the 3D printed soft electrode is made from electron-conducting nanofibers, embedded in a hydrogel — a water-based material that ions can freely pass through.

“The beauty of a conducting polymer hydrogel is, on top of its soft mechanical properties, it is made of hydrogel, which is ionically conductive, and also a porous sponge of nanofibers, which the ions can flow in and out of,” comments Baoyang Lu, a co-author on the study. “Because the electrode’s whole volume is active, its sensitivity is enhanced.”

3D printing in the field of neural implants

Although unique in its use of conductive polymers, the MIT research team led by Zhao are not the first to use 3D printing to create neural implants.

Previously in 2019, researchers at Carnegie Mellon University unveiled a study using 3D nanoparticle printing to create high-density neural probes to record neurological data. The project received a $1.95 million grant from the National Institutes of Health (NIH).

Two months later, Qrons, a New York-based biotechnology start-up, announced an Intellectual Property (IP) License Agreement with Dartmouth College, New Hampshire, to develop 3D printable implants to treat penetrating or traumatic brain injuries (TBI).

The MIT study, “3D printing of conducting polymers” is written by Hyunwoo Yuk, Baoyang Lu, Shen Lin, Kai Qu, Jingkun Xu, Jianhong Luo & Xuanhe Zgao. It is published in Nature Communications.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.