Like 3D printing, human-robot collaboration is, according to KUKA, “a decisive principle of Industry 4.0.” Capable of handling payloads well over 1 ton, robotic arms manufactured by the Chinese-owned German company are installed in automotive, electronics and aerospace factories all over the world. They helping human workers in everything from assembly, to welding, and construction projects such as those at Branch Technology and the IAAC.

In product development centers, KUKA has introduced a unique human-robot and 3D printer collaboration with MakerBot. At the KUKA Development and Technology Center in Augsburg, Germany, collaboration by the MakerBot Replicator Z18 earned the 3D printer the title “Employee of the Year” for tireless performance in early-stage functional prototyping, and production of custom-made grippers.

Unstoppable 3D printing

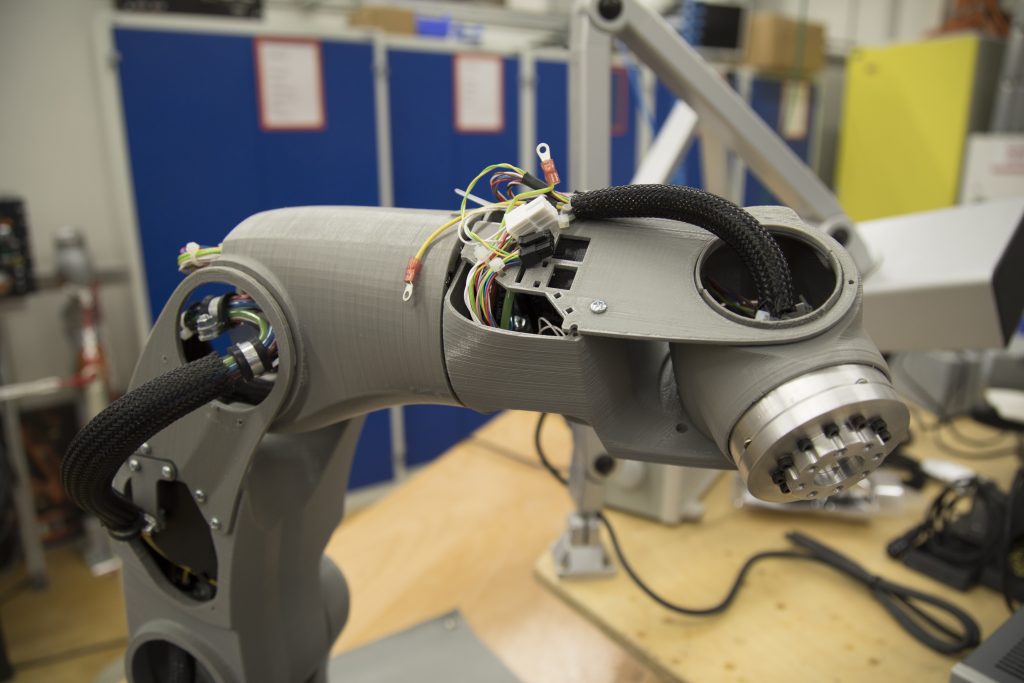

One of the roles of MakerBot 3D printers at KUKA is to make 1:1 scale components for new robotic arms. With these plastic parts, the development team can test the functionality of made-for-purpose robotic arms in lieu of finished steel parts from the supplier.

“By the time we have actual aluminium or metal parts, we have already made a number of revisions,” explains Sören Papsdorf, Head of Manufacturing Engineering at KUKA.

A second job for the Replicator Z18, is to aid in the development of grippers and fixtures, tailor-made for a different purposes such as pick and place or sorting.

“Our printer is working nearly 24 hours,” adds Thomas Schmidberger, KUKA Application Engineer, “In 2016, we printed nearly 7,000 hours with one one printer. We had a success rate of 92%. To us, it is very important that a 3D printer is reliable.”

The future of robotics

In another project, KUKA Industries are working with the German Federal Ministry for Education and Research (BMMF) to develop a new form of large format metal 3D printing. The arms are also used inside Stratasys’ Robotic Composite 3D demonstrator. KUKA robots are also used for inspection purposes in metal manufacturing industries.

“I think human-robot collaboration is the future of robotics,” states Papsdorf, “Human-robot collaboration allows you to combine the advantages of a robot with the advantages of a human being. Seeing, feeling, being able to react quickly.”

Download the KUKA LBR iiwa 7 R800 scaled .stl on Sketchfab here.

Stay up to date with KUKA and MakerBot progress. Subscribe to the most widely read newsletter in the industry here, like 3D Printing Industry on Facebook and follow us on Twitter.

Think KUKA deserves more than just Employee of the Year? Make a nomination now in the 2018 3D Printing Industry Awards.

Featured image shows inside the KUKA Development and Technology Center in Augsburg. Photo via KUKA