European developer and manufacturer of missiles MBDA has chosen Prodways Rapid Additive Forging (RAF) system to 3D print large titanium aeronautic parts. With the RAF system, which operates using a robotic head depositing molten metal in an atmosphere of inert gas, MBDA intends to reduce costs and lead-times of such components by 25%.

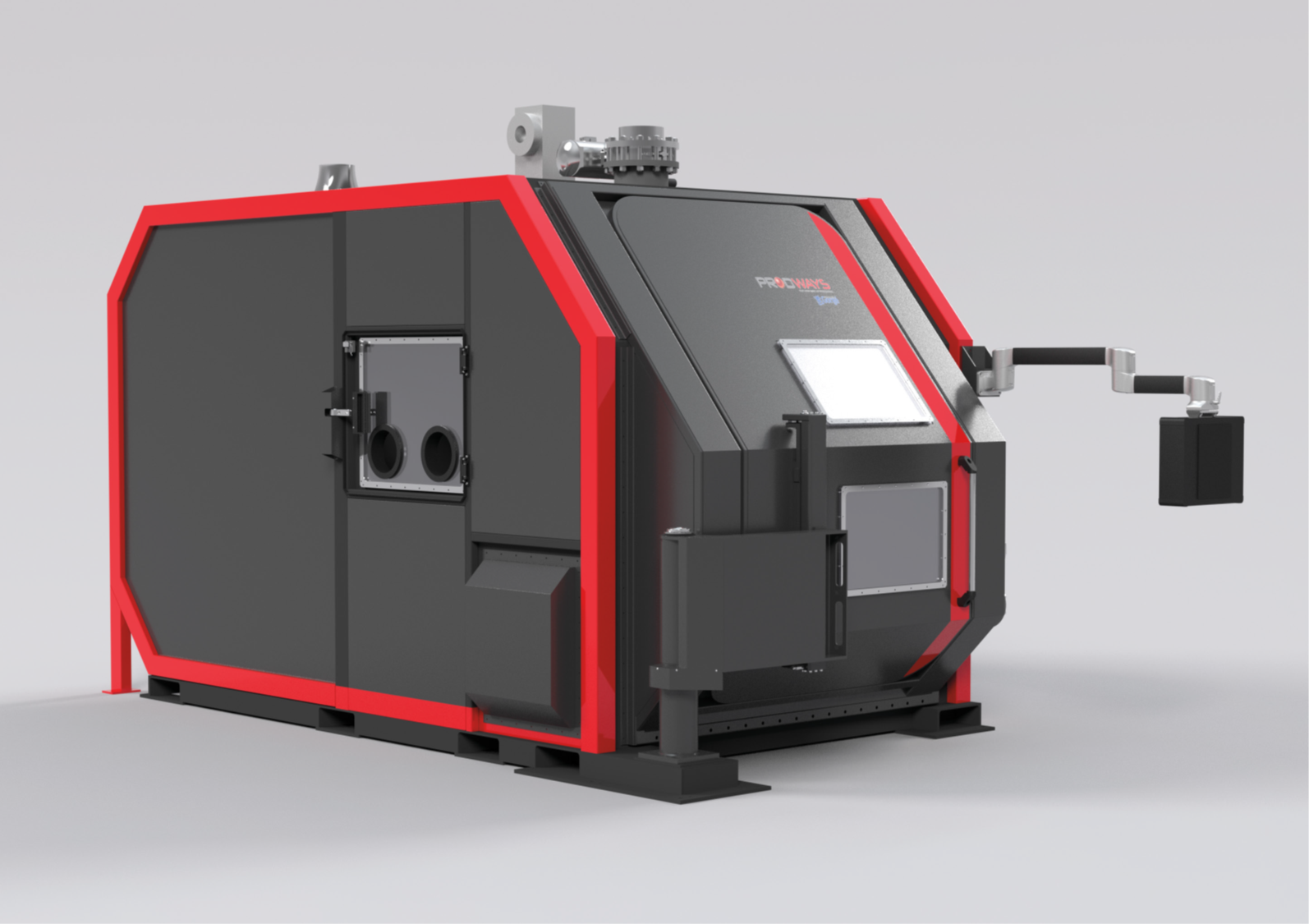

The Rapid Additive Forging system

In 2017, on the eve of the International Paris Air Show, the RAF system was introduced in collaboration with Commercy Robotique, a subsidiary of Groupe Gorgé, the French industrial engineering and technology organization also responsible for Prodways. Of the partners, Commercy Robotique specializes in robotized welding and has more than 40 years of experience.

The RAF system is capable of 3D printing various metals in models of more than 70 cm in size. An RAF 3D printer purchased by precision mechanic and hard metal machining specialist Nexteam Group features a 1200 x 800 x 500mm printing bracket. This technology speedily manufactures titanium blanks with very similar geometry compared with the final part which is then machined.

Large-scale 3D printed parts can be manufactured using the system within a few hours. According to Prodways, aeronautical companies believe this technology can be applied to “nearly 50% of the titanium parts used to manufacture an aircraft and generate savings of up to 50% on the cost of parts.”

Prodways and the Defense sector

Prodways is also active in the defense sector with its SLS 3D printers. Earlier this month, the company revealed that the French Army will be integrating two of its ProMaker P1000 3D printers into its operations. The systems were ordered by the Integrated Structure for Maintaining Land Equipment in operational condition (SIMMT), a division of the French Army focusing on the operational maintenance of land equipment.

More specifically, SIMMT will equip the P1000 3D printers to produce spare parts in real conditions as well as from the 13th Material Support Base (BSMAT). Both systems aare expected to be delivered to the French Army this summer.

Currently, the Prodways RAF system is present at 2019 International Paris Air Show until June 23rd, 2019 at the Le Bourget Parc des Expositions (hall 2B, booth F121).

Stay abreast of the latest additive manufacturing news by subscribing to the 3D Printing Industry newsletter and follow us on Twitter and Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

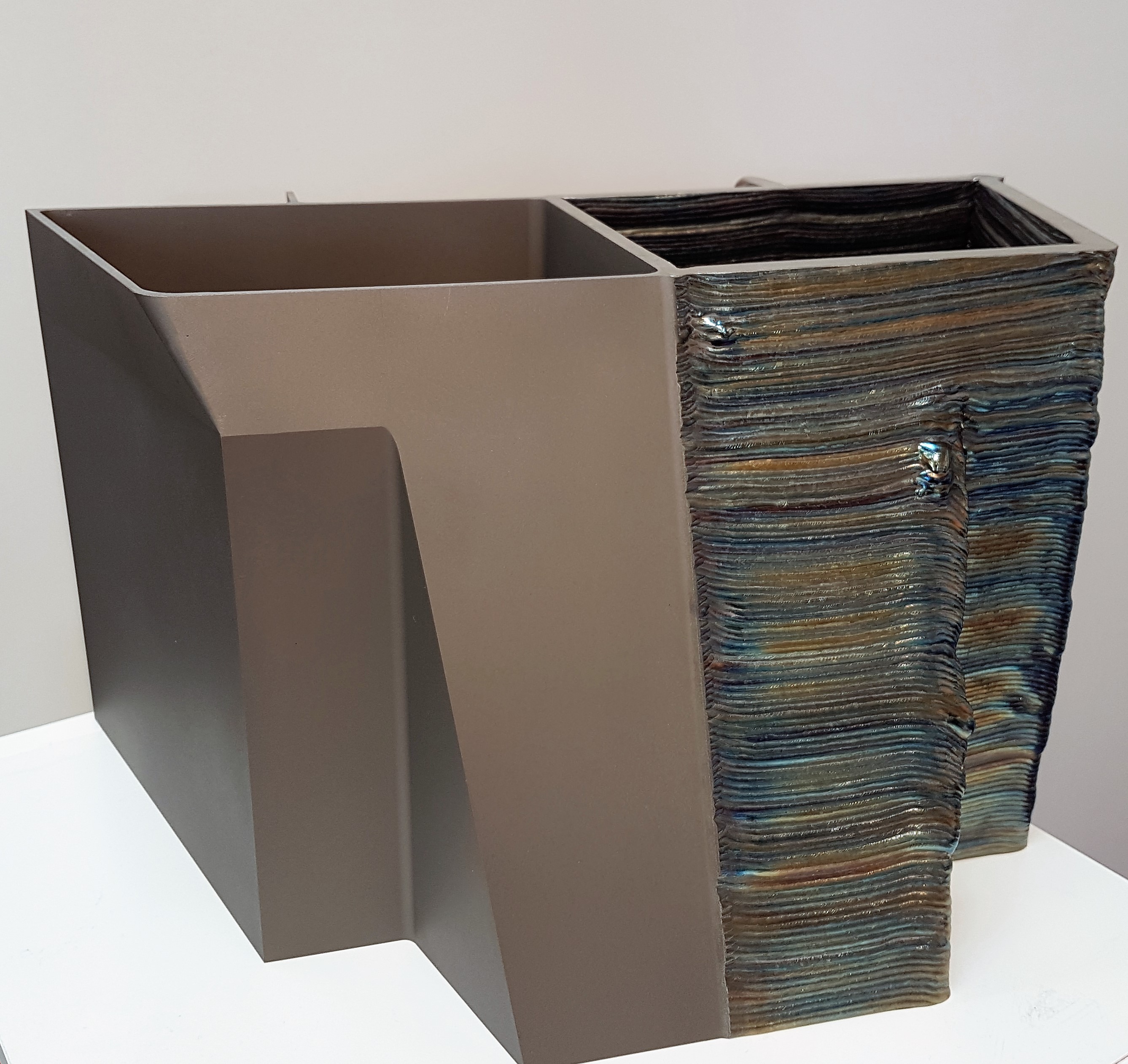

Featured image shows a 3D printed titanium part processed and finished on the RAF system. Photo via Prodways.